Passive cooling separation type heat pipe arrangement structure in spent fuel pool

A passive cooling, separate heat pipe technology, used in cooling devices, nuclear power generation, reactors, etc., can solve the problem that the heat exchange capacity of a single heat pipe cannot meet the requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

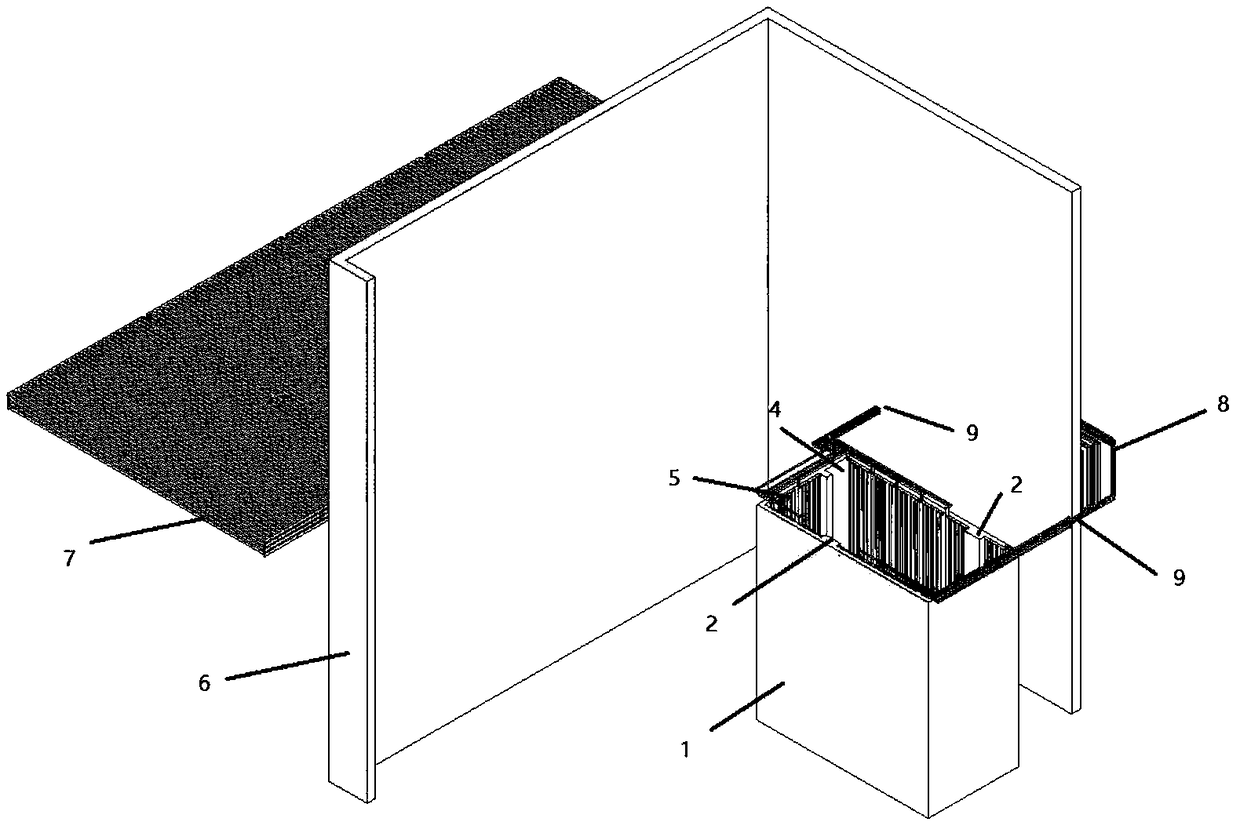

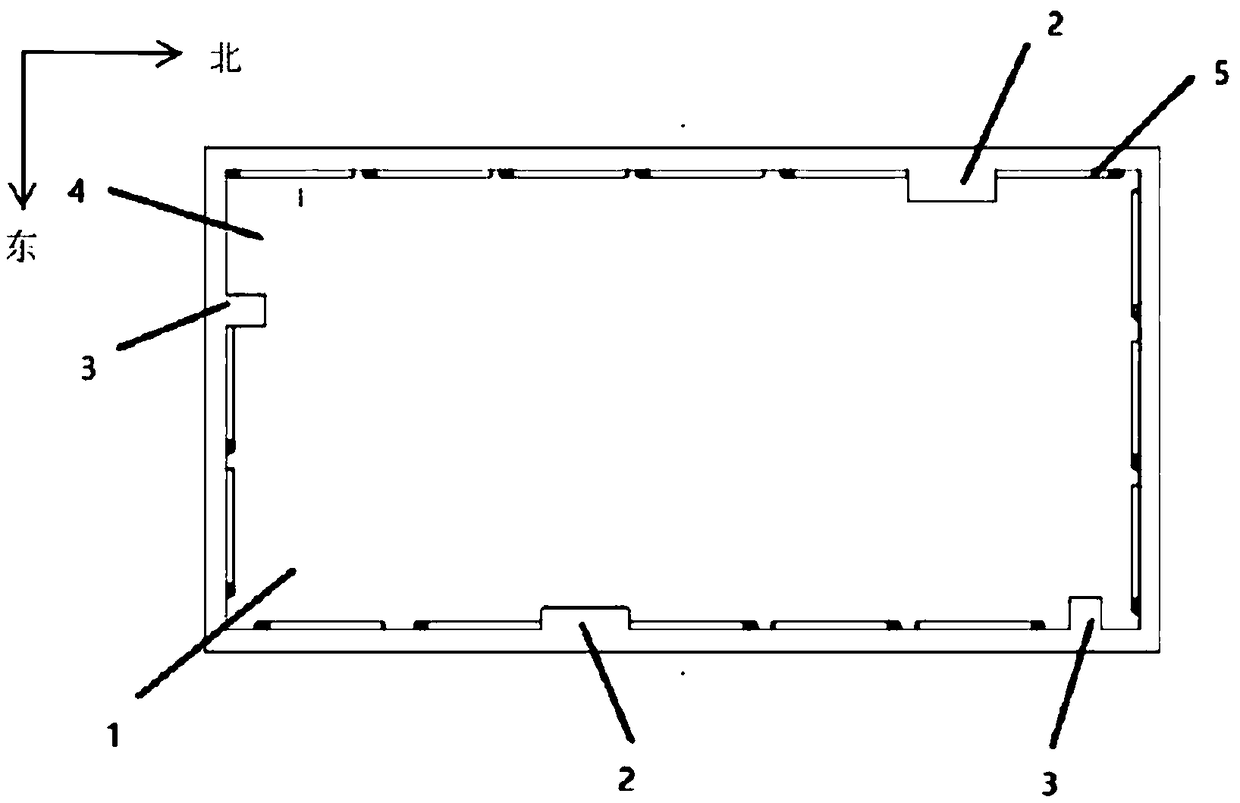

[0026] Such as figure 1 As shown, the passive cooling separated heat pipe arrangement structure in the spent fuel pool provided by an embodiment of the present invention, the separated heat pipe is mainly composed of the evaporation heat pipe 5, the condensation pipe 7 and the connecting pipe 8, and the evaporation heat pipe is arranged in the spent fuel pool 1. Below the level, it is necessary to avoid the area of gate 2 and return pipe 3 at the same time. Considering that the heat load of the spent fuel pool is 5MW, the number of evaporation heat pipes required is 208, and the number of condenser pipes is 640.

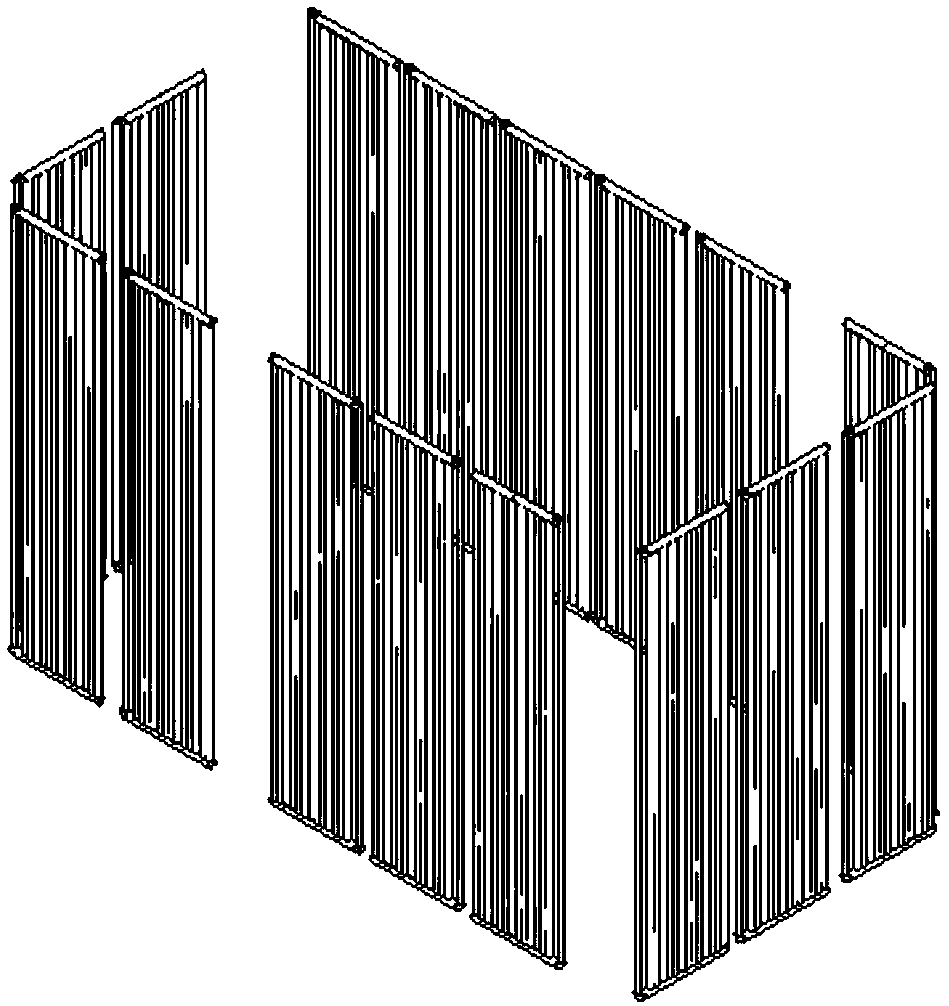

[0027] Such as figure 2 , image 3 As shown, the evaporating heat pipes are 13 assemblies arranged in a single r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com