Characteristic parameter test system and working process of laser beam long-distance transmission

A technology of long-distance transmission and characteristic parameters, which is applied in the direction of optical instrument testing, machine/structural component testing, instruments, etc. It can solve problems such as long-distance and long-term, and achieve stable movement and home, enhanced operability, and low cost. Effects of short key and eccentricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

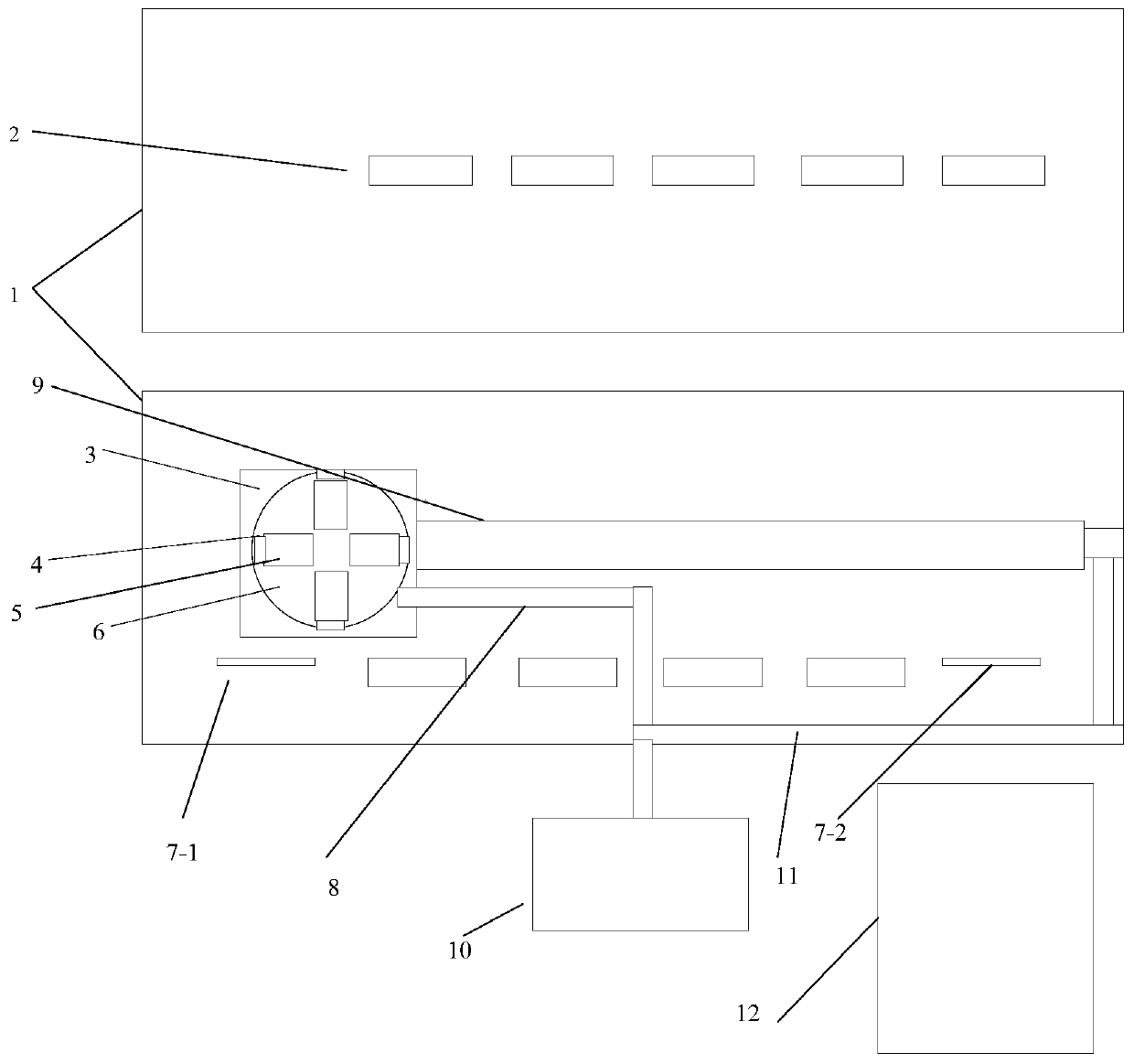

[0070] A laser with a wavelength of 632.8nm and a power of 2mW is incident on the light source, and the laser is used to actually measure the spectral spot:

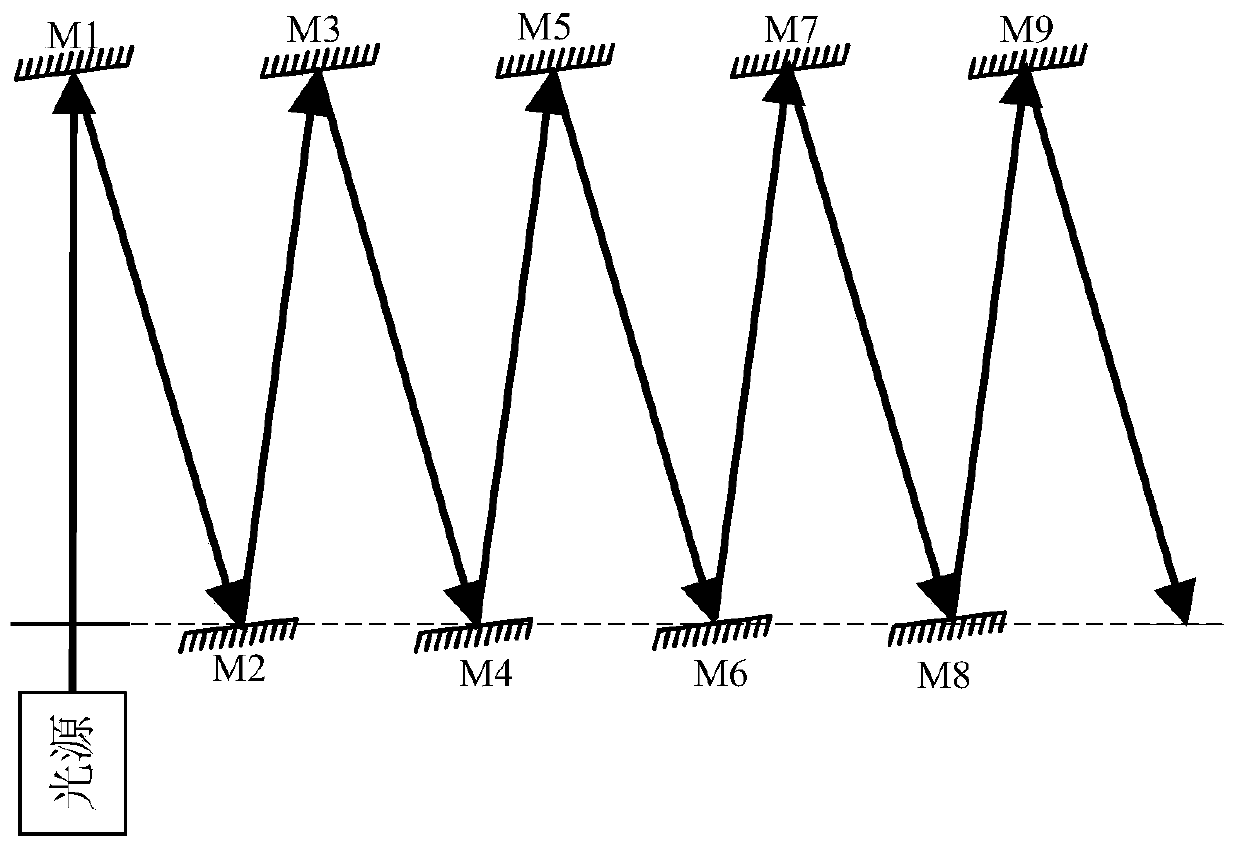

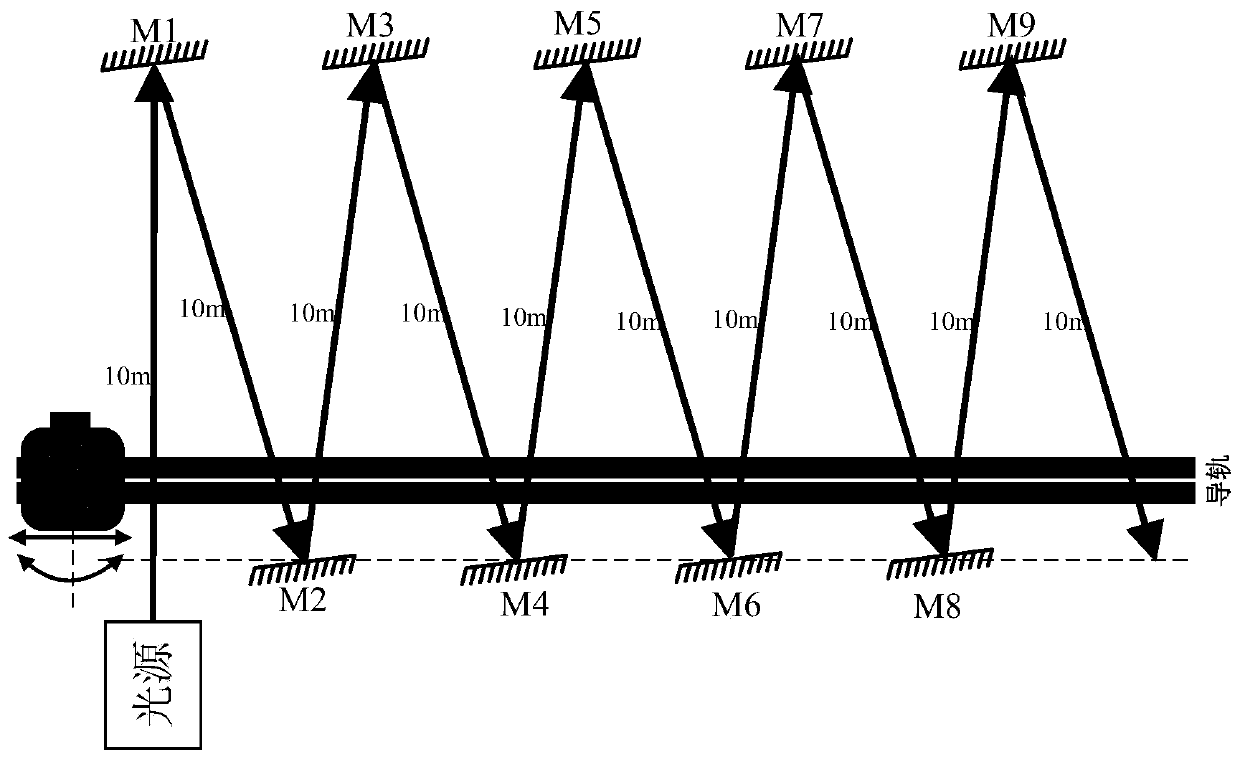

[0071] (1) Adjust the table top of the optical table to ensure that the surface of the optical table meets the required accuracy, install mirrors on the optical tables on both sides, pay attention to keep the height of the mirrors consistent, and place a crosshair in the center of the mirror.

[0072] (2) Install the optical translation guide rail, and install the electric rotary table on the translation table. During the installation process, ensure that the table is horizontal during the translation and rotation process. Start the electric translation platform to make the electric translation platform start to move. Take 6 points on the entire stroke. If the offset of the crosshair at these 6 points has a linear relationship with the displacement, the linear guide has been adjusted.

[0073] (3) Install the laser on th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com