A biomass hot water boiler equipment for recovering waste heat

A hot water boiler, biomass technology, applied in lighting and heating equipment, combustion equipment, water heaters and other directions, can solve the problems of large biomass fuel consumption, low boiler heat exchange efficiency, heat energy waste, etc., to achieve heat exchange efficiency High, low energy consumption, good combustion characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to further understand the content of the invention, features and effects of the present invention, the following examples are given in detail as follows:

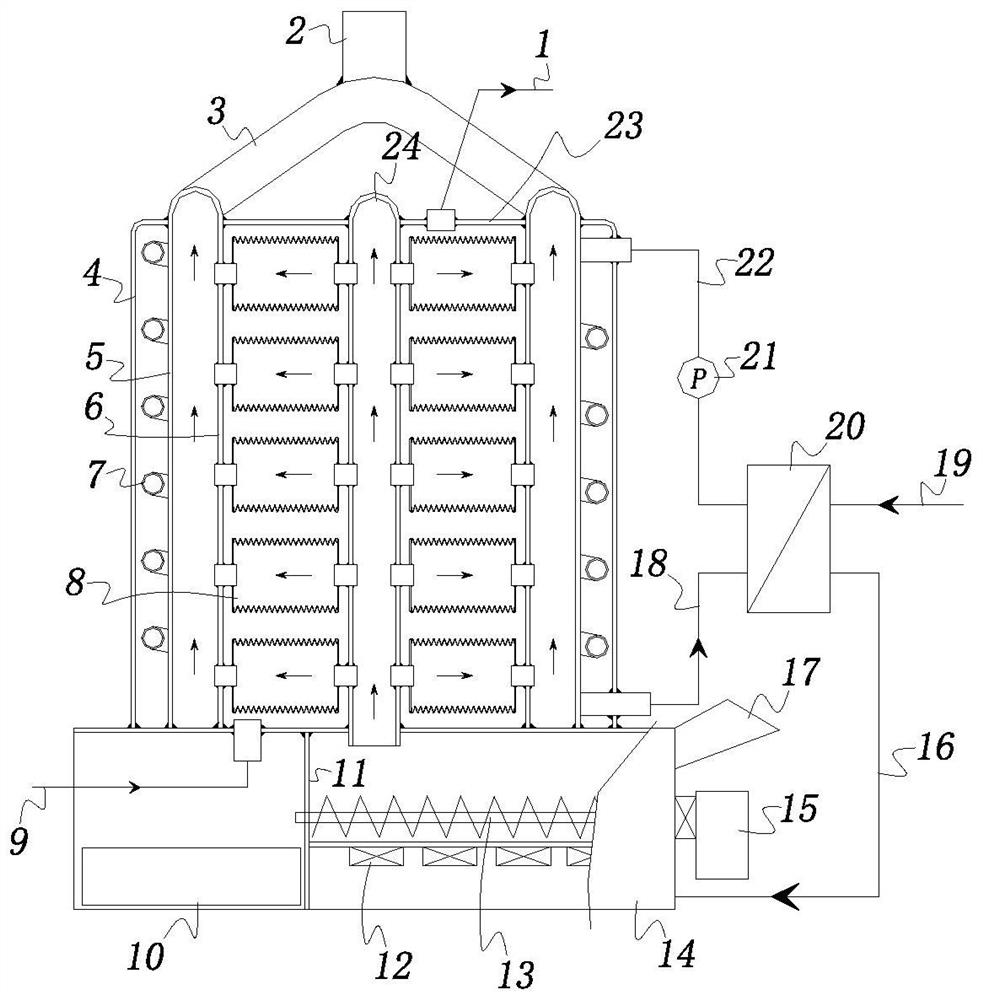

[0015] See figure 1 , the biomass hot water boiler equipment for recovering waste heat of the present invention includes a base, a water exchange tank device is arranged on the top of the base, and devices such as burners are mainly installed in the base, and the hot air flow obtained after combustion is heated in the water exchange tank. The device exchanges heat with water to heat it up.

[0016] The base includes a box body 14, the head end of the box body 14 is sealed, and the end is open. In the middle of the inner cavity of the box body 14, a partition 11 with an ash discharge port in the middle is provided, and the inner cavity is divided into a combustion chamber and an ash collection chamber. room. In the middle of the combustion chamber, a plurality of burners 12 are installed through brackets. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com