Compressor driver and compressor

A compressor and drive technology, applied in the field of compressors, can solve the problems of short stroke, large vibration of the crank-connecting rod mechanism, high center of gravity of the machine, etc., to reduce radial friction, improve dynamic transmission efficiency, and reduce energy consumption of the whole machine Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing.

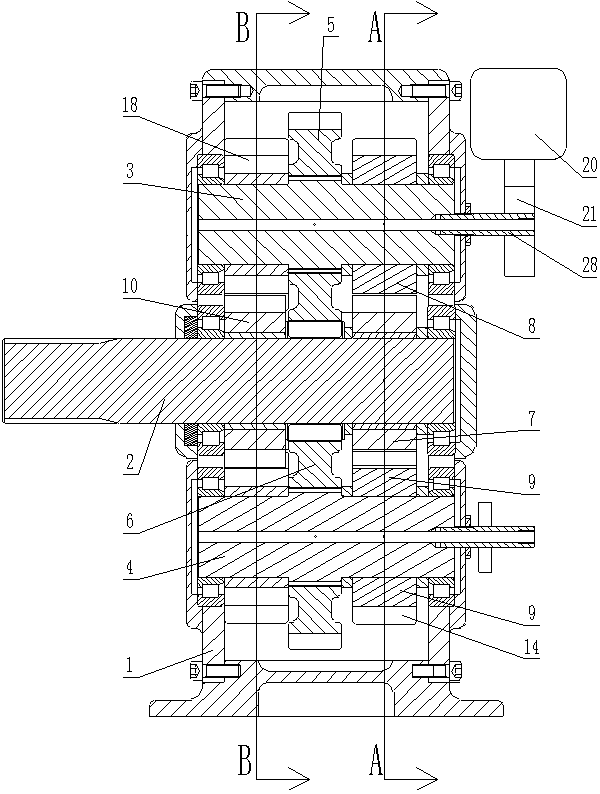

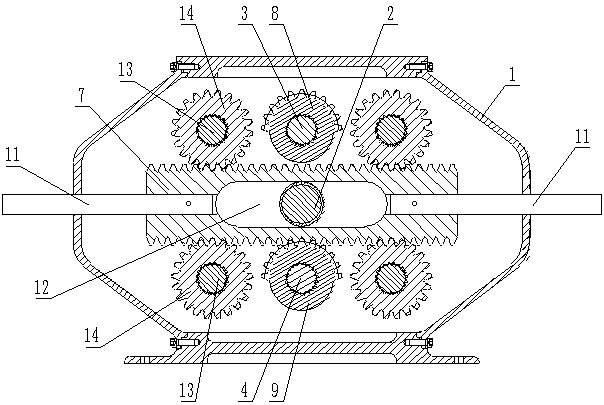

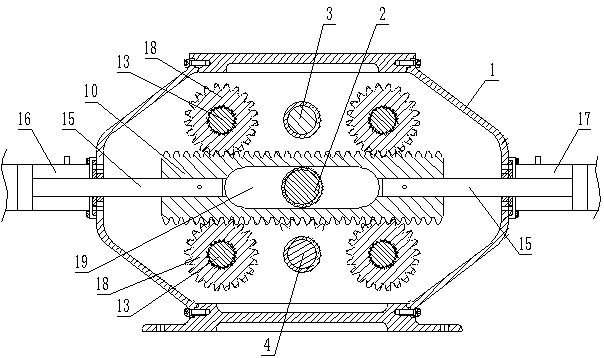

[0027] Such as Figure 1 to Figure 5 A compressor driver shown includes a housing 1 and an input shaft 2 rotatably mounted on the housing 1. The housing 1 is provided with an output rack 7 and a transmission member connected to the output rack 7. The input shaft 2 and the output rack 7 is provided with an incomplete rack and pinion mechanism for converting the rotary motion of the input shaft 2 into the reciprocating linear motion of the output rack 7, and the output rack 7 is fixedly connected with a The output shaft 11 extending in the direction of linear motion, the two ends of the output rack 7 are respectively provided with an output shaft 11, and the two output shafts 11 protrude outward from the housing 1, and also include a reciprocating linear motion that can drive the transmission part The hydraulic system can use the hydraulic system to provide thrust for the tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com