A ball throwing machine system and its control method

A ball machine and control module technology, applied in the direction of program control, electrical program control, general control system, etc., can solve problems such as inability to obtain entertainment effects, inconvenience for players to use, increase in entertainment costs, etc., to prolong life, ensure stirring effect, The effect of reducing motor loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

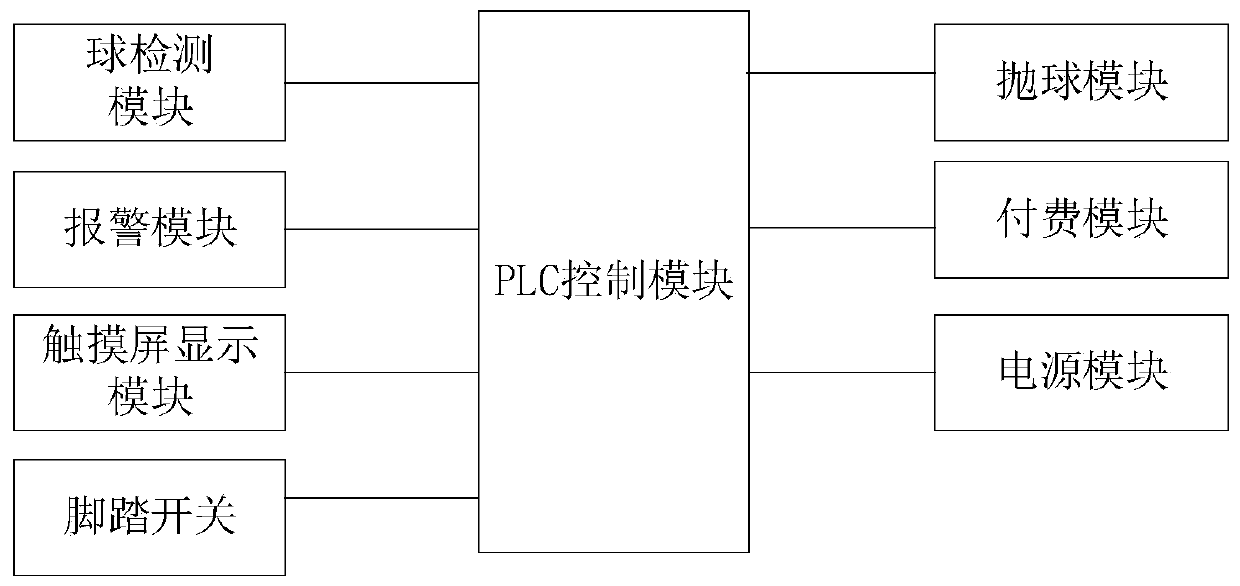

[0040] A ball throwing machine system such as Figure 1-6 As shown, it includes a touch screen display module, a PLC control module, a ball detection module, an alarm module, a ball throwing module, a payment module, a power supply module and a foot switch; the PLC control module is respectively connected to a touch screen display module, a ball detection module, and an alarm module , a throwing module, a payment module and a foot switch, the power module supplies power for a touch screen display module, a PLC control module, a ball detection module, an alarm module, a throwing module, a payment module and a foot switch;

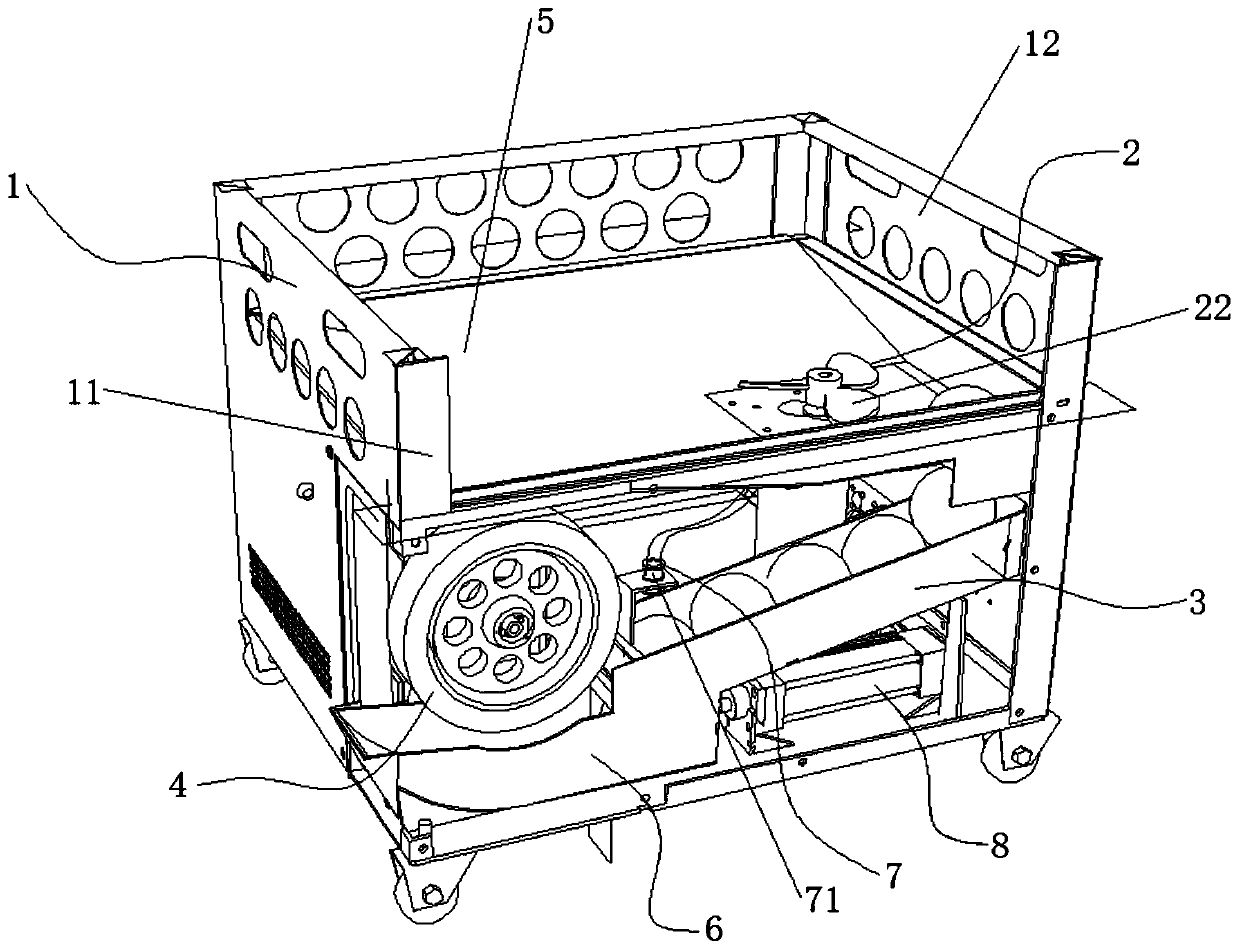

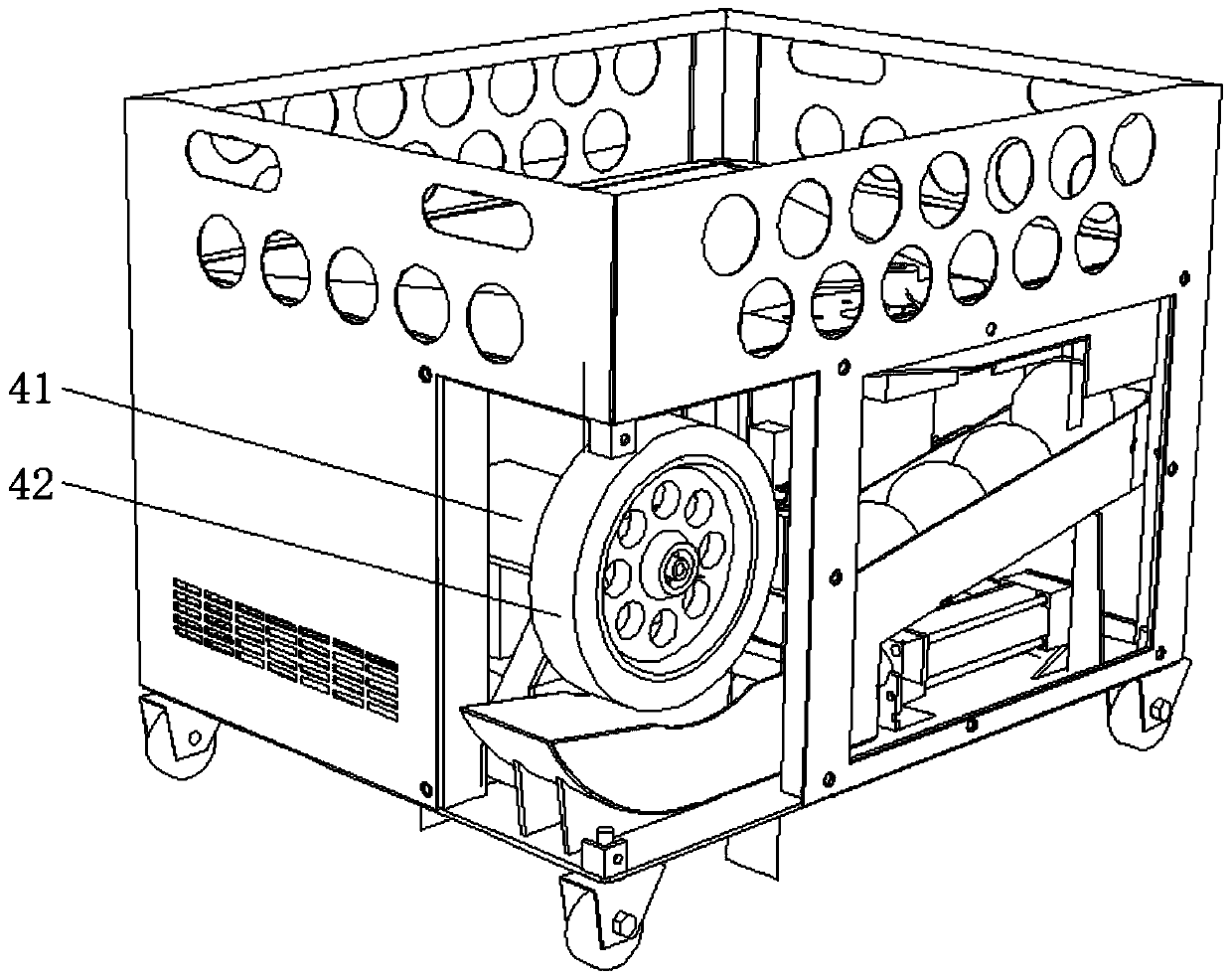

[0041] The ball throwing module includes an equipment frame 1, a mechanical stirring module 2, a transmission module 3, a serving module 4, a ball storage tank 5, a ball throwing arc groove 6, a pneumatic stirring module 7 and a cylinder pushing device 8; the equipment frame 1 The top is provided with a ball storage tank 5, and a group of mechanical stirring...

specific Embodiment approach 2

[0055] The difference from the first embodiment is that, if Figure 7 As shown, in this specific embodiment, the cylinder propulsion device 8 includes a set of drive motors 82, the main shaft of the drive motors 82 is fixedly connected with a set of drive screw screws 83, and a set of drive screw screws 83 is provided on the drive screw screws. The ball screw nut matched with the rod 83, the outer end sleeve of the ball screw nut is provided with a group of moving slides 85, and the moving slides are connected with a set of moving optical axes 84 through connecting pieces, and the moving optical axes are also provided with In a group of bearings, the bearings are set inside the equipment frame through a fixed frame, and the driving motor drives the screw to rotate, and then drives the ball screw nut and the moving slide to move linearly, and finally drives the moving optical axis to move in the bearing Inner rectilinear movement, fixing the push plate at the end of the moving ...

specific Embodiment approach 3

[0060] A control method based on the realization of the ball throwing machine system, such as Figure 8 shown, including the following steps:

[0061] Step a, turn on the power;

[0062] Step b, display the welcome interface and parameter settings through the touch screen display module, the parameters include the rotating speed of the ball, cylinder time and alarm time;

[0063] Step c, the touch screen display module transmits the information of parameter setting to the PLC control module, the PLC control module starts the PLC program operation, starts the ball detection module to collect and transmit the quantity of balls in the ball groove 31 in real time, and transmits the quantity information to the PLC control module, and the PLC The control module judges whether there is a sufficient number of balls, if the quantity is sufficient, proceed to step e, if the quantity is insufficient, proceed to step d;

[0064] Step d, the PLC control module controls the alarm module t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com