Novel gas well mouth tube type circulating rotation flow dewatering device

A cyclone dehydration, gas well technology, applied in wellbore/well components, production fluid, combustible gas purification, etc., can solve the problems of large diameter of gas-liquid separator equipment, strict inlet flow rate requirements, and high liquid content in gas gathering pipelines. , to achieve the effect of improving the effective separation efficiency of gas-liquid two-phase, improving gas-liquid two-phase separation efficiency, and improving gas-liquid separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

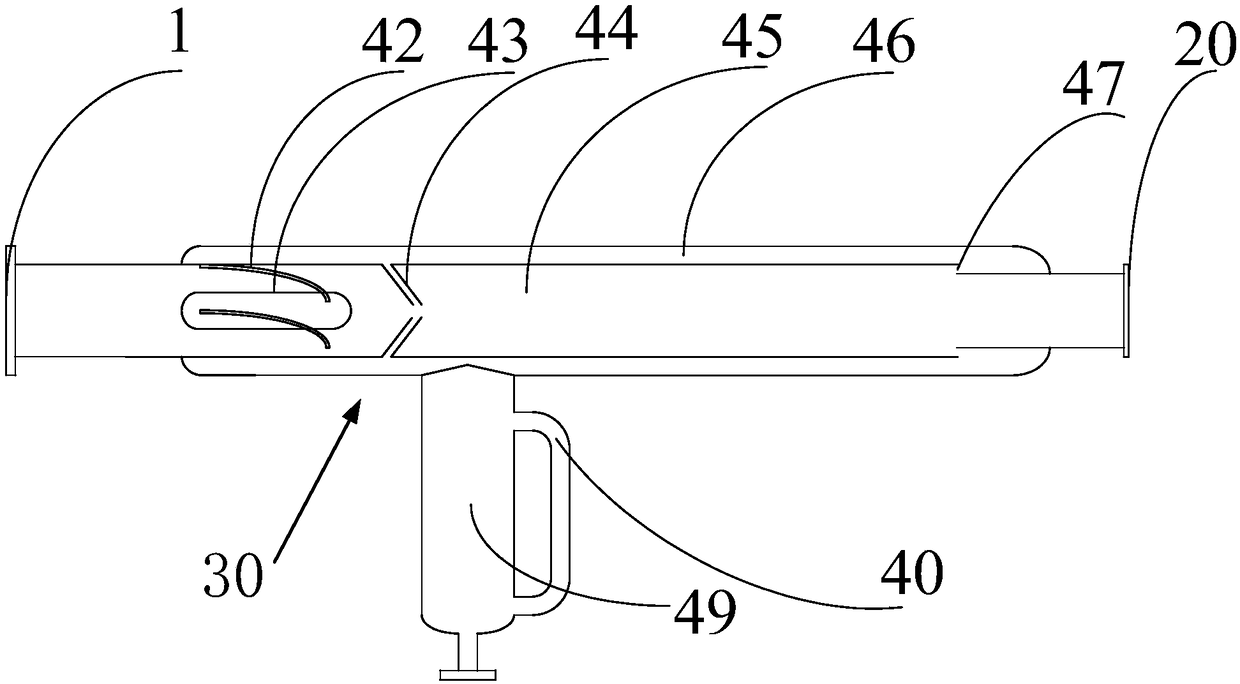

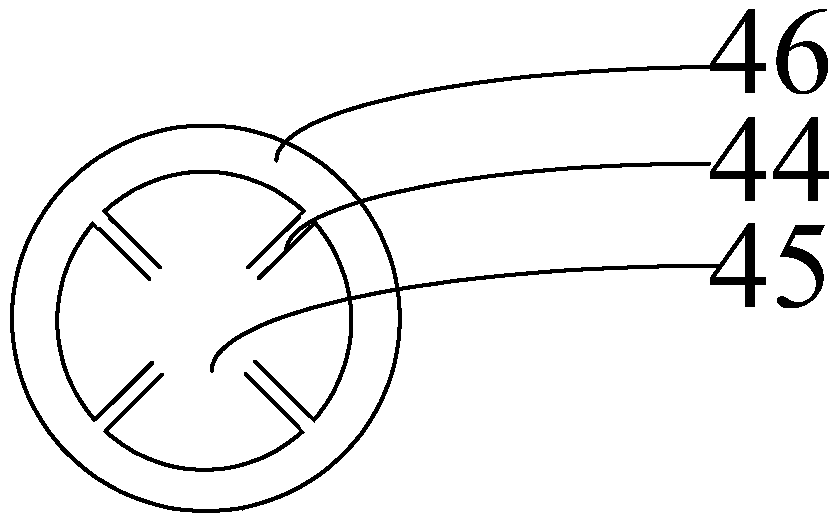

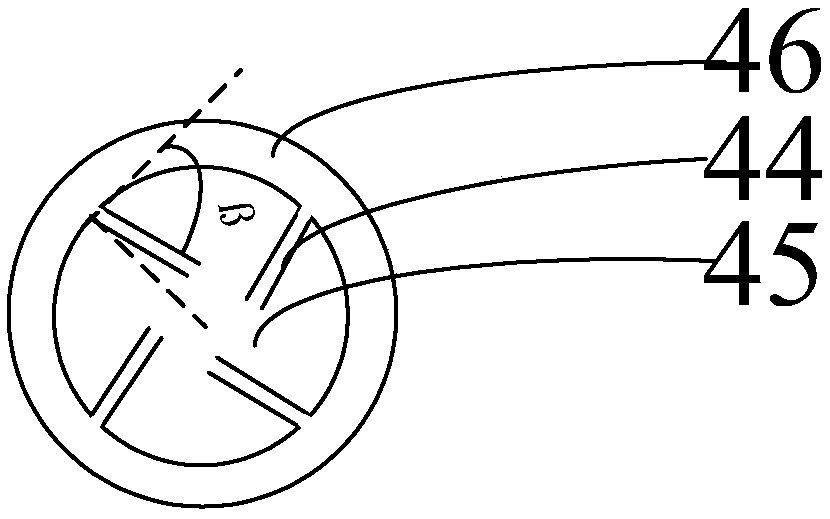

[0058] Embodiment one, such as Figures 1 to 4 As shown, the inner circulation cyclone dehydration assembly includes: a separation chamber 45 and an axial flow guide mechanism 42, and the axial flow guide mechanism 42 is attached to the axial flow guide shaft 43 on one side, and is sealingly connected with the attachment point of the axial flow guide shaft 43 , the other side of the axial guide mechanism 42 is attached to the inner wall of the separation chamber 45, and is in sealing connection with the attachment of the inner wall of the separation chamber 45. The end of the axial guide shaft 43 is provided with a hemispherical structure, and the hemispherical structure extends into the separation chamber. chamber 45, the outer layer of the separation chamber 45 is provided with a secondary separation diversion chamber 46; a first annular gap 47 is set between the separation chamber 45 and the secondary separation diversion chamber 46; the separation chamber 45 and the seconda...

Embodiment 2

[0064] Embodiment two: if Figures 5 to 11As shown, the internal circulation cyclone dehydration assembly includes: a primary internal circulation cyclone dehydration mechanism 50 and a secondary internal circulation cyclone dehydration mechanism 60; the input side of the primary internal circulation cyclone dehydration mechanism 50 and the cylindrical body 30 inlet Connected, the output side of the first-level internal circulation swirl dehydration mechanism 50 is connected with the input side of the second-level internal circulation swirl dehydration mechanism 60, and the output side of the second-level internal circulation swirl dehydration mechanism 60 is connected with the outlet 20 of the cylindrical body 30; The inner circulation cyclone dehydration mechanism 50 includes: a primary separation chamber 55 and a primary axial flow guide mechanism 52, the primary axial flow guide mechanism 52 is attached to the primary axial flow guide shaft 53 on one side, and is connected ...

Embodiment 3

[0076] Embodiment three: as Figures 12 to 16 As shown, the internal circulation cyclone dehydration assembly includes: four internal circulation cyclone dehydration mechanisms and a partition 18, the first end of the partition 18 and the inlet side of the cylindrical body 30 form the inlet chamber 2; the first end of the partition 18 The end and the outlet side of the cylindrical body 30 form an outlet chamber 9; the partition 18 evenly isolates the interior of the internal circulation cyclone dehydration assembly into four areas; each area is provided with an internal circulation cyclone dehydration mechanism 19.

[0077] In this embodiment, the internal circulation cyclone dehydration mechanism includes: a parallel secondary separation diversion chamber 6, a parallel separation chamber 7 and a parallel axial diversion mechanism 3; the parallel secondary separation diversion chamber 6 is attached to the cylindrical body 30 The inner wall is set, and the parallel secondary se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com