An integrated construction method and equipment for a cable-supported grid structure cable system traction and tension

A technology of grid structure and construction method, which is applied to the processing of building components, building structures, and building materials. The effect of controllable construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

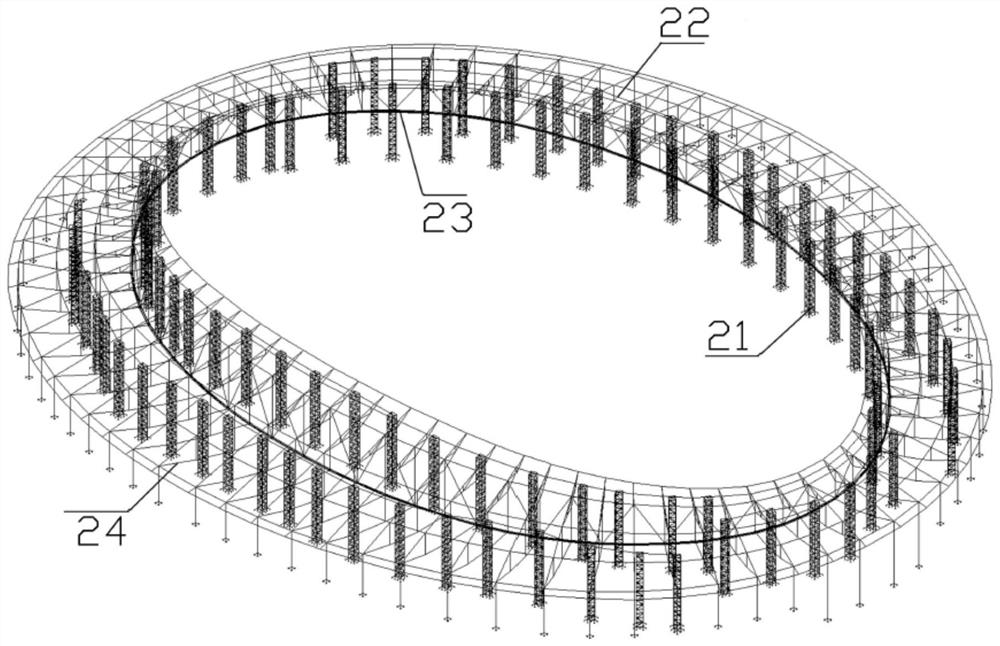

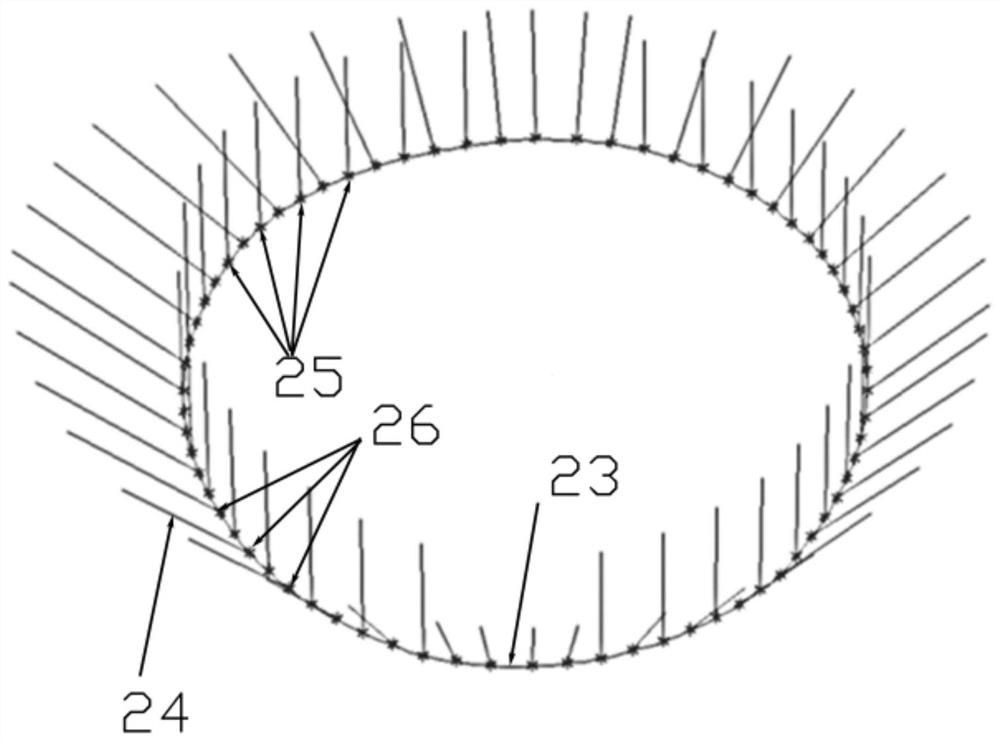

[0032] Embodiment 1 of the present invention provides an integrated construction method for cable traction and tensioning of a cable-supported grid structure, such as Figure 1-Figure 3 shown. in, figure 1 A three-dimensional perspective view of a stadium to which the invention is applicable is shown. The cable grid structure includes a support frame 21 arranged in a ring, a roof grid structure 22 arranged on the upper part of the support frame 21 , and a cable structure arranged below the roof grid structure 22 . Preferably, the support frame 21 is a steel structure support frame. Among them, the cable structure includes hoop cables 23 and radial cables 24 connected with the hoop cables 23. After the support frame 21 and the roof grid structure 22 are installed, all the cable structures are assembled on the ground. , and then carry out traction tension forming construction on all the assembled cable structures, wherein, the construction method also includes the following s...

Embodiment 2

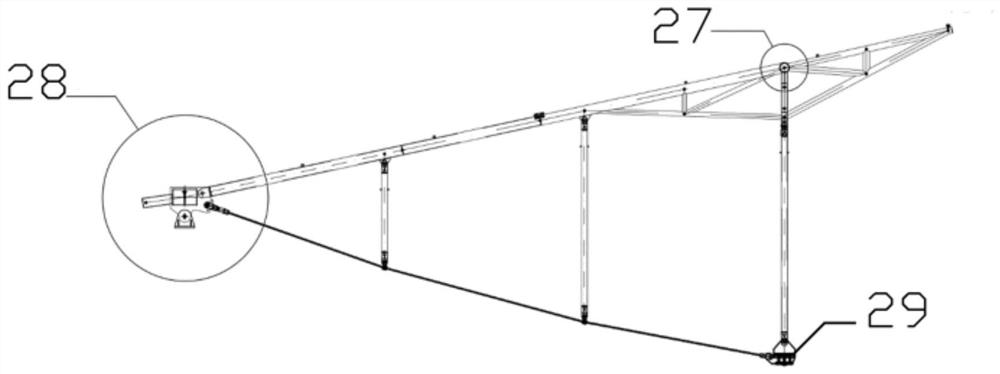

[0041] Embodiment 2 of the present invention provides an integrated equipment for cable traction and tension with a cable-supported grid structure, such as Figure 4 as shown, figure 1 It shows a structural schematic diagram of the integrated equipment for cable traction and tension of the cable-supported grid structure of the present invention. The integrated equipment of the present invention at least includes a tooling cable 19, a traction fixture 11 for fixing the tooling cable 19, and a lifting and pulling device 15 arranged at one end of the tooling cable 19 away from the traction fixture 11, wherein the traction fixture 11 can Be fixed to vertical traction fixed force point 27 and oblique traction fixed force point 28.

[0042] Wherein, the towed rope 12 is arranged between at least two tooling ropes 19, and is connected with the hoisting traction device 15, and the hoisting traction device 15 is connected with the hydraulic pump station 17 to provide power, and the hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com