3D printing production line and UV decorative sheet produced by production line

A 3D printing and 3D printer technology, which is applied in lamination devices, layered products, chemical instruments and methods, etc., can solve the problems of low production efficiency, high cost of decorative panels, and inability to promote large-scale promotion, and achieve consistent performance and structure Dense, high hardness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to make the objectives, technical solutions and advantages of the present invention clearer, the technical solutions of the present invention will be described in detail below. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments. Based on the embodiments of the present invention, all other implementations obtained by a person of ordinary skill in the art without creative work shall fall within the protection scope of the present invention.

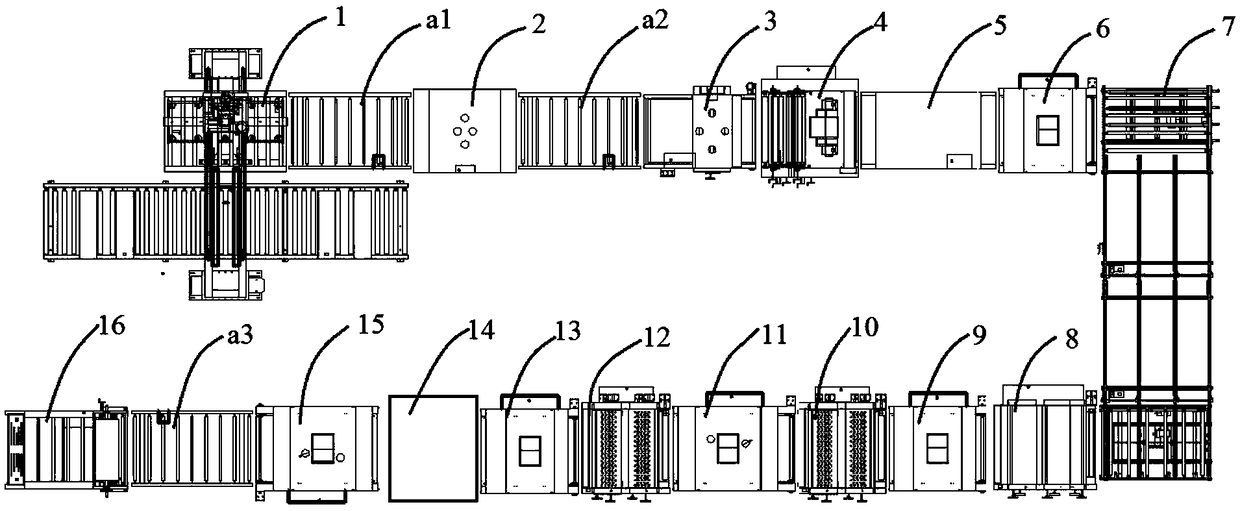

[0045] The embodiment of the present invention relates to a 3D printing pipeline, such as figure 1 As shown, it includes the following devices connected in sequence:

[0046] Back paint machine 4, first UV curing machine 5, putty machine 8, second UV curing machine 9, forward and backward roll coating machine 10, third UV curing machine 11, double roll coating machine 12, fourth UV curing machine 13. The 3D printer 14, the fifth UV curing machine 15, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com