Anti-falling safety well lid assembly

An anti-fall, manhole cover technology, applied in water conservancy projects, artificial islands, underwater structures, etc., can solve problems such as failure to alleviate the loss of manhole covers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

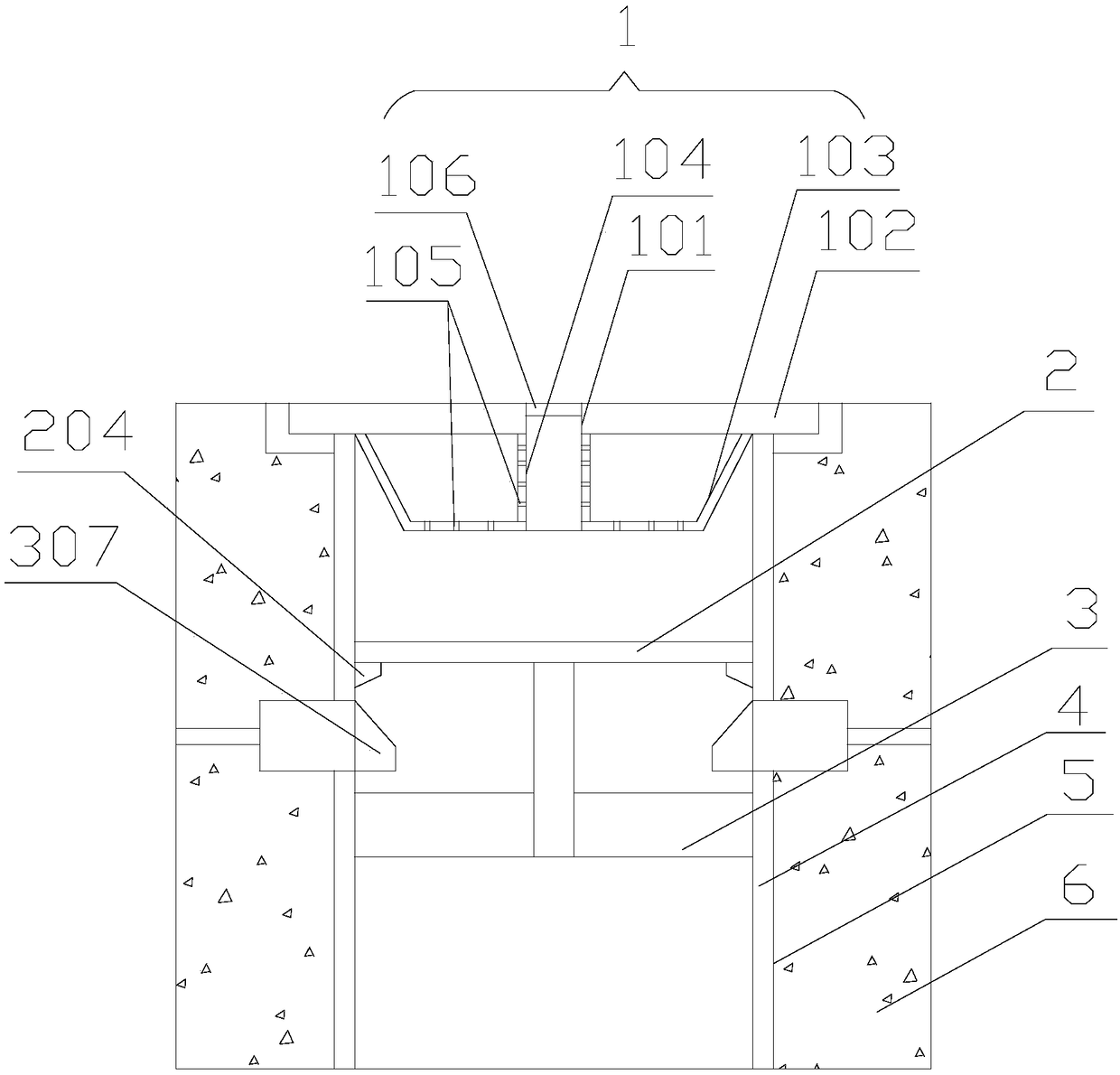

[0041] This embodiment provides an anti-fall safety well cover assembly, including a well cover 1 and an anti-fall screen 2. It includes a positioning cylinder 201, a plurality of radiating ribs 202 and a plurality of reinforcing ribs 203, and a plurality of radiating ribs 202 are uniformly distributed and fixed along the outer wall of the positioning cylinder 201 in a radial shape. The tube 201 is distributed on the coaxial center line to strengthen and fix the radial ribs 202, and a plurality of reinforcing ribs 203 are distributed at equal intervals along the radial direction of the positioning tube 201; the well cover 1 is provided with a through hole 101 for water circulation;

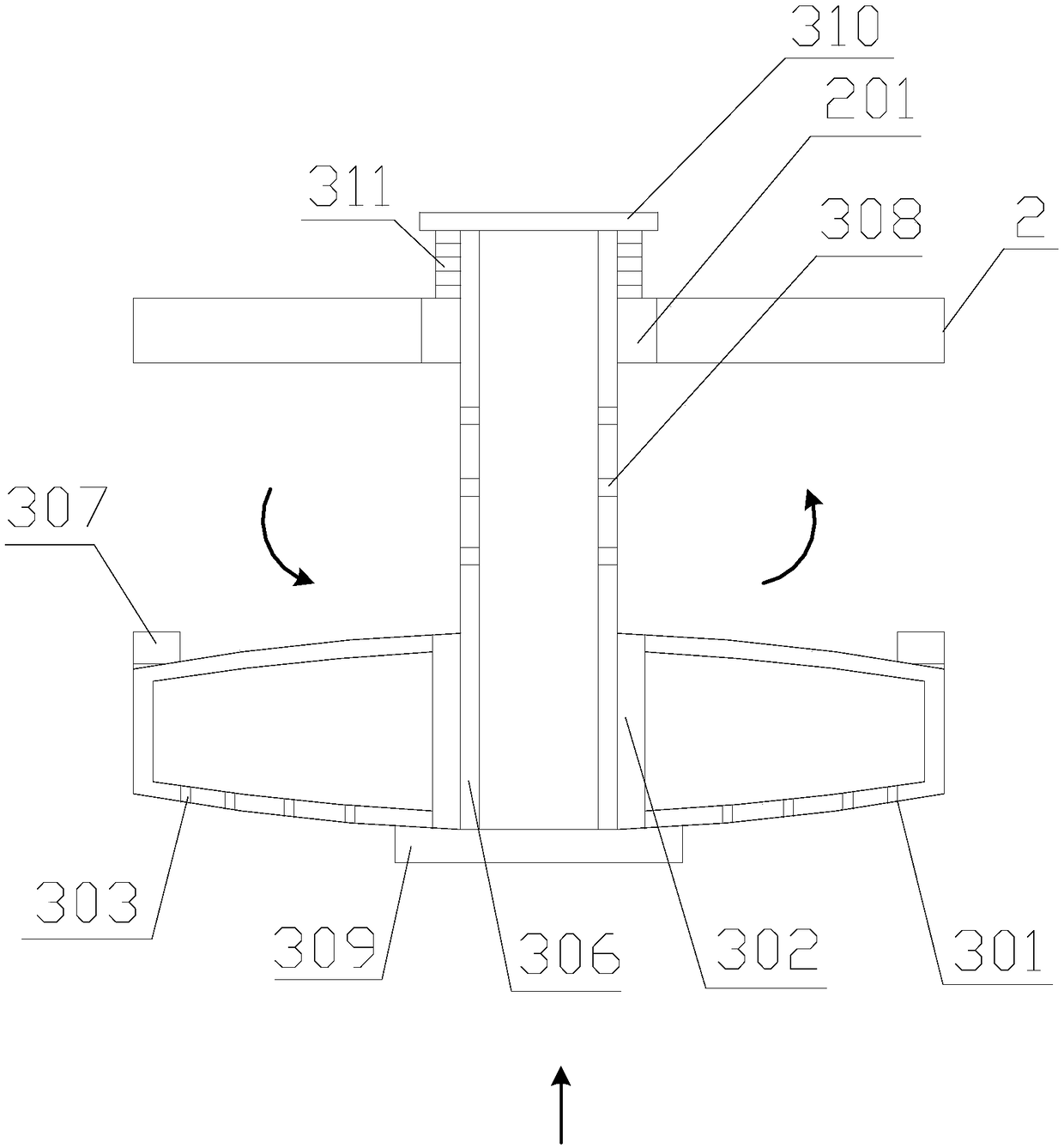

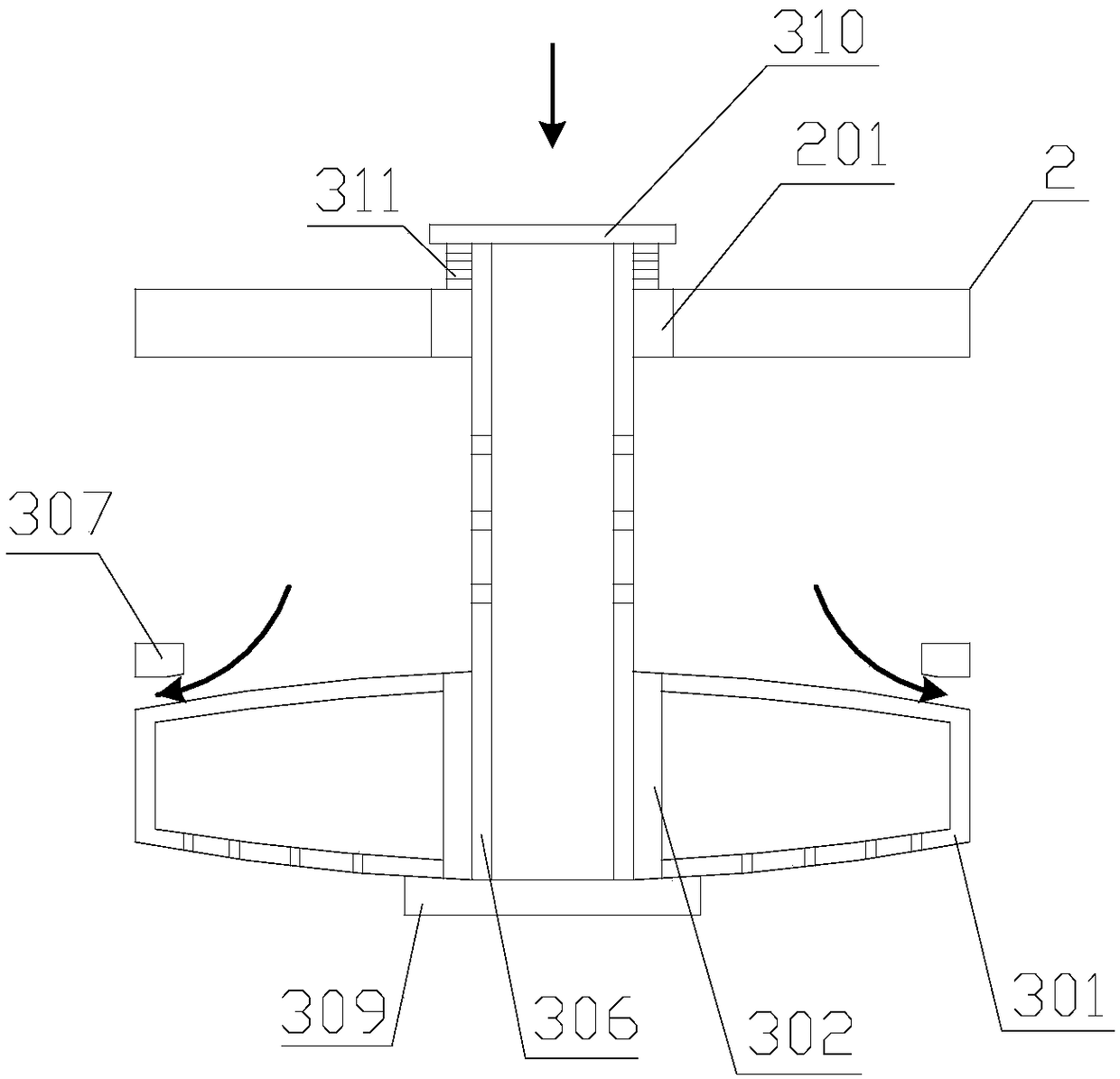

[0042] It also includes a buffer mechanism 3. The buffer mechanism 3 includes an outer sleeve 301, an inner sleeve 302, and a central tube 306. Both axial ports of the outer sleeve 301 are closed by sealing plates, and the inner sleeve 302 runs through the outer sleeve 301 in the axial direction. ...

Embodiment 2

[0044] Further improvement on the basis of Embodiment 1, the sealing plates at both axial ends of the outer sleeve 301 are curved plates protruding outward, and the axial section of the outer sleeve 301 has a spindle structure. A rubber strip is arranged on the surface of the first limiting ring 307 facing the outer sleeve 301 , and the first limiting ring 307 is in contact with the lower surface of the outer sleeve 301 through the rubber strip. The axial end of the central tube 306 provided with bearings runs through the inner sleeve 302, and the end of the central tube 306 passing through the inner sleeve 302 is provided with a first baffle 309, and the first baffle 309 faces the surface of the outer sleeve 301 The ring is provided with a rubber strip, and the contact between the first baffle plate 309 and the outer sleeve 301 is through the rubber strip.

Embodiment 3

[0046] Further improvement on the basis of Embodiment 2, the central tube 306 runs through the axial end of the positioning cylinder 201 and is provided with a second baffle 310, the outer diameter of the second baffle 310 is larger than the inner diameter of the positioning cylinder 201; the central tube 306 runs through the positioning cylinder A buffer spring 311 is sheathed on the pipe section after 201 , one axial end of the buffer spring 311 is fixed on the second baffle plate 310 , and the other axial end is fixed at the top port of the positioning cylinder 201 . The central tube 306 and the positioning cylinder 201 are in clearance fit; the inner wall of the positioning cylinder 201 is concavely provided with several positioning grooves 205, and the plurality of positioning grooves 205 are distributed at equal intervals along the circumferential direction of the positioning cylinder 201 inner wall, and the extending direction of each positioning groove 205 is the same as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com