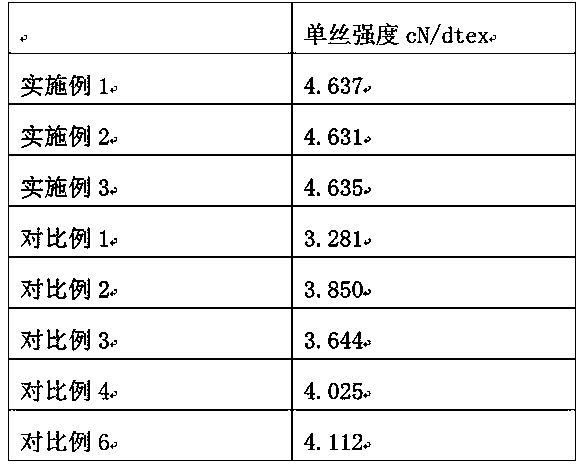

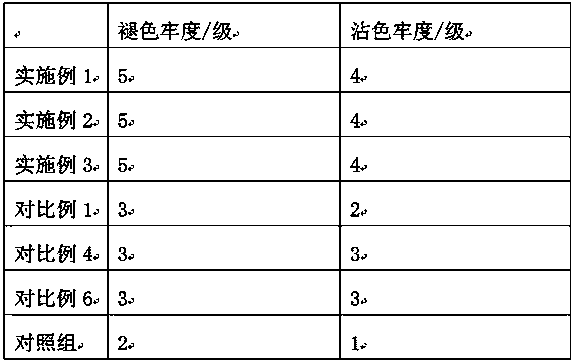

Nylon wig fibers with good dyeing performance

A technology for dyeing performance and wigs, applied in the field of wigs, can solve the problems of poor color fastness, wig fiber color, low dyeing rate, etc., and achieve the effects of dyeing quality assurance, improving adsorption, and improving comprehensive strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A nylon wig fiber with good dyeing performance, made of the following components by weight: tert-butylamine composite modified nylon slice 90, chlorinated polyethylene graft copolymer 4.5, hydroxyl silicone oil 1.8, 1,2-dimethyl Imidazole 0.13, nano diatomite 1, sodium stearate 3.1, plasticizer 2.1, graphene 1.8, calcium carbonate 12.

[0025] Further, the preparation method of the polyvinyl chloride graft copolymer is:

[0026] (1) Add 78 parts by weight of chlorinated polyethylene, 2.2 parts by weight of catalyst, and 310 parts by weight of solvent into the reactor, vacuumize and stir for 55 minutes;

[0027] (2) Add 6 parts by weight of octadecyl methacrylate, 1.3 parts by weight of isooctyl acrylate, 0.58 parts by weight of 2-chloroaniline, and 0.014 parts by weight of accelerator, heat to 75°C, and react for 3.5 hours , and then filter out the precipitate, wash with water, and dry to constant weight.

[0028] Further, the solvent is absolute ethanol.

[0029] Fu...

Embodiment 2

[0041] A nylon wig fiber with good dyeing performance, made of the following components by weight: tert-butylamine composite modified nylon slice 93, chlorinated polyethylene graft copolymer 6.2, hydroxyl silicone oil 2.2, 1,2-dimethyl Imidazole 0.15, nano diatomite 3, sodium stearate 3.4, plasticizer 2.5, graphene 2.3, calcium carbonate 18.

[0042] Further, the preparation method of the polyvinyl chloride graft copolymer is:

[0043] (1) Add 78 parts by weight of chlorinated polyethylene, 2.2 parts by weight of catalyst, and 310 parts by weight of solvent into the reactor, vacuumize and stir for 55 minutes;

[0044] (2) Add 6 parts by weight of octadecyl methacrylate, 1.3 parts by weight of isooctyl acrylate, 0.58 parts by weight of 2-chloroaniline, and 0.014 parts by weight of accelerator, heat to 75°C, and react for 3.5 hours , and then filter out the precipitate, wash with water, and dry to constant weight.

[0045] Further, the solvent is absolute ethanol.

[0046] Fu...

Embodiment 3

[0058] A nylon wig fiber with good dyeing performance, made of the following components by weight: tert-butylamine composite modified nylon slice 92, chlorinated polyethylene graft copolymer 4.6, hydroxyl silicone oil 1.9, 1,2-dimethyl Imidazole 0.14, nano diatomite 2, sodium stearate 3.3, plasticizer 2.4, graphene 1.9, calcium carbonate 15.

[0059] Further, the preparation method of the polyvinyl chloride graft copolymer is:

[0060] (1) Add 78 parts by weight of chlorinated polyethylene, 2.2 parts by weight of catalyst, and 310 parts by weight of solvent into the reactor, vacuumize and stir for 55 minutes;

[0061] (2) Add 6 parts by weight of octadecyl methacrylate, 1.3 parts by weight of isooctyl acrylate, 0.58 parts by weight of 2-chloroaniline, and 0.014 parts by weight of accelerator, heat to 75°C, and react for 3.5 hours , and then filter out the precipitate, wash with water, and dry to constant weight.

[0062] Further, the solvent is absolute ethanol.

[0063] Fu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com