Anode residue treatment process suitable for non-ferrous metal pyrometallurgy

A pyrometallurgical and non-ferrous metal technology, applied in the direction of improving process efficiency, can solve the problems of smoke pollution and lead vapor pollution that cannot be effectively controlled, continuous feeding cannot be carried out, and the feeding port is blocked, so as to shorten the smelting of residual poles. Time, smoke and dust collection effect is good, good collection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

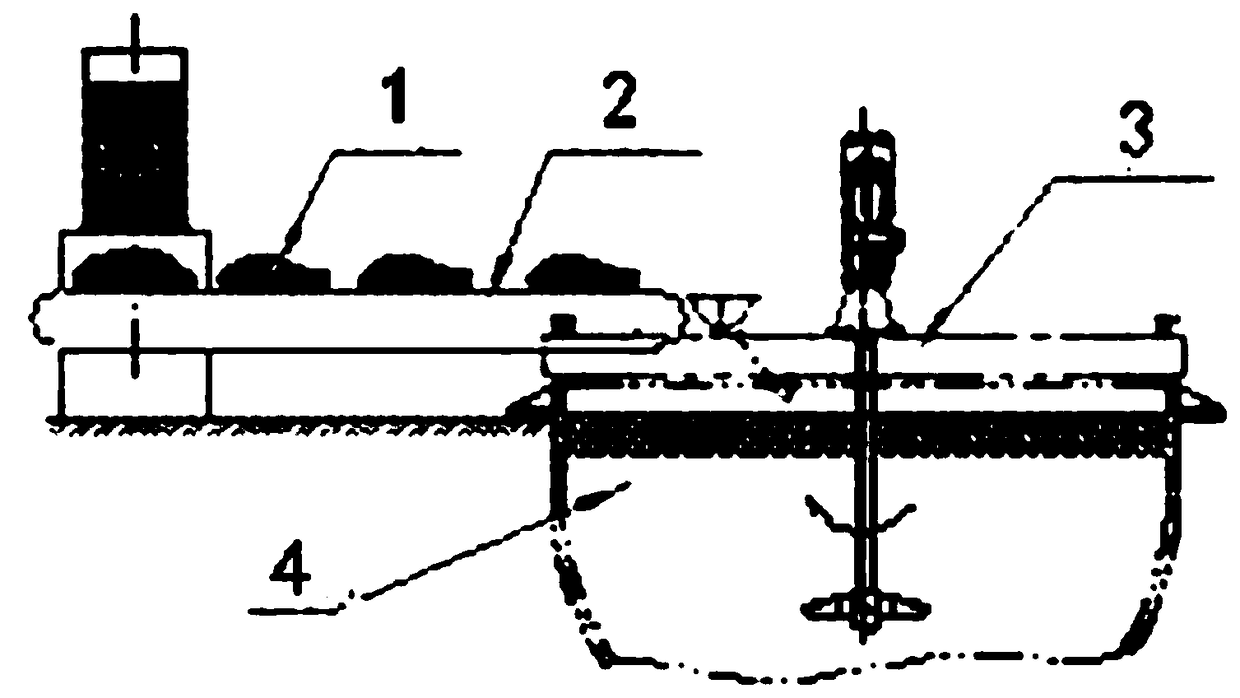

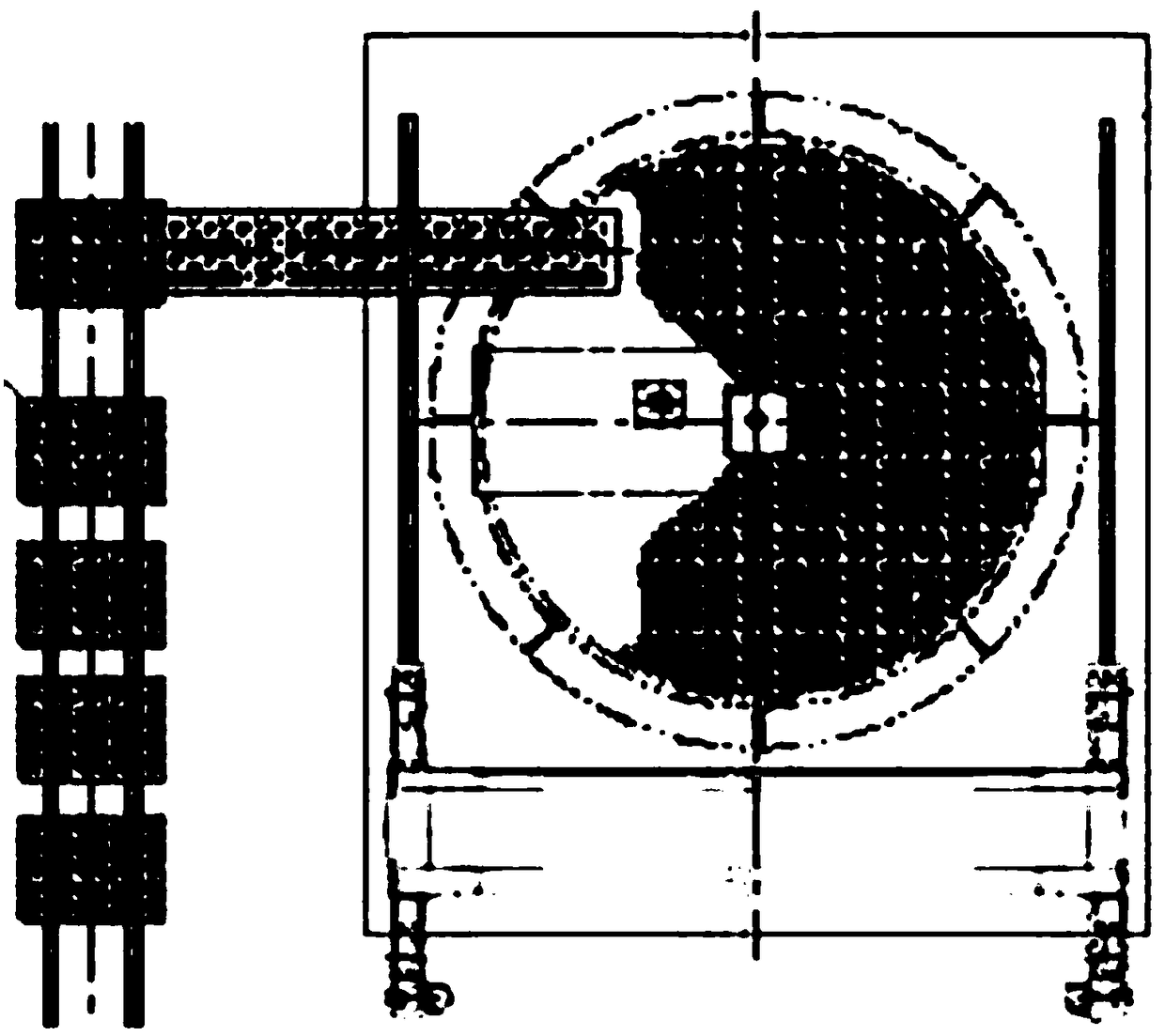

[0024] Embodiment 1, the present invention comprises the following steps: 1. Rinse the anode butt piece with clear water to remove the residual electrolyte on the anode butt piece; 2. Carry out block processing on the anode butt piece to greatly increase the surface area of the material , which can effectively speed up the melting time of the material, thereby shortening the process time and improving production efficiency; 3. Drying, removing the moisture on the surface of the anode butt block 1, greatly reducing the surface moisture of the material, and avoiding the popping sound when the anode residue is put in and lead liquid splashing, which is conducive to safe production; 4. Putting in, continuously throwing the anode residual block 1 into the recovery device to shorten the process time and improve production efficiency; The smelting device is returned to the furnace to make new plates to realize the recycling of resources and save resources; the above-mentioned steps ...

Embodiment 2

[0025] Embodiment 2, the present invention comprises the following steps: 1. Rinse the anode butt piece with clear water to remove the electrolyte remaining on the anode butt piece; 2. Carry out block processing to the anode butt piece to greatly increase the surface area of the material , which can effectively speed up the melting time of the material, thereby shortening the process time and improving production efficiency; 3. Drying, removing the moisture on the surface of the anode butt block 1, greatly reducing the surface moisture of the material, and avoiding the popping sound when the anode residue is put in and lead liquid splashing, which is conducive to safe production; 4. Putting in, continuously throwing the anode residual block 1 into the recovery device to shorten the process time and improve production efficiency; The smelting device is returned to the furnace to make new plates to realize the recycling of resources and save resources; the above-mentioned steps...

Embodiment 3

[0026]Embodiment 3, the present invention comprises the following steps: 1. Rinse the anode butt piece with clear water to remove the electrolyte remaining on the anode butt piece; 2. Carry out block processing on the anode butt piece to greatly increase the surface area of the material , which can effectively speed up the melting time of the material, thereby shortening the process time and improving production efficiency; 3. Drying, removing the surface moisture of the anode butt block 1, greatly reducing the surface moisture of the material, and avoiding the popping sound and noise when the anode is put in Lead liquid splashes, which is conducive to safe production; 4. Putting in, continuously throwing the anode butt pieces 1 into the recycling device to shorten the process time and improve production efficiency; The device is returned to the furnace to make a new plate to realize the recycling of resources and save resources; the conveying line 2 is used for material tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com