Fire guide device of coke oven ascending pipe as well as working method thereof

A coke oven and flame tube technology, which is used in the heating of coke ovens, the discharge device of dry distillation gas, and the coke ovens, etc., can solve the problems of heat deformation, escape and flame length of the dust cover, and achieve good ventilation and device structure. Simple and effective in improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

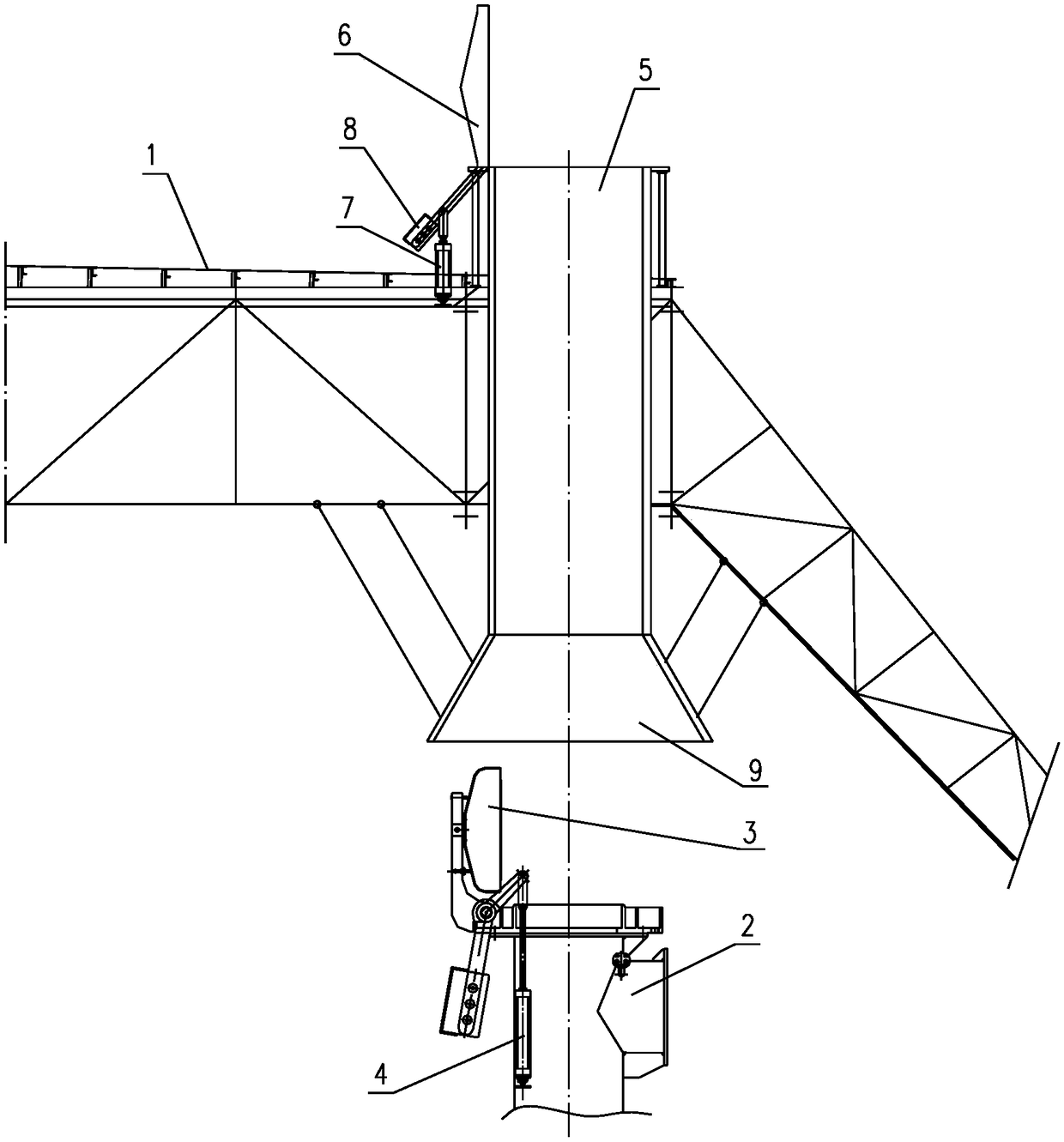

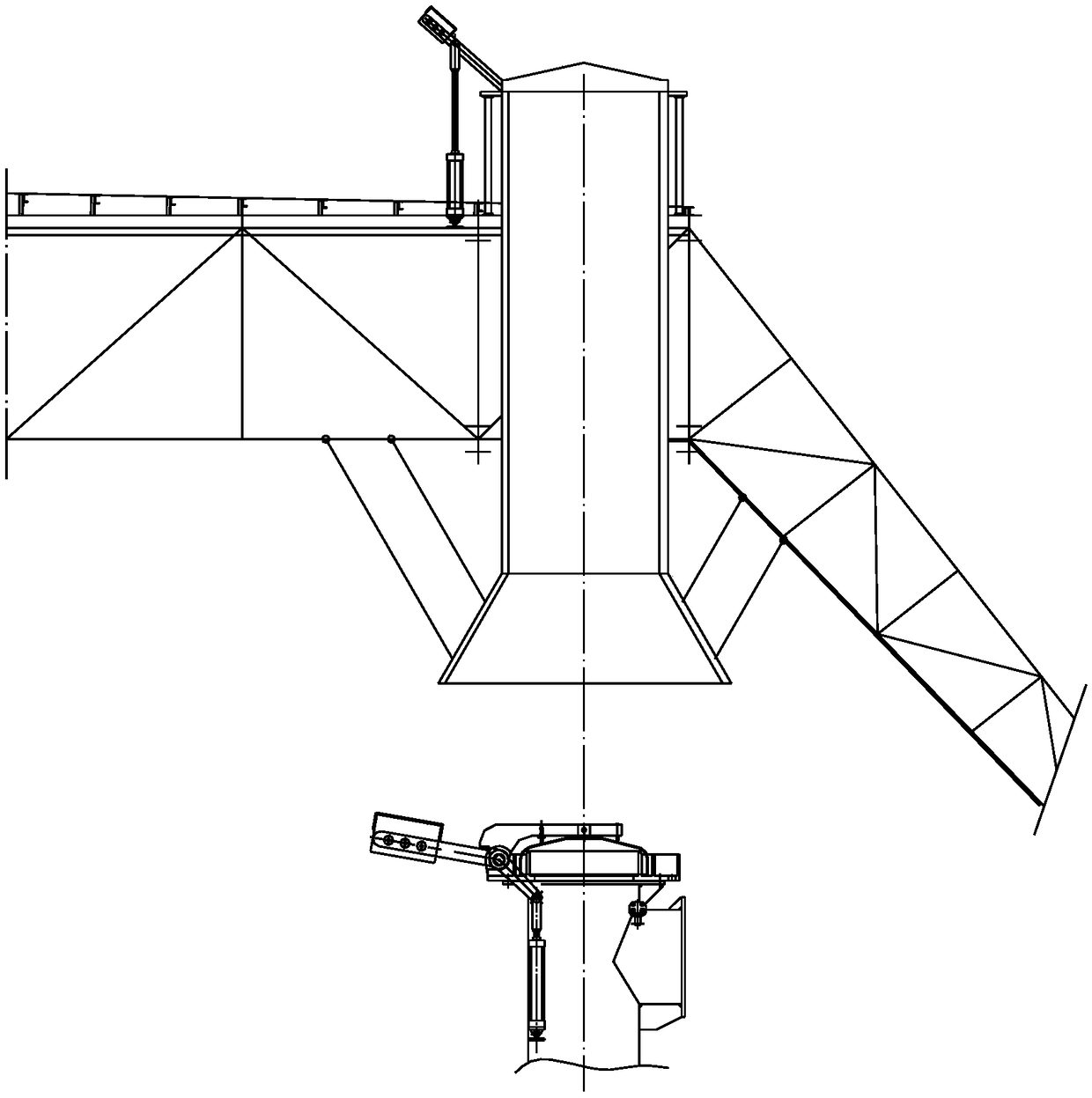

[0028] Such as figure 1 , figure 2 As shown, the ignition device of a coke oven riser according to the present invention, the coke oven riser is composed of a riser 2, a water seal cover 3, and a water seal actuator 4, and the top outlet of the riser 2 is located at the coke oven The bottom of the furnace dust removal cover 1 is provided with a water seal cover 3, and the water seal cover 3 is driven by the water seal cover actuator 4 to realize opening and closing; The pipe cover actuator 7 is composed of a fire pipe 5 arranged directly above the rising pipe 2, and the top of the fire pipe 5 passes outside the coke oven dust cover 1 and a fire pipe cover 6 is provided. The fire pipe cover 6 is formed by the fire pipe The fire tube cover actuator 7 is driven to realize opening and closing.

[0029] The water seal 3 is provided with a water sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com