Hydraulic drive system for forklift

A drive system, forklift technology, applied in the direction of fluid pressure actuators, brakes, vehicle components, etc., can solve the problems of low efficiency, complex hydraulic drive system, etc., and achieve the effect of light and comfortable operation, convenient operation and low failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

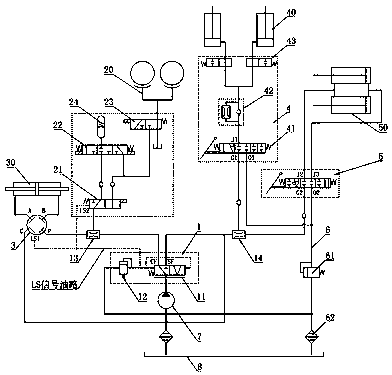

[0038] Such as figure 1 As shown, a hydraulic drive system for a forklift according to the present invention includes a braking device 20, a lifting cylinder 40, a tilting cylinder 50 and a steering cylinder 30, and the braking device 20, the lifting cylinder 40, and the tilting cylinder 50 and steering oil cylinder 30 provide high-pressure oil gear pump 7 and hydraulic oil tank 8; the drive system also includes oil inlet valve plate 1, brake oil circuit 2, steering oil circuit 3, lifting oil circuit 4, inclined oil circuit 5 and oil return line 6.

[0039] Specifically, a brief description of the above oil inlet valve plate 1, each functional oil circuit and oil return pipeline 6 is given as follows:

[0040] Oil inlet valve plate 1, which includes a priority valve 11, a safety valve 12, a first three-way flow limiting valve 13 and a second three-way flow limiting valve 14; the inlet of the priority valve 11 is connected to the outlet of the gear pump 7, and the hydraulic pr...

Embodiment 2

[0061] The structure of this embodiment 2 is the same as that of embodiment 1, and this embodiment 2 is to describe the brake oil circuit 2 in detail:

[0062] The brake system of the hydraulic drive system for forklifts in the second embodiment includes a brake device 20 and a brake oil circuit 2 . The brake device 20 is adapted to be hydraulically driven to brake the wheels of the forklift. refer to figure 1 As shown, the brake oil circuit 2 includes an accumulator 24, a first control valve 21, a second control valve 22, a third control valve 23, a first one-way valve and a second one-way valve.

[0063] Specifically, the first control valve 21 is respectively connected to the accumulator 24, the first three-way restrictor valve 13 and the braking device 20; the first control valve 21 is an electromagnetic reversing valve or a mechanical reversing valve, It can selectively output hydraulic oil to the accumulator 24 or the braking device 20 .

[0064] The first control val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com