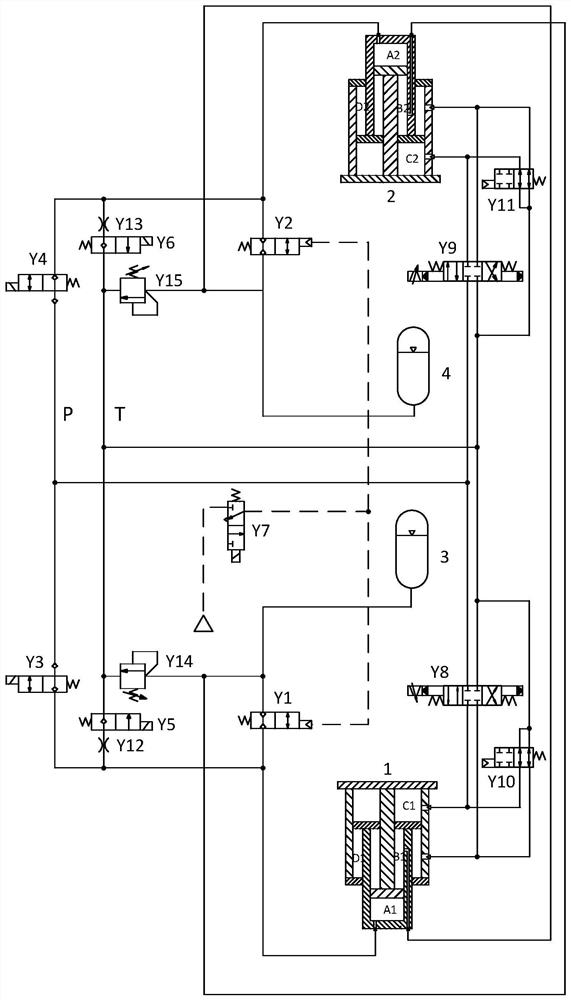

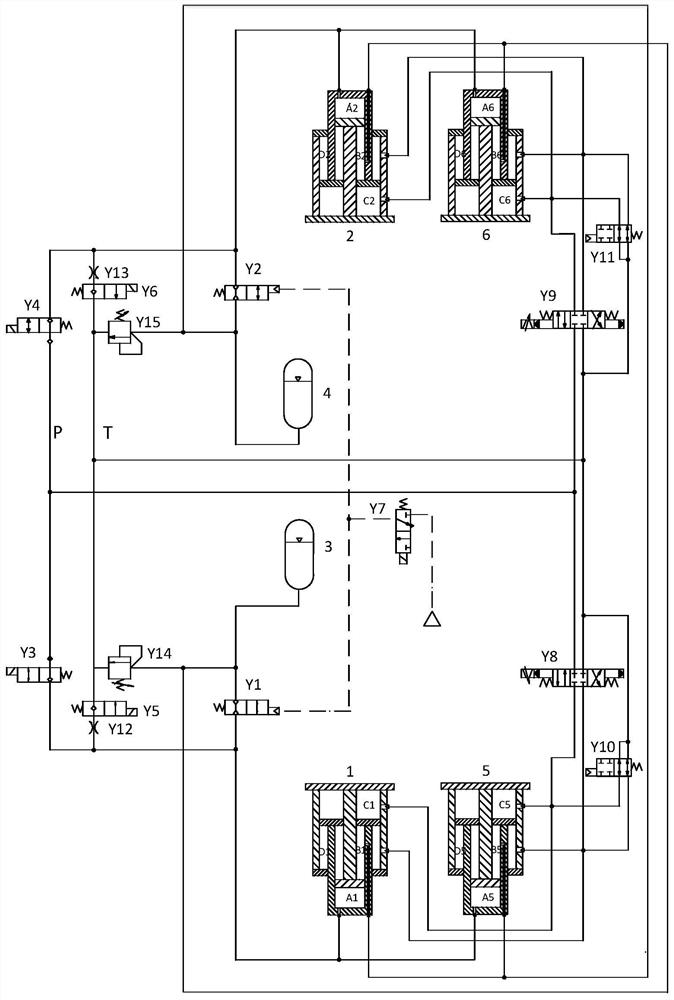

The switching control loop between the hydro-pneumatic suspension and the active suspension

A control loop and active suspension technology, which is applied to suspensions, elastic suspensions, vehicle components, etc., can solve the problems of non-adjustable accumulator pressure and difficulty in ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0024] exist figure 1 In the schematic diagram of the oil-gas suspension and active suspension switching control circuit and the front view section of the suspension oil cylinder, the lower end cover 7 is fixedly connected to the lower end of the cylindrical outer cylinder 8, and the upper end of the outer cylinder is fixedly connected to the circular upper end cover 9 , oil ports are respectively provided on the wall of the outer cylinder near the upper and lower end caps. An inner cylinder 10 with an outer diameter corresponding to it is built in the center through hole of the upper end cover. The inner cylinder is a cylinder with a closed upper end. There are two oil ports on the wall of the inner cylinder, one of which is connected to the inner rodless cavity. A is connected, and the other oil port is connected with rod cavity B inside. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com