Outdoor material deoiling treatment method and anti-corrosion treatment method utilizing same

A treatment method and anti-corrosion treatment technology, applied in wood treatment, wood heat treatment, wood treatment details, etc., can solve the problems of aggravation of high temperature heat treatment, shedding of tree nodes, paint peeling, etc., and achieve good impregnation effect, low vacuum pressure, good penetration. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

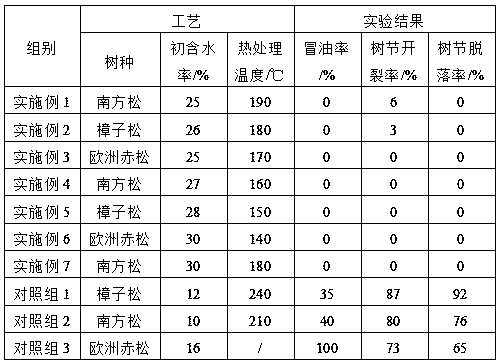

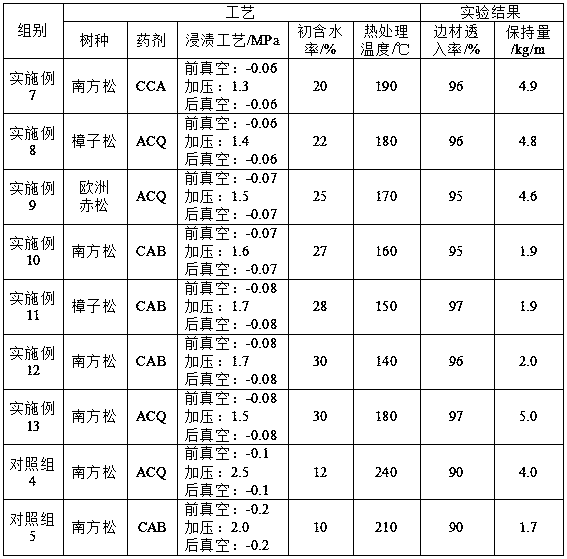

Examples

Embodiment 1

[0034] Embodiment 1: A method for deoiling outdoor materials. The material to be processed is southern pine, and the specifications are commercially available boards. It is carried out in a carbonization kiln, and includes the following steps in turn,

[0035] (1) Steps of oil-water mixing treatment: the treated material is dry wood, and any method of moisture absorption and callback by the prior art (for example, placing the treated material in an environment of 30°C / 96%RH for callback treatment) will The moisture content of the material to be treated is adjusted to 25 (±2)%; in this step, rosin, turpentine, resin and enough water are mixed to reduce their boiling point and volatilization temperature.

[0036] (2) Steps of high temperature heat treatment: including the heat treatment stage and the drying treatment stage; first, in the heat treatment stage, keep the temperature difference between dry and wet bulbs less than 1° until the wet bulb temperature rises to 105 (± 2) ℃...

Embodiment 2

[0038] Embodiment 2: a kind of method of outdoor material deoiling treatment, the processed material is sylvestris sylvestris, and the specification is commercially available plate, carries out in carbonization kiln, comprises the following steps successively,

[0039] (1) Steps of oil-water mixing treatment: the treated material is wet wood, and the moisture content of the treated material is adjusted to 26 (±2 )%.

[0040] (2) Steps of high temperature heat treatment: including the heat treatment stage and the drying treatment stage; first, in the heat treatment stage, keep the temperature difference between dry and wet bulbs less than 1° until the wet bulb temperature rises to 110 (± 2) ℃, keep the wet bulb temperature And raise the dry bulb temperature to 180 (± 2) ℃, keep and treat at the highest temperature for 3.0 hours, so as to realize the deoiling treatment of the treated material; then in the drying treatment stage, keep the wet bulb temperature at 110 (± 2) °C, re...

Embodiment 3

[0042] Embodiment 3: A method for deoiling outdoor materials. The processed material is Scots pine, and the specifications are commercially available boards. It is carried out in a carbonization kiln, and includes the following steps in turn,

[0043] (1) The steps of oil-water mixing treatment: the treated material is dry wood, and any method of moisture absorption and callback by the prior art (for example, placing the treated material in an environment of 36°C / 92%RH for callback treatment) will The moisture content of the material to be treated is adjusted to 25 (± 2)%.

[0044] (2) Steps of high-temperature heat treatment: including the heat treatment stage and the drying treatment stage; first, in the heat treatment stage, keep the temperature difference between dry and wet bulbs less than 1° until the wet bulb temperature rises to 115 (±2) °C, and keep the wet bulb temperature And raise the dry bulb temperature to 170 (± 2) ℃, keep and treat at the highest temperature fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com