Device for polishing internal spherical surface of steel ball cold heading mold

A polishing device and an in-mold technology, which is applied in the direction of surface polishing machine tools, grinding drive devices, grinding/polishing equipment, etc., can solve the problems of reducing the number of flips, low efficiency, and inconvenient clamping of cylindrical molds, etc. Achieve the effects of improving work efficiency, preventing damage to the mold, and facilitating back and forth movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

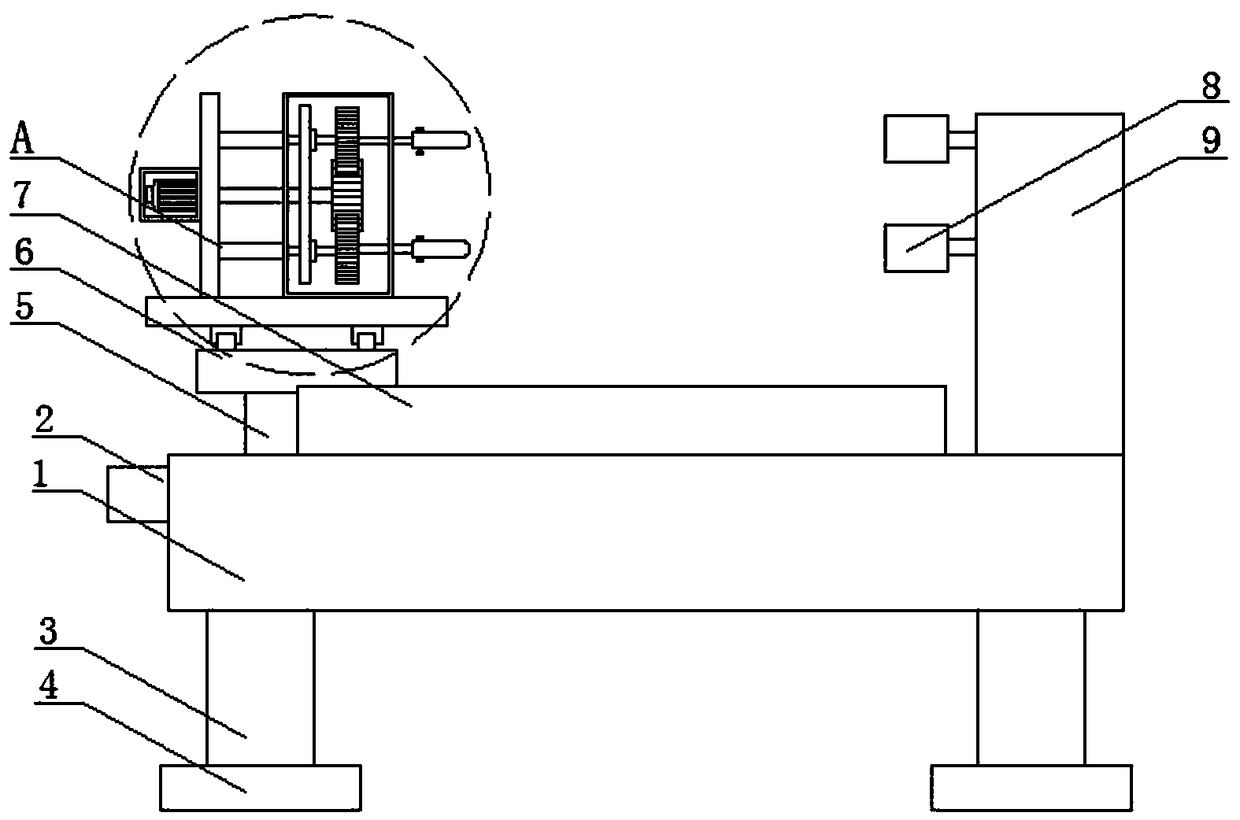

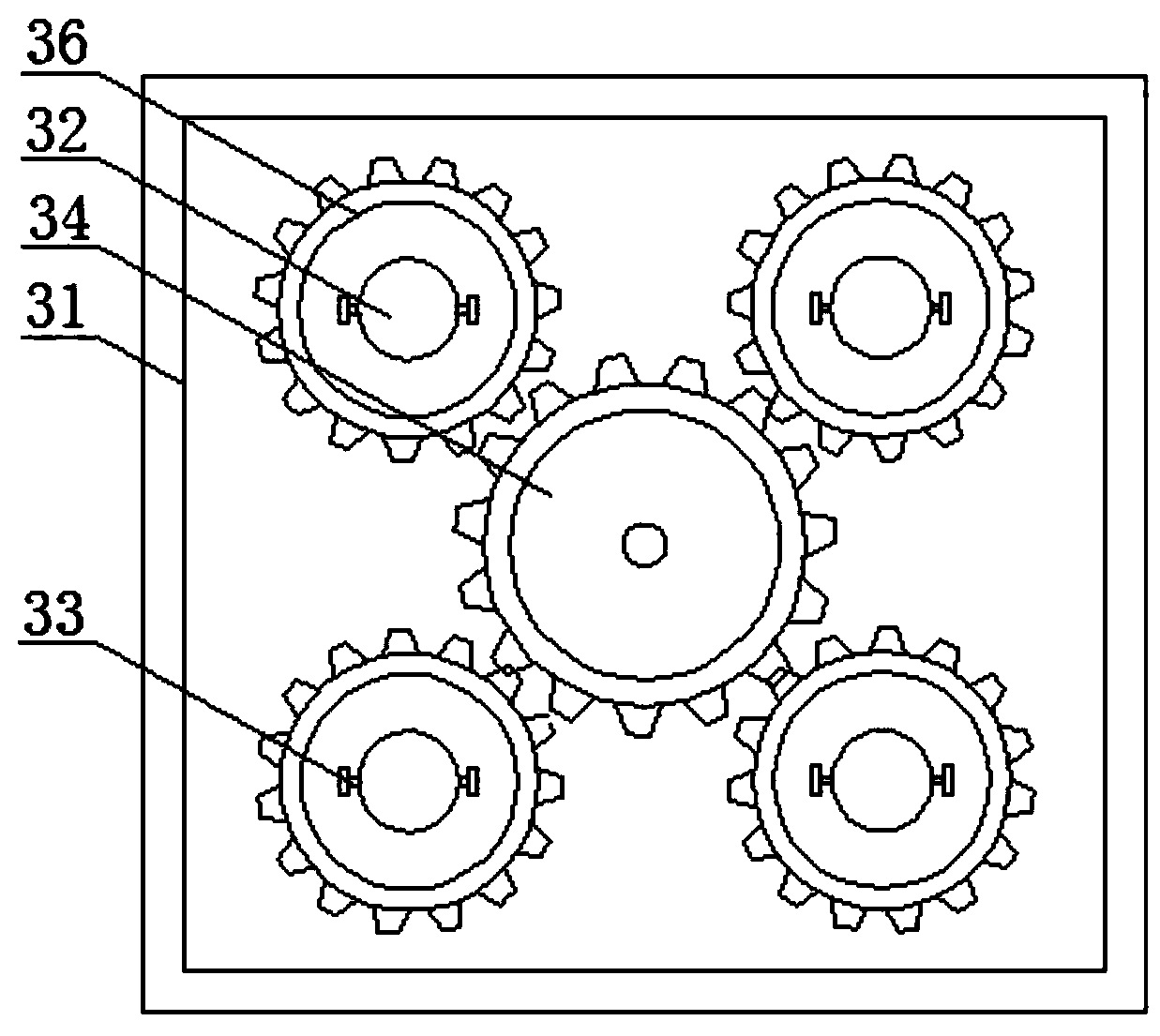

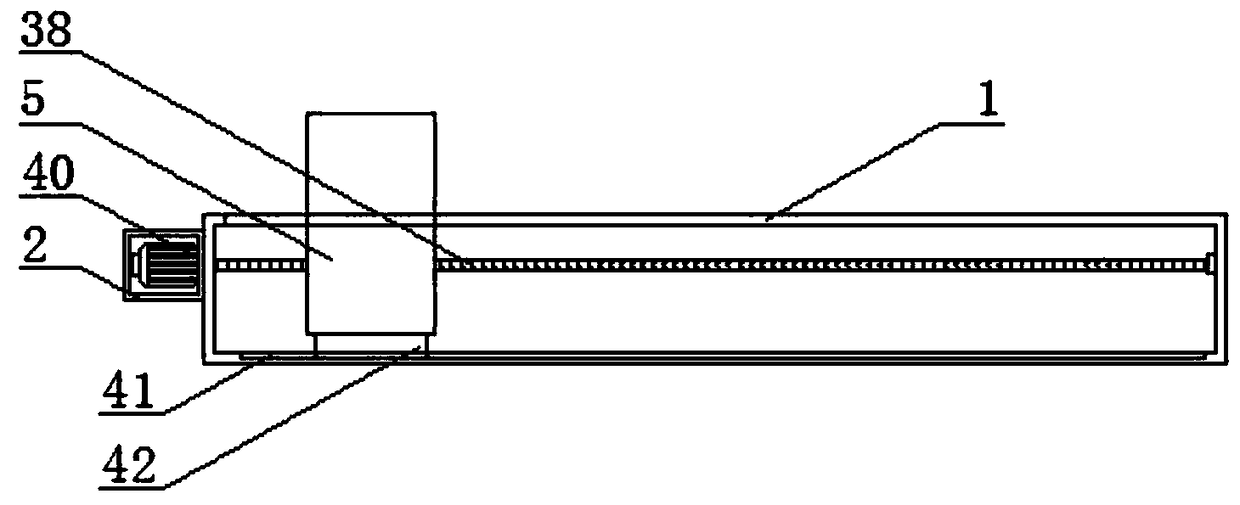

[0036] refer to Figure 1-7 , a spherical surface polishing device for steel ball cold heading dies, comprising a placing plate 1, the four corners of the lower end of the placing plate 1 are provided with supporting devices, the upper end side of the placing plate 1 is fixed with a mounting block 9, and one end of the mounting block 9 is equally spaced There are multiple clamping devices, the two ends of the placement plate 1 are provided with a first cavity, the first cavity is provided with a moving device, and the upper end of the first cavity is provided with a moving plate 5, which is convenient for driving the device to move left and right , near the position ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com