Full-automatic polishing machine for furnace drum

A fully automatic, polishing machine technology, used in grinding/polishing equipment, grinding racks, grinding machines, etc., can solve the problems of grinding dead corners, low grinding and polishing efficiency, and low degree of automation, so as to avoid grinding dead corners and workers. The effect of reduced labor intensity and stable and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

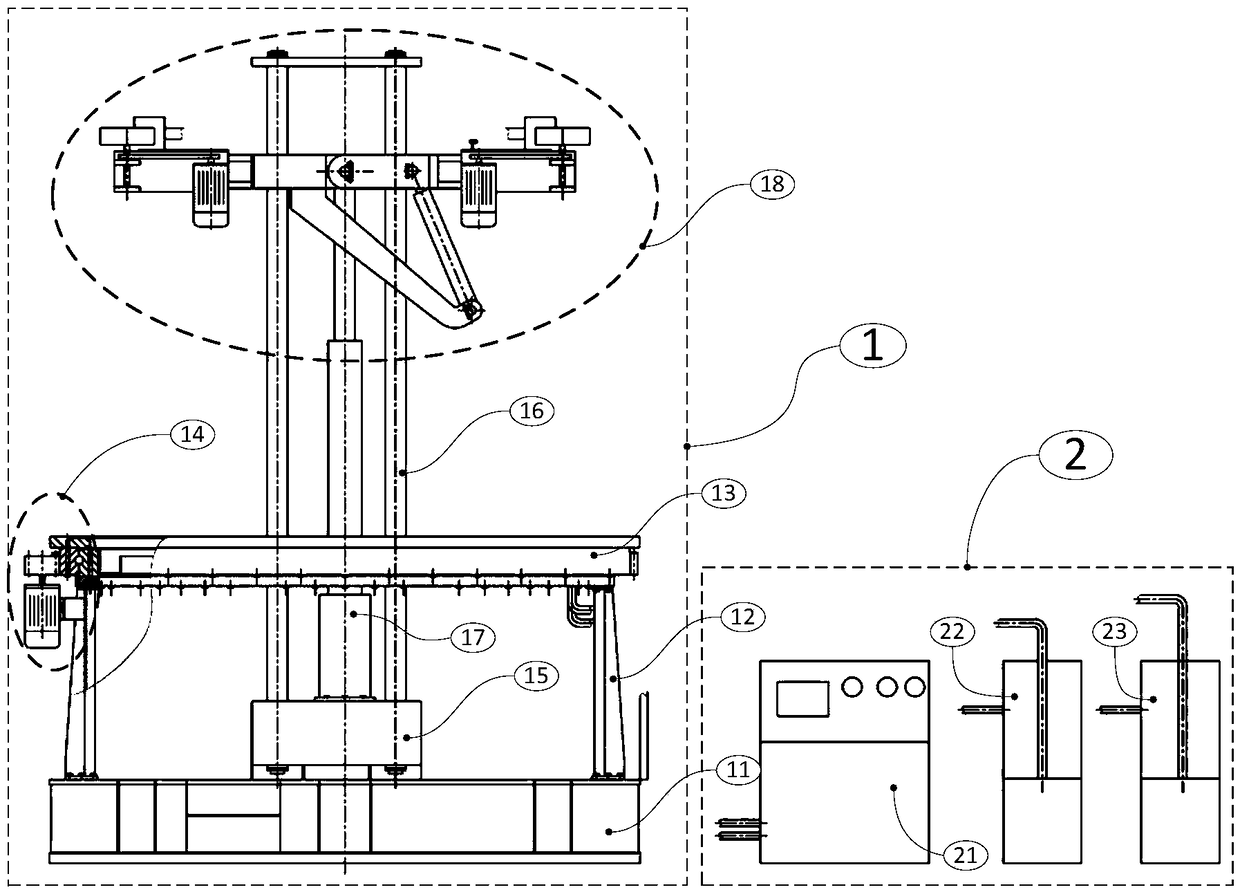

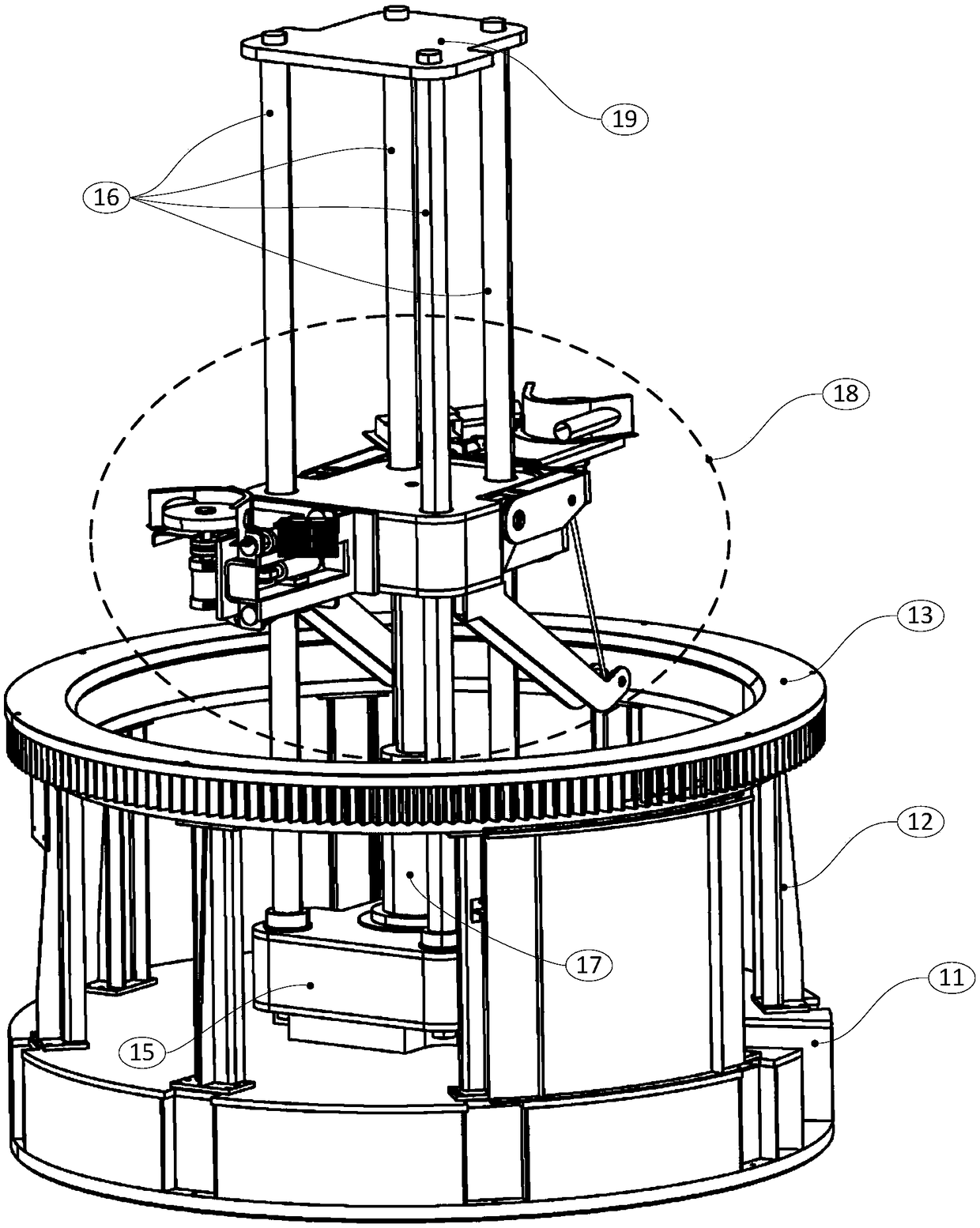

[0045] figure 1 Shown is a fully automatic furnace polishing machine according to a preferred embodiment of the present invention, which includes a working machine 1 and ancillary facilities 2 .

[0046] Such as figure 1 and 2 As shown, the working machine platform 1 includes a base 11 , a pillar 12 , a rotary table 13 , a rotary drive device 14 , a lifting guide mechanism (including 15 to 17 , 19 ) and a working mechanism 18 .

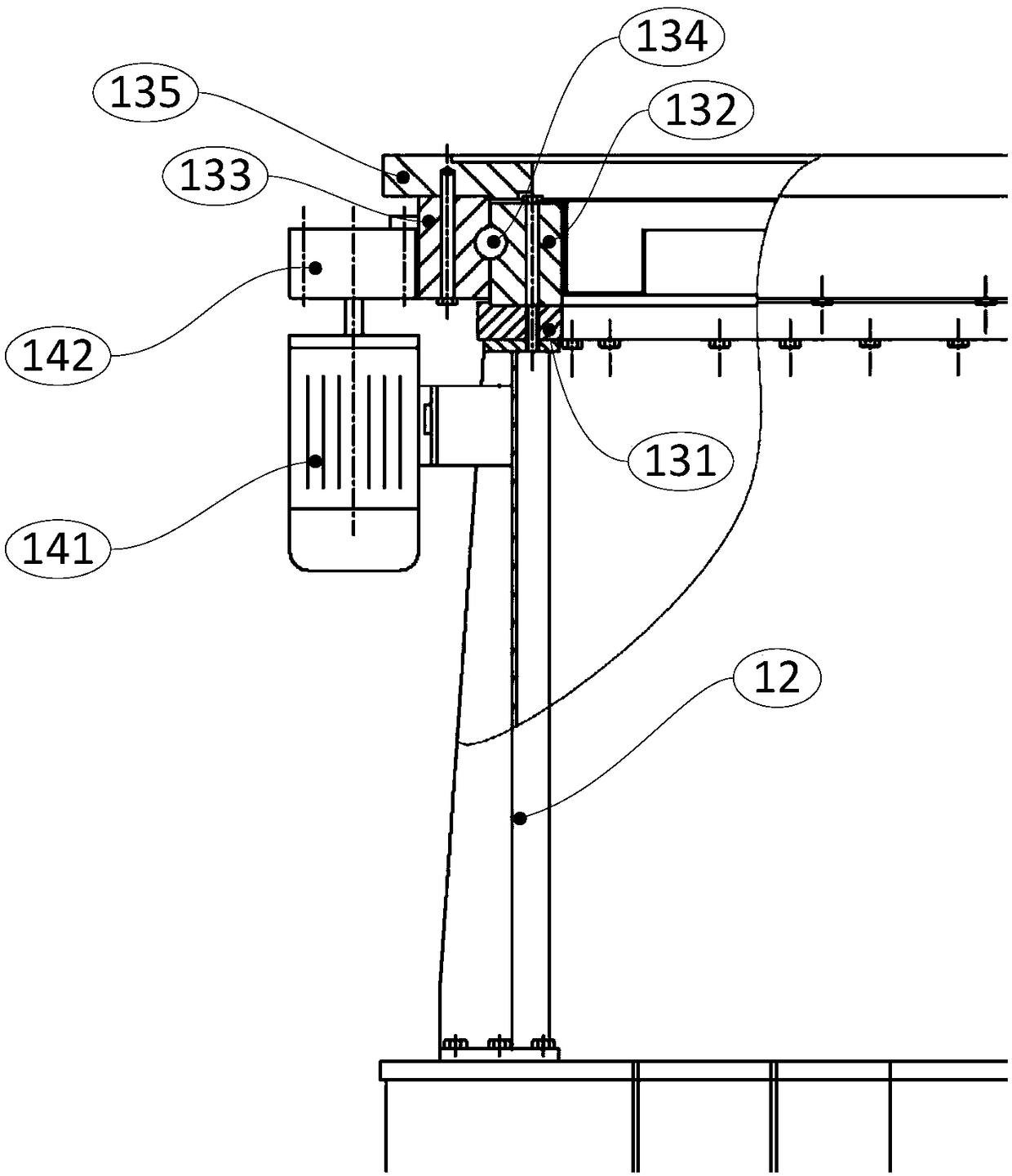

[0047] Wherein, the rotary table 13 is in the shape of a ring, and is used for holding the furnace cylinder to be processed. Such as image 3 As shown, the rotary table 13 includes a lower support ring 131, a bearing inner steel ring 132, a rotary gear 133 (with external teeth), a rotary steel ball 134 and an upper support ring 135, wherein the bearing inner steel ring 132, the rotary gear 133 and the rotary Steel ball 134 forms slewing bearing (a kind of standard part). The lower support ring 131 is supported and fixed on the base 11 by the supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com