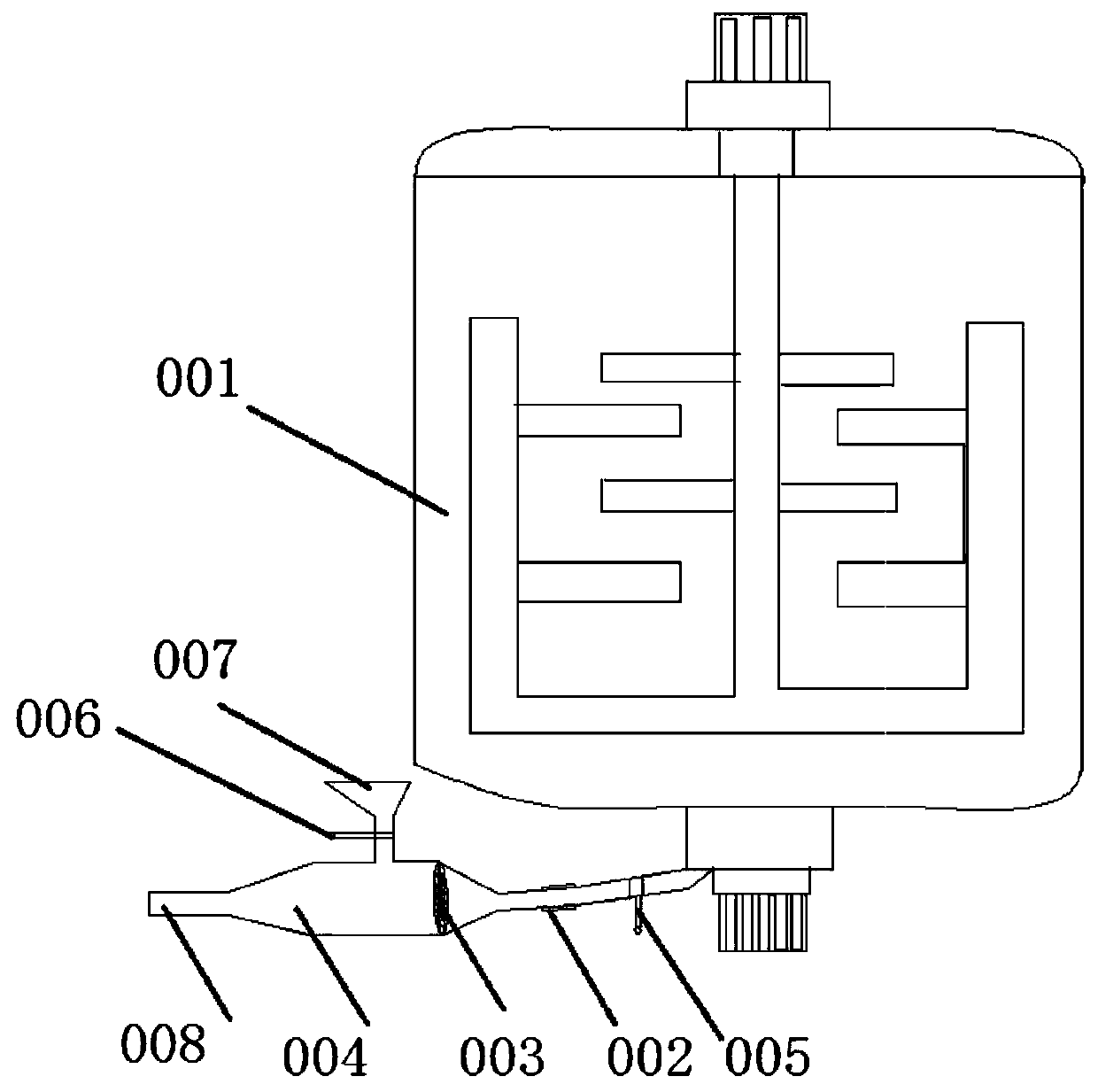

Method and device for preparing particle-containing cosmetics

A technology for cosmetics and granules, which is applied in chemical instruments and methods, separation methods, mixing methods, etc., can solve the problems of long defoaming time, high energy consumption, and difficulty in preparing uniformly dispersed cosmetics containing granules, so as to reduce operating strength and energy Consumption, fast defoaming, easy to observe and controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1, preparation method of cosmetics containing particles

[0027] A) Put the oily raw material into the vacuum emulsifier, stir at 30rpm for 5min, homogenize at 3000rpm for 5min, heat to 85°C, stir and keep warm for 20min to dissolve the raw material;

[0028] B) adding water-based raw materials, stirring at 20 rpm for 20 minutes to dissolve the raw materials;

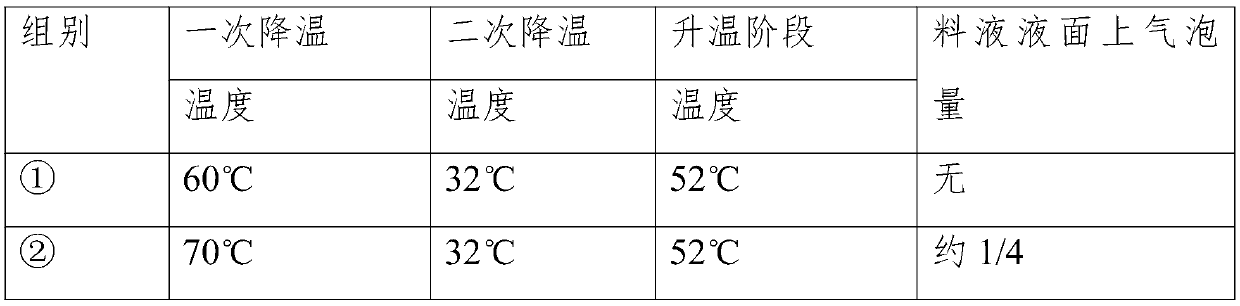

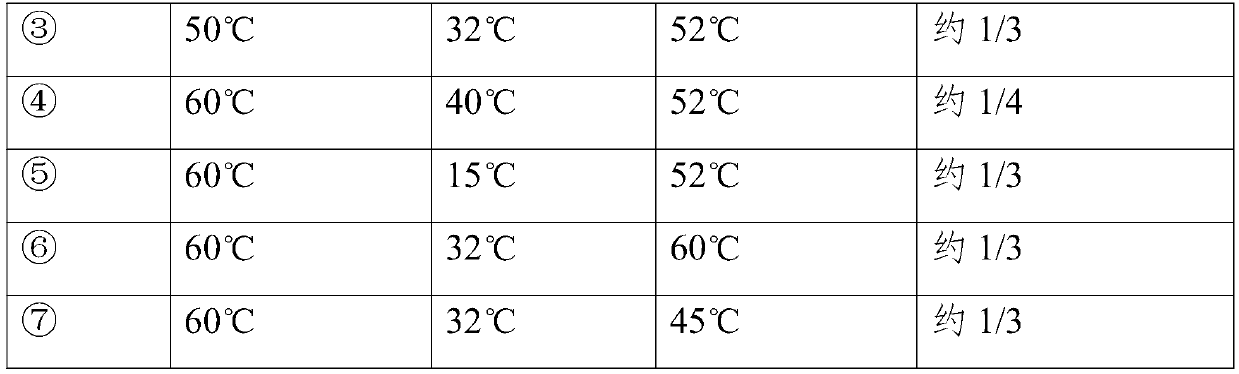

[0029] C) One-time cooling and defoaming: lower the temperature to 60°C, keep the vacuum at -0.03Mpa, stir at a stirring speed of 20rpm, and stir for 10min;

[0030] D) Second cooling and defoaming: the temperature is lowered to 32°C, the vacuum is maintained at -0.03Mpa, the stirring speed is 20rpm, and stirring is carried out for 3min;

[0031] E) Heating and defoaming: the temperature is raised to 52°C, the stirring speed is 20rpm, and stirring is carried out for 5 minutes;

[0032] F) Cool down to 45°C, add neutralizer to neutralize, stir evenly, and homogenize for 3 minutes; cool down to 40°C, a...

Embodiment 2

[0033] Embodiment 2, method for preparing cosmetics containing particles

[0034] Example 2 The difference from Example 1 is that step C) is cooled to 55°C, step D) is cooled to 25°C, step E) is heated to 50°C, and the remaining parameters and operations are as shown in Example 1.

Embodiment 3

[0035] Embodiment 3, method for preparing cosmetics containing particles

[0036] Example 3 The difference from Example 1 is that step C) is cooled to 65°C, step D) is cooled to 35°C, step E) is heated to 55°C, and the remaining parameters and operations are as shown in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com