Defoaming liquid storage tank used for vinegar filling process

A liquid storage tank and process technology, which is applied in the direction of liquid degassing, foam dispersion/prevention, and liquid degassing through filtration, etc. It can solve the problems of easy fouling of the stirring device, low work efficiency, and increased cost, and achieve defoaming efficiency High, easy to clean, improve the effect of fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

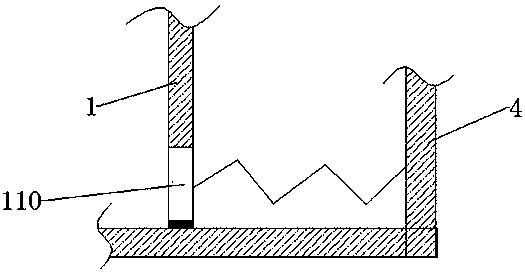

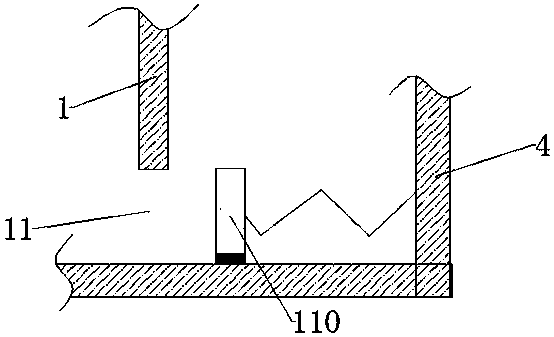

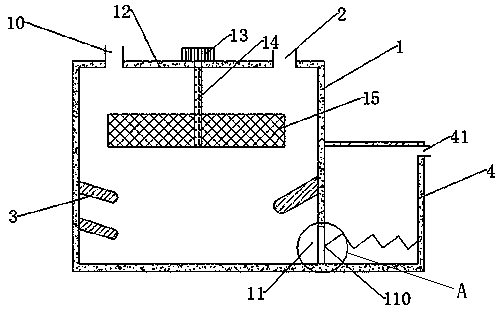

[0025] Such as figure 1 , shown in 2, a kind of defoaming liquid storage tank that is used for vinegar filling process, comprises tank body 1, the feed inlet 10 that is arranged on the tank body 1 top; Also includes the gas outlet 2 that is arranged on the tank body 1 top, The air outlet 2 is connected with a vacuum pump. Before filling, the liquid storage tank is exhausted, so that there is no air in the liquid storage tank during filling, so as to prevent the air from convecting the liquid when it flows in; the inner side of the tank body 1 Several heating plates 3 are arranged on the wall, and the heating plates 3 heat the liquid in the tank body 1, accelerate the flow velocity of the liquid molecules, reduce the stability of the bubbles, and achieve the purpose of eliminating the bubbles; the bottom end of the side wall of the tank body 1 is provided with a first Discharge port 11, the first discharge port 11 is provided with a spring retainer 110, and a layer of rubber is...

Embodiment 2

[0028] On the basis of the defoaming liquid storage tank used in the vinegar filling process described in Example 1, it is further optimized, and the heating plate 3 is detachably connected to the side wall. Because vinegar is easy to scale, the heating plate 3 is set to be detachable, and the heating plate 3 can be cleaned in time to increase the effective service life of the heating plate 3.

Embodiment 3

[0030] Further optimized on the basis of a defoaming liquid storage tank used in the vinegar filling process described in Example 1, the tank body 1 includes a tank cover 12, and the tank cover 12 is screwed to the side wall of the tank body 1 . The tank cover 12 can be disassembled, which is convenient for cleaning the inside of the tank body 1 and prevents the vinegar from polluting the device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com