Heat-not-burn cigarette and assembly thereof

A heat-not-burn, cigarette technology, applied in tobacco, cigar manufacturing, smoker’s supplies, etc., can solve problems such as inapplicable electric heating, unsuitable for heat-not-burn cigarettes, insufficient cooling of smoke temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

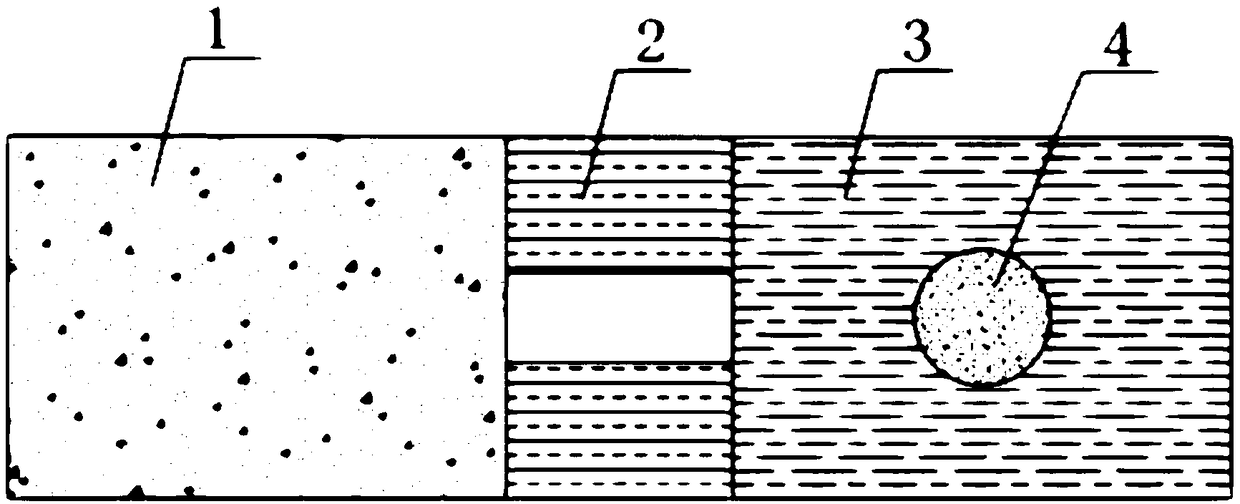

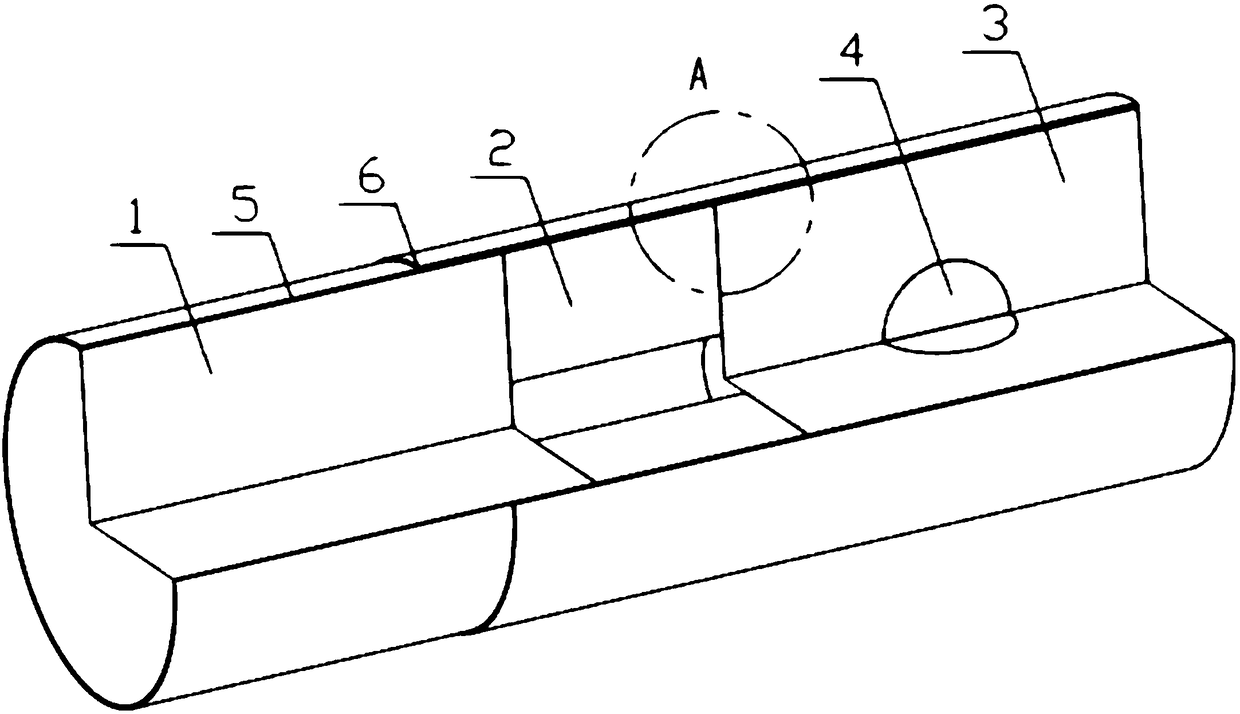

[0033] Such as Figure 1~3 As shown, a heat-not-burn cigarette includes a tobacco section 1, a cooling section 2, a filter section 3, a first forming paper 5, a tipping paper 6, and a second forming paper 7; the end of the tobacco section 1 and the cooling section 2 The front end of the cooling section 2 is connected to the front end of the filter section 3; the first forming paper 5 wraps the tobacco section 1 to form a cigarette; the second forming paper 7 wraps the cooling section 2 and the filtering section to form a composite filter rod; Paper loading 6 is used to wrap cigarettes and composite filter rods together; cooling section 2 is a hollow filter rod made of acetate fiber, food-grade plastic paper or fiber paper; filter section 3 is a solid filter rod made of polylactic acid fiber.

[0034] Tobacco section 1 is a low-temperature tobacco product, and tobacco components can be volatilized below 300°C. Tobacco segment 1 can be made of tobacco materials such as tobacco ...

Embodiment 2

[0042] The heat-not-burn cigarette in Example 1 is generally used in conjunction with a special low-temperature heating smoking appliance, and cannot be used alone. The heating element of the heating device can be a cylindrical heating element with a taper at one end, or an arrow-shaped thin sheet heating element. The heating element penetrates the tobacco section, and the novel heat-not-burn cigarette described in the present invention is heated from the core of the tobacco section. heating.

[0043] Such as Figure 4 As shown, a heat-not-burn cigarette assembly includes the heat-not-burn cigarette in Example 1 and a low-temperature heating smoking device 8 . The low-temperature heating smoking appliance includes a heating device and a heating element connected to the heating device. The top of the heating element is a tip, and the tip of the heating element penetrates into the tobacco section 1 of the heat-not-burn cigarette for heating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com