Flavor-enhancing essence and preparation method thereof

An essence and spice technology, applied in the field of food processing, can solve the problems of reducing the Maillard reaction intensity, affecting the formation of food and umami, thick taste, and increasing the content of harmful by-product acrylamide, etc., so as to increase the added value of the oil industry, The effect of stable and long-lasting flavor and increased solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

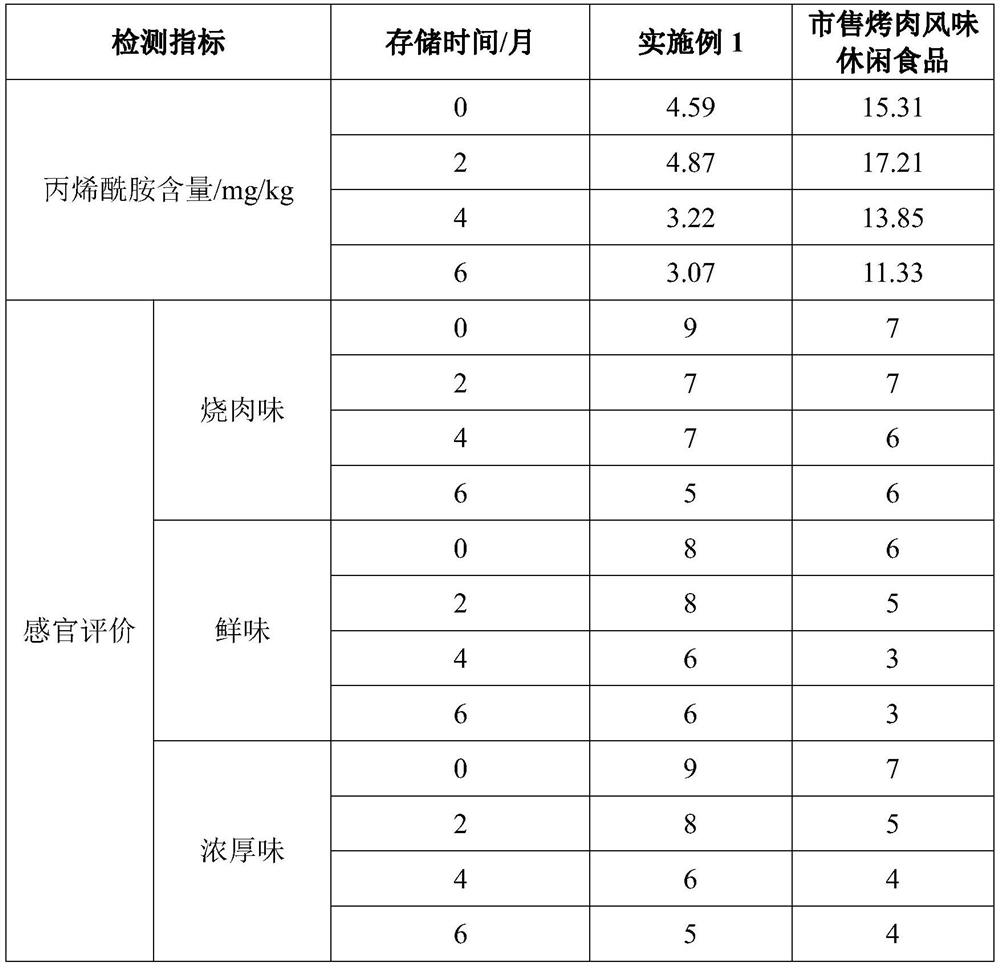

Embodiment 1

[0036] A flavor-enhancing flavor is obtained by using defatted cake powder as a raw material, enzymolysis, and microwave-assisted Maillard reaction at low water activity, and then uniformly mixing the reaction product with spice compound powder;

[0037] The flavor-enhancing essence is a yellow powdery solid, has a flavor similar to traditional barbecue, and the flavor is stable for more than 6 months.

[0038] The preparation steps of flavor-enhancing essence are as follows:

[0039] (1) Preparation of defatted cake powder enzymatic hydrolyzate

[0040] Get 2000g of defatted linseed cake powder with a protein content of 25%, add water to dissolve, and prepare an aqueous solution of defatted linseed cake with a mass concentration of 6%, add alkaline protease 20g, composite protease 20g and tyrosine to the aqueous solution A total of 60 g of mixed enzyme A consisting of 20 g of acid enzyme (mass ratio 1:1:1), added 1 mol / L sodium hydroxide solution to adjust the pH value to 7....

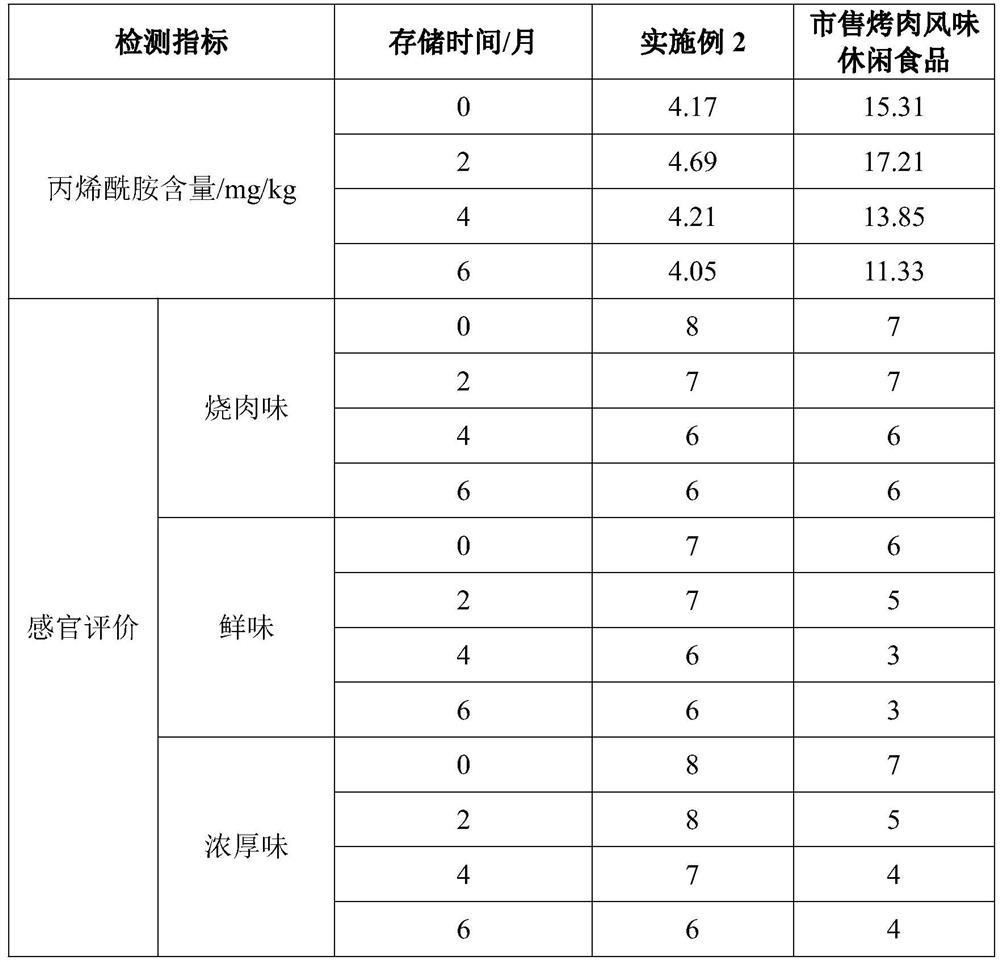

Embodiment 2

[0060] A flavor-enhancing essence is obtained by using defatted cake powder as raw material, enzymolysis, microwave-assisted Maillard reaction under low water activity, and then uniformly mixing the reaction product with spice compound powder; the flavor-enhancing essence is brown The powdery solid has a flavor similar to traditional barbecue, and the flavor is stable for more than 6 months.

[0061] The preparation steps of flavor-enhancing essence are as follows:

[0062] (1) Preparation of defatted cake powder enzymatic hydrolyzate

[0063] Get the defatted peony seed cake powder 2000g that protein content is 50%, add water to dissolve, preparation mass concentration is the defatted peony seed cake aqueous solution of 12%, in this aqueous solution, add alkaline protease 60g, compound protease 20g and tyrosine A total of 100g of mixed enzyme A consisting of 20g of acidase (mass ratio 3:1:1), added 1mol / L sodium hydroxide solution to adjust the pH to 7.5, reacted at a temper...

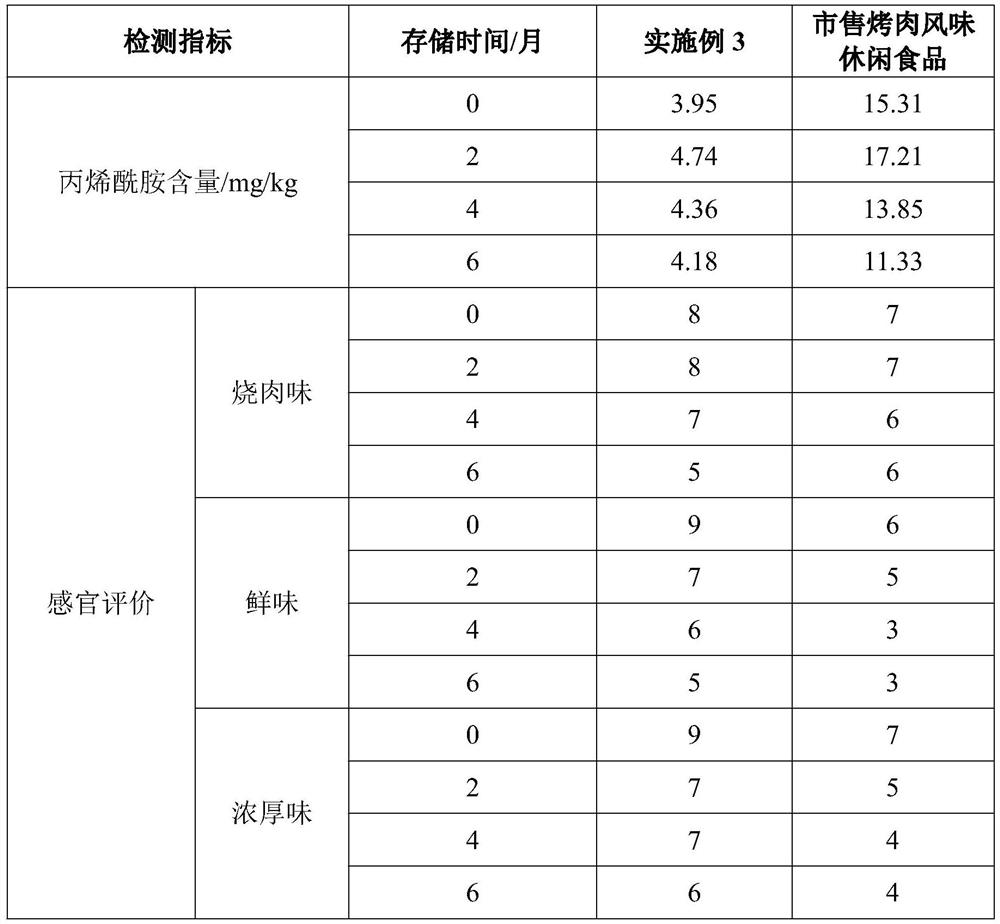

Embodiment 3

[0083] A flavor-enhancing flavor is obtained by enzymatic hydrolysis and microwave-assisted Maillard reaction at low water activity, using defatted cake powder as raw material, and then uniformly mixing the reaction product with spice compound powder; the flavor-enhancing flavor is brown The powdery solid has a flavor similar to traditional barbecue, and the flavor is stable for more than 6 months.

[0084] The preparation steps of flavor-enhancing essence are as follows:

[0085] (1) Preparation of defatted cake powder enzymatic hydrolyzate

[0086] Get the defatted walnut cake powder 1000g that the protein content is 45%, the defatted sunflower seed cake powder 1000g that the protein content is 37%, add water to dissolve, preparation mass concentration is the defatted cake flour aqueous solution of 10%, in this aqueous solution, add A total of 80g of mixed enzyme A consisting of 40g of alkaline protease, 20g of composite protease and 20g of tyrosinase (mass ratio 2:1:1), ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com