Front ditcher and ditching method

A ditching machine and front-mounted technology, which is applied in the directions of planting methods, excavation/covering of trenches, application, etc., can solve the problems of low efficiency, laborious, inconvenient operation, etc., and achieve the goal of improving ditching efficiency and convenience Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

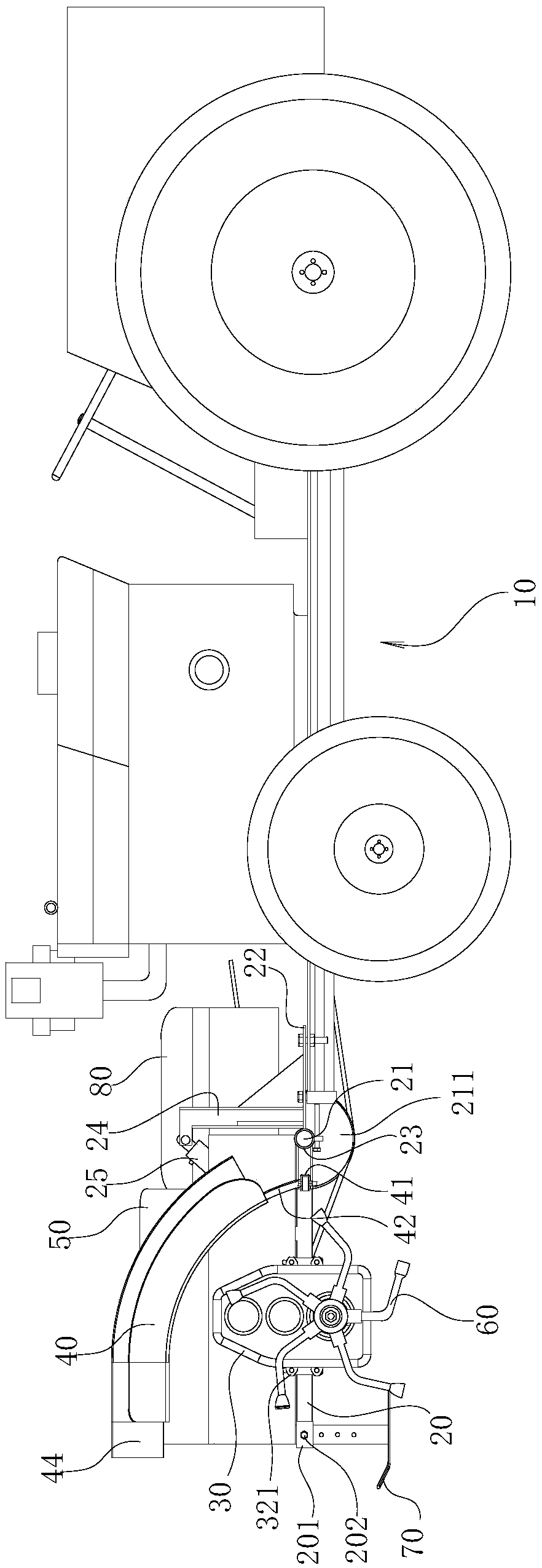

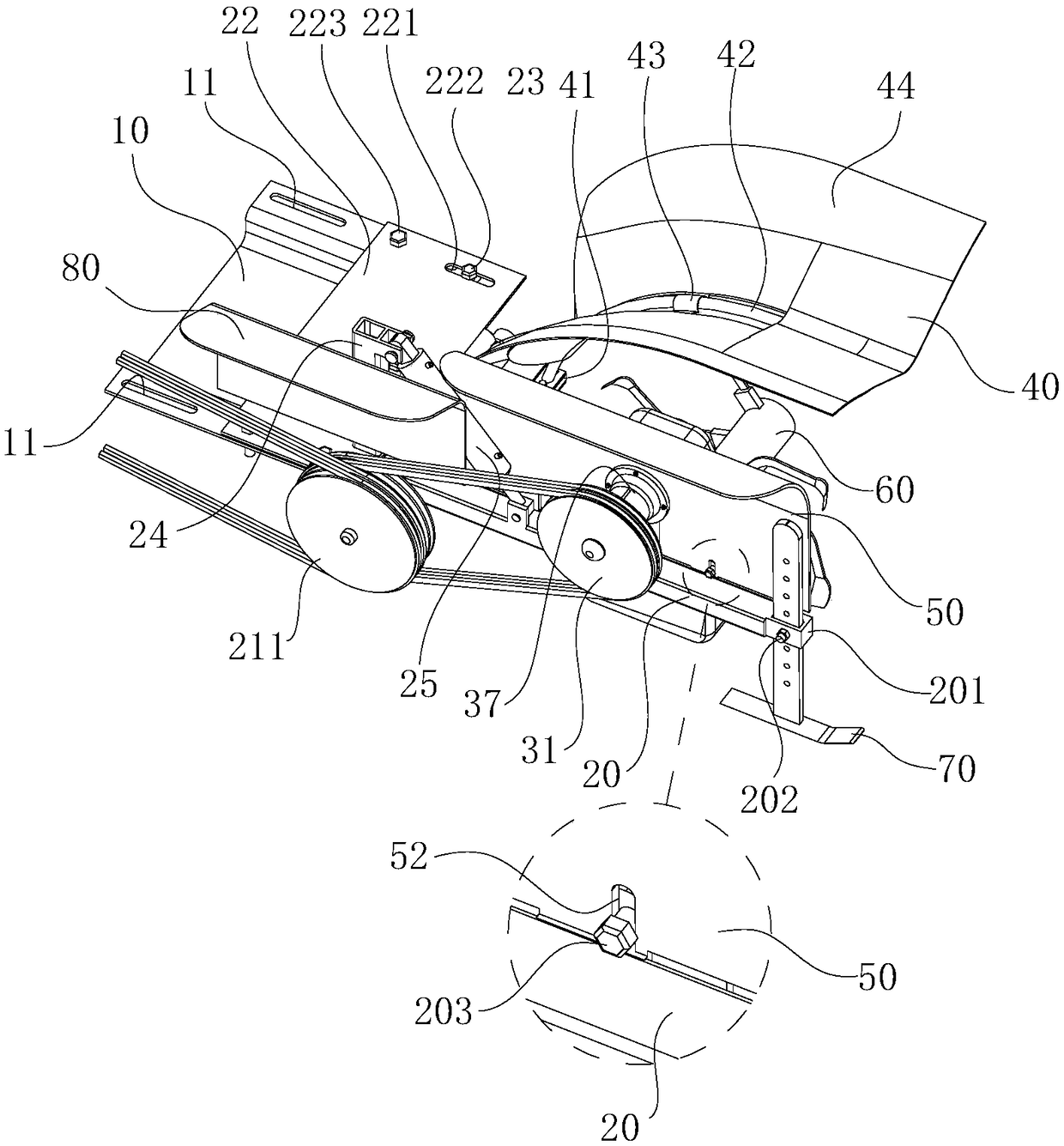

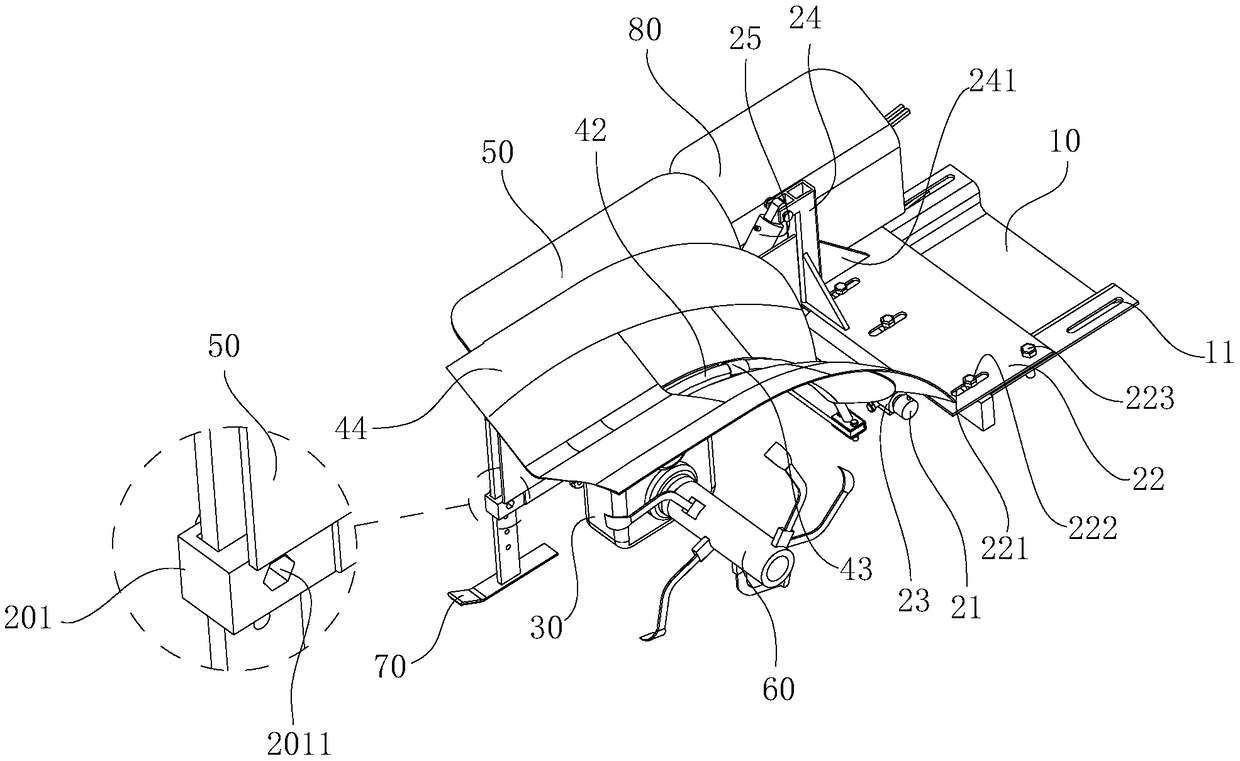

[0030] refer to Figure 1 to Figure 7 , the structural features of this front-mounted ditching machine are described in detail as follows:

[0031] The front-mounted ditching machine includes a frame 20 hingedly connected to the front end of the four-wheel tractor 10, the hinge axis of the frame 20 is horizontal and the length direction is perpendicular to the vehicle length direction of the four-wheel tractor 10, and the frame 20 is provided with There is a gearbox 30, the input shaft of the gearbox 30 is connected with the driving wheel of the four-wheel tractor 10 through a transmission mechanism, the output shaft of the gearbox 30 is provided with a ditching tool assembly 60, and the four-wheel tractor 10 A height adjustment mechanism is provided, and the height adjustment mechanism is used to adjust the rotation of the frame 20 around the hinge axis;

[0032] to combine figure 1 and figure 2 As shown, the ditching tool assembly 60 used for ditching is fixed on the fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com