A graphene aerogel modified proton exchange membrane for fuel cell and preparation method thereof

A graphene aerogel, proton exchange membrane technology, used in fuel cells, circuits, electrical components, etc., can solve problems such as low conductivity and poor stability, achieve excellent electrical conductivity, improve electrical conductivity, and inhibit swelling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

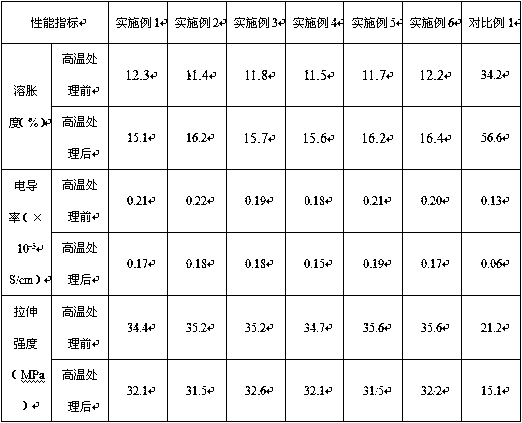

Examples

Embodiment 1

[0035] The preparation process is:

[0036](1) Evenly disperse graphite oxide in a mixed solution of ethanol and water to prepare a slurry, then add ethylenediamine, and heat up to react, and reduce and peel off graphite oxide through ethylenediamine to obtain graphene hydrogel Glue; in the mixed solution of ethanol and water, 1 weight part of ethanol, 99 weight parts of water; In the reaction system, 15 weight parts of graphite oxide, 80 weight parts of mixed solution, 5 weight parts of ethylenediamine; The temperature of reaction is 97 ℃, The reaction time is 8h;

[0037] (2) Dry the graphene hydrogel prepared in step (1) under freezing conditions, and use ammonia gas blowing to make the graphene gel evenly dispersed, inhibit the stacking and assembly of particles, and then filter to remove the solvent to obtain Granular graphene airgel; the average particle size of graphene airgel is 1.5μm, and the pore size is 30nm;

[0038] (3) Put the graphene airgel prepared in step (...

Embodiment 2

[0048] The preparation process is:

[0049] (1) Evenly disperse graphite oxide in a mixed solution of ethanol and water to prepare a slurry, then add ethylenediamine, and heat up to react, and reduce and peel off graphite oxide through ethylenediamine to obtain graphene hydrogel glue; in the mixed solution of ethanol and water, 2 parts by weight of ethanol, 98 parts by weight of water; in the reaction system, 13 parts by weight of graphite oxide, 82 parts by weight of mixed solution, and 5 parts by weight of ethylenediamine; the temperature of the reaction is 92 ° C, The reaction time is 9h;

[0050] (2) Dry the graphene hydrogel prepared in step (1) under freezing conditions, and use ammonia gas blowing to make the graphene gel evenly dispersed, inhibit the stacking and assembly of particles, and then filter to remove the solvent to obtain Granular graphene airgel; the average particle size of graphene airgel is 1.4μm, and the pore size is 10nm;

[0051] (3) Put the graphen...

Embodiment 3

[0061] The preparation process is:

[0062] (1) Evenly disperse graphite oxide in a mixed solution of ethanol and water to prepare a slurry, then add ethylenediamine, and heat up to react, and reduce and peel off graphite oxide through ethylenediamine to obtain graphene hydrogel Glue; in the mixed solution of ethanol and water, 1 weight part of ethanol, 99 weight parts of water; In the reaction system, 12 weight parts of graphite oxide, 84 weight parts of mixed solution, 4 weight parts of ethylenediamine; The temperature of reaction is 90 ℃, The reaction time is 9h;

[0063] (2) Dry the graphene hydrogel prepared in step (1) under freezing conditions, and use ammonia gas blowing to make the graphene gel evenly dispersed, inhibit the stacking and assembly of particles, and then filter to remove the solvent to obtain Granular graphene airgel; the average particle size of graphene airgel is 1.3μm, and the pore size is 2nm;

[0064] (3) Put the graphene airgel prepared in step (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com