Pressure-resistant acoustic filter for truncation parametric array and design method

A filter and parametric array technology, which is applied in the field of pressure-resistant acoustic filters and design of truncated parametric arrays, can solve the problem of reduced sound insulation effect, insufficiency of acoustic filters, and inability to effectively cut off high-frequency initial waves and sum-frequency sound waves. and other problems to achieve the effect of meeting the pressure resistance requirements and ensuring the transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with accompanying drawing:

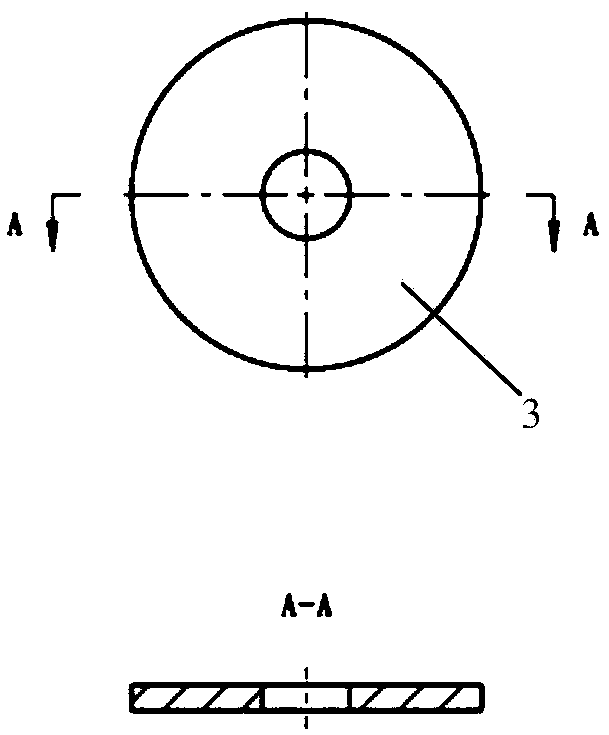

[0029] see Figure 1 to Figure 4 The pressure-resistant acoustic filter of the present invention includes structural parts such as front plate 1, rear plate 2, connecting piece 3 and bolt 4, and the material of the structural parts is selected from corrosion-resistant stainless steel materials, such as 304, 316, etc., preferably 316, front plate, The back plate requires the plate to be uniform in texture, flat and free of obvious deformation. The front plate 1 has a bolt hole 5 penetrating through the front plate 1 , and the bolt hole 5 is an unthreaded counterbore, and two hoisting holes 11 are provided at the protruding part above the front plate 1 . The back plate 2 has a bolt hole 6 penetrating through the back plate 2 , and the bolt hole 6 is a threaded through hole. Two hoisting holes 21 are also provided at the protruding part above the back plate 2 . The shape a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com