Building electrical automation production system based on BIM model

A technology for building electrical and production systems, applied in the field of building construction, can solve problems such as increasing human resources and construction time, inconvenient installation and construction connections, and inconsistent measurement lengths, achieving fine design, saving time, and reducing measurement errors. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be further specifically described below through embodiments and in conjunction with the accompanying drawings.

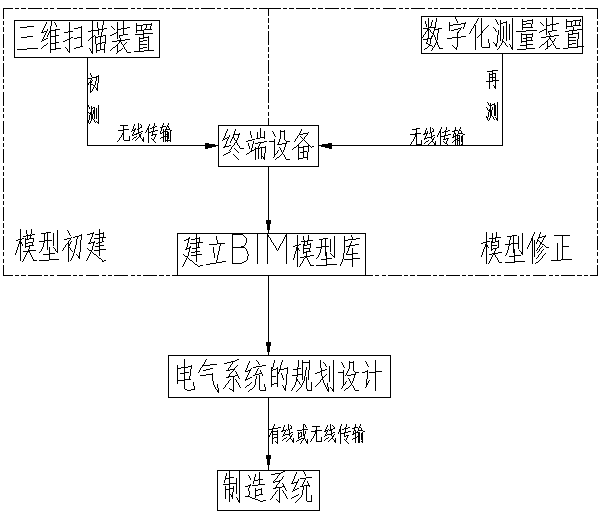

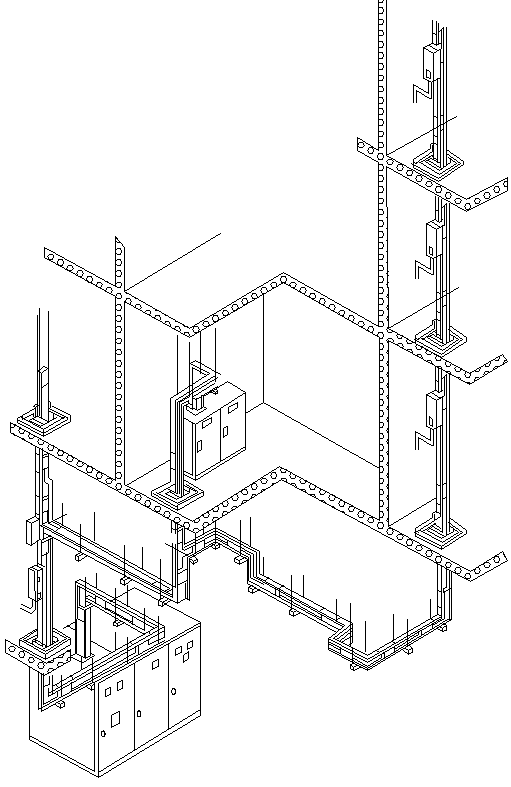

[0020] Such as figure 1 , figure 2 As shown, a BIM model-based building electrical automation production system, the BIM model-based building electrical automation production system includes a three-dimensional scanning device, a BIM model library and a digital measurement device, and the three-dimensional scanning device is used to monitor the construction site of the building Scanning and obtaining three-dimensional data of the construction site, the three-dimensional data obtained by the three-dimensional scanning device is sent to the terminal device through wireless transmission, and a preliminary drawing of the virtual building model of the construction site is performed on the terminal device;

[0021] The digital measurement device re-measures the site, and re-sends the measured information to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com