Cold rolled strip steel galvanizing line process control method

A process control, cold-rolled strip technology, applied in program control, electrical program control, comprehensive factory control, etc., can solve problems such as inability to meet small batch, multi-variety order requirements, inability to support mathematical models, and multiple manual interventions , to achieve the effect of improving the convenience of use, improving the level of process control, and improving the process control system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

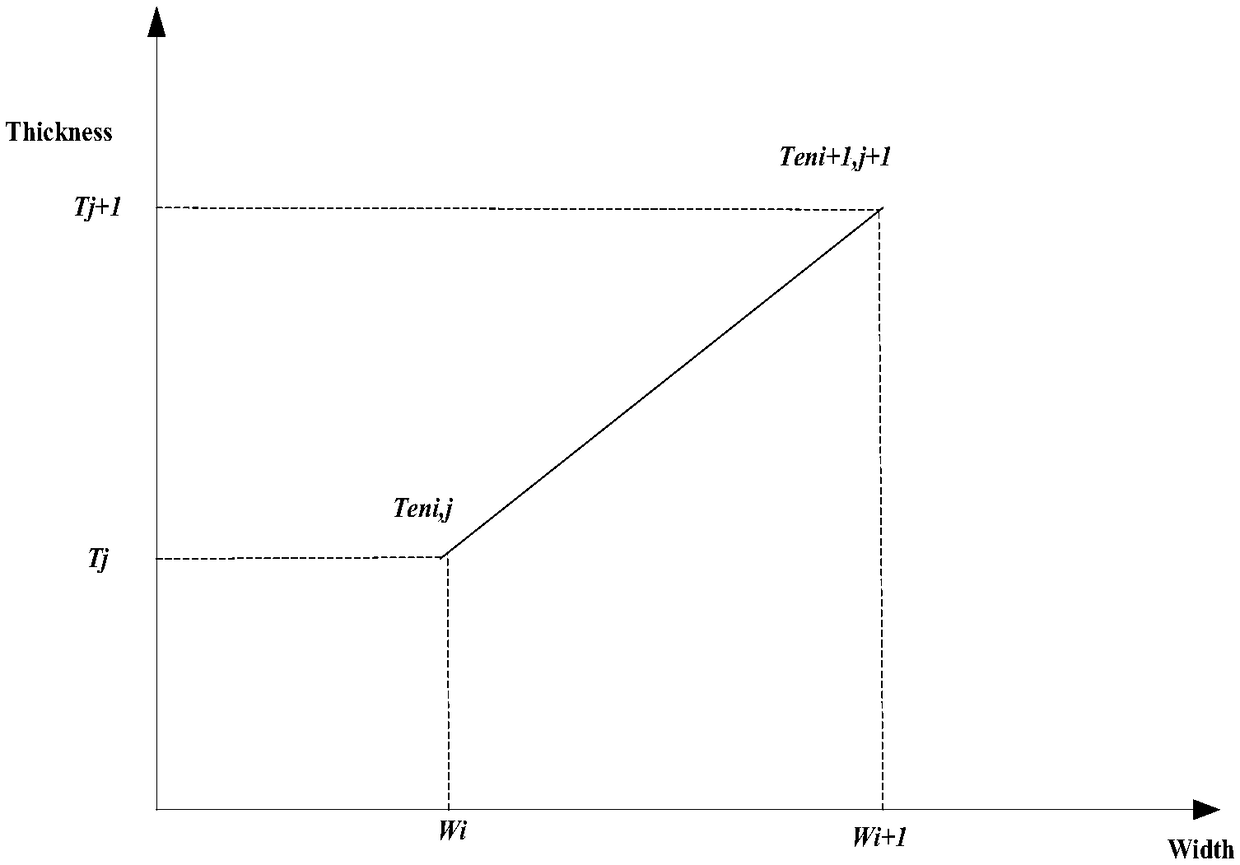

[0013] A process control method for a cold-rolled steel strip galvanizing line, the steps are as follows: classify the steel strips to be produced through the steel classification algorithm; For strip steel, this value is used to correct the calculated value; at the same time, the linear difference algorithm is used to solve the corresponding parameter set value; for the obtained set value, the operator has the authority to modify it according to the actual situation of the equipment; the set value is confirmed If there is no error, start production; all historical data is stored, and offline optimization is performed to fit the set value curve.

[0014] The linear difference algorithm is used to solve the corresponding parameter setting values, and the setting values are calculated and generated for mechanical equipment located in different p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com