Cooperative purification system for oil fume and volatile organic substances of catering service units

A volatile organic compound, service unit technology, applied in the field of cleaning and sanitary equipment, to achieve the effect of novel and unique structure, good effect and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

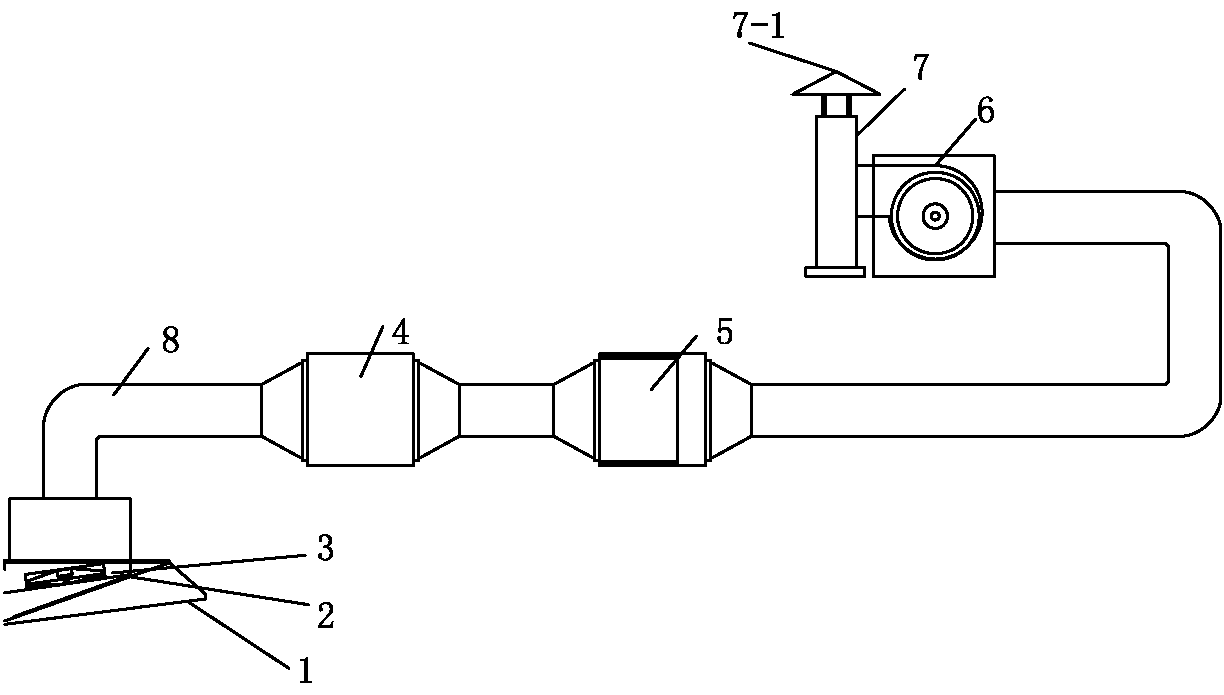

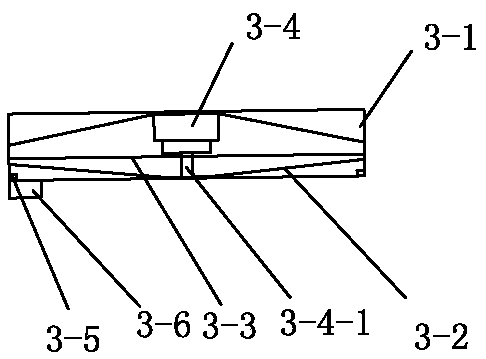

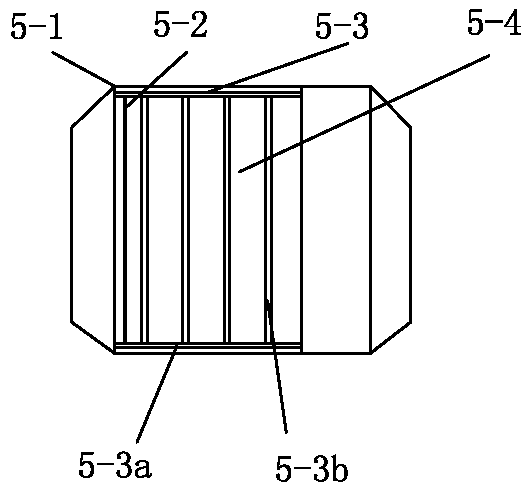

[0014] Depend on Figure 1-3 As shown, the present invention is a synergistic purification system for cooking fumes and volatile organic compounds in a catering service unit. Inside the hood 1, the outlet of the oil extraction fume device 3 is connected to the air inlet of the exhaust device, and the oil collection fume hood 1 is equipped with a front grille 2 in front of the inlet of the oil extraction fume device. The oil extraction fume device (module) 3 includes a housing 3-1, a grille equalizer 3-2, a dynamic centrifugal filter 3-3 and a motor 3-4, and the upper center of the housing 3-1 is equipped with a downward The motor 3-4, the dynamic centrifugal filter screen 3-3 of vertical plane is housed on the motor shaft 3-4-1, and the grille equalizing plate 3-3 that is inclined-plane shape is housed in the shell of dynamic c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com