A prepackaged automatic filling device for assembly line operation of attitude and orbit control power system

A power system and automatic filling technology, applied in the pipeline system, gas/liquid distribution and storage, mechanical equipment, etc., can solve problems such as filling failure, improve filling efficiency, improve filling quality stability, reduce The effect of the possibility of human error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with specific embodiments.

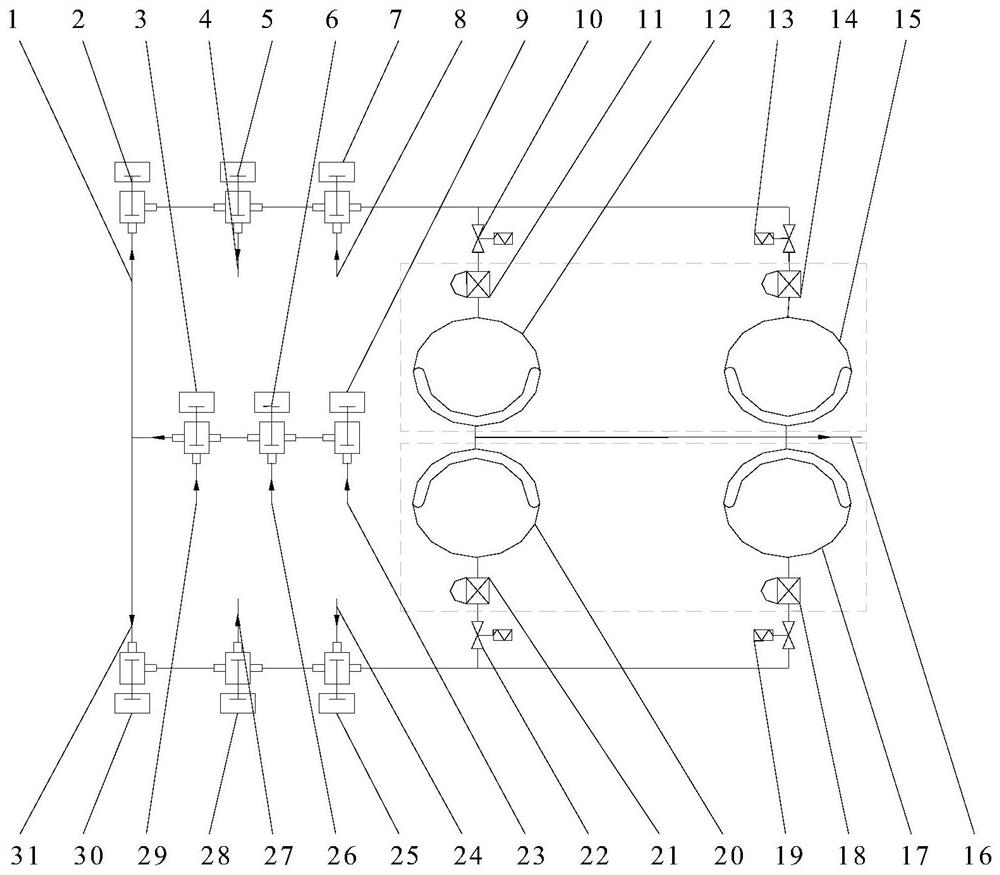

[0025] Such as figure 1 As shown, a pre-packaged automatic filling device for assembly line operation of attitude control power system, including vacuum unit, propellant supply unit, cleaning and blowing unit and product unit;

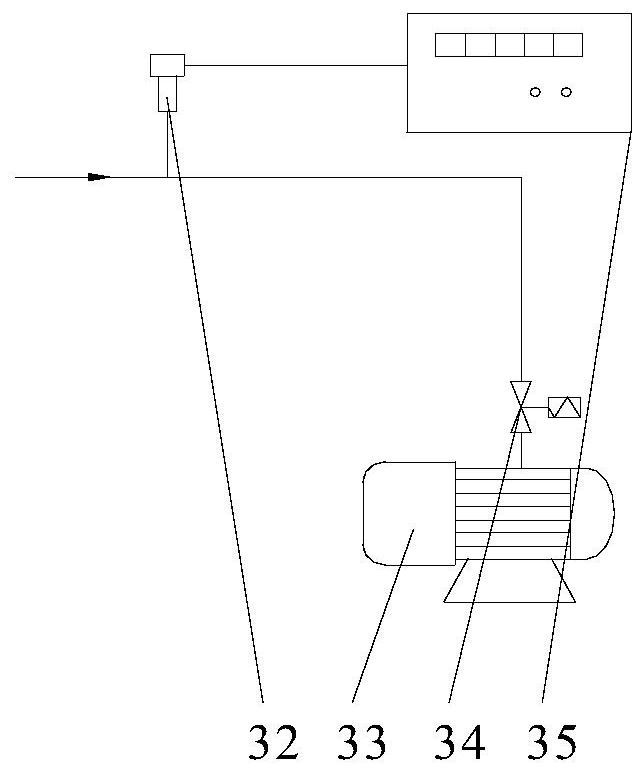

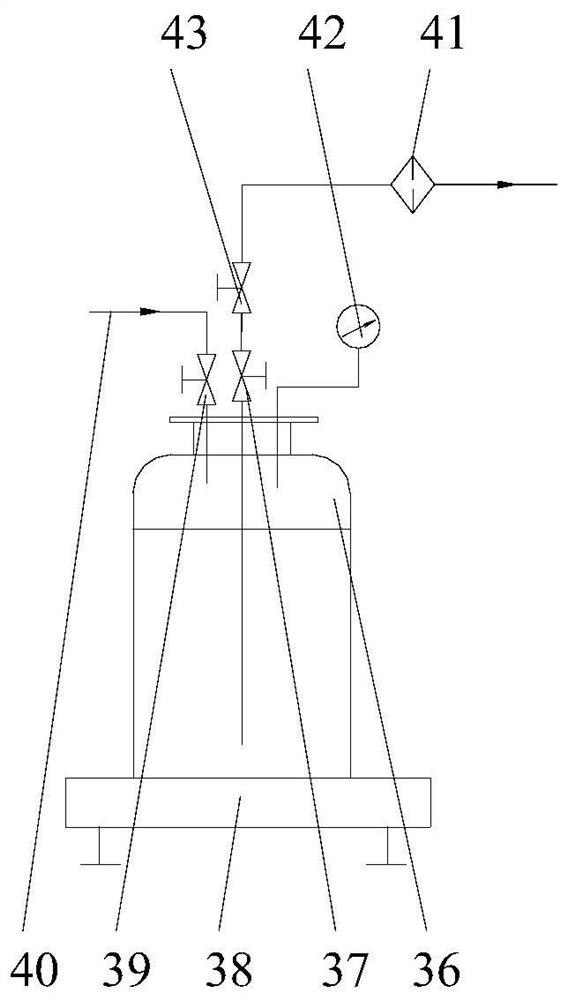

[0026] The vacuum pumping unit is composed of a vacuum pump 33, a vacuum gauge 32, a vacuum gauge 35, a vacuum solenoid valve 34, an air chamber vacuum port 16, a liquid chamber vacuum port I4, a liquid chamber vacuum port II27, and a pneumatic vacuum control valve I5. , Pneumatic vacuum control valve Ⅱ28 and vacuum pipeline; vacuum pump 33 is the power source for vacuum operation, and vacuum gauge 35 detects the degree of vacuum; vacuum gauge 32 is installed at the pipeline outlet of vacuum pump 33, and vacuum solenoid valve 34 is installed at On the evacuation main pipeline of the vacuum pump 33, the vacuum gauge 35 is connected with the vacuum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com