Micro-control controller

A controller and micro-control technology, applied in functional valve types, engine components, fluid distribution valves, etc., to solve problems such as slow response speed, easy failure of solenoid valves, and short service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

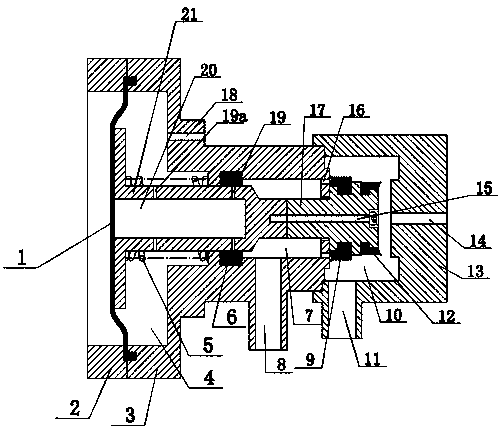

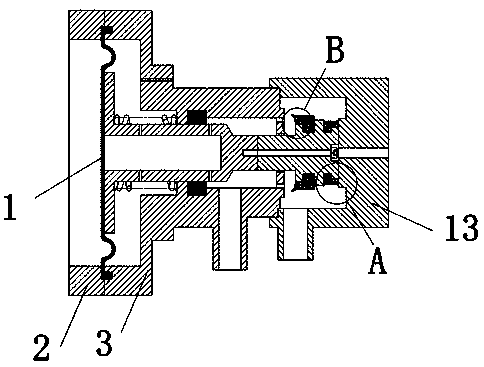

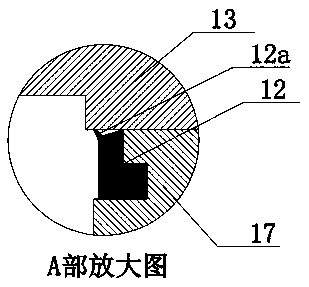

[0013] The present invention will be further described below in conjunction with the accompanying drawings of the description.

[0014] As shown in the figure, the micro-controller is composed of a first housing 2, a second housing 3, and a third housing 13 connected to each other, and an elastic diaphragm 1 is arranged between the first housing 2 and the second housing 3. The first cavity 4, the first housing 2 is provided with the first air channel 18 communicating with the first cavity 4, the first cavity 4 is provided with a hollow T-shaped valve stem 21, and the hollow part of the hollow T-shaped valve stem 21 is Stem cavity 20, a set of front small holes 19a and rear small holes 19 are set on the valve body of the hollow T-shaped valve stem 21, and a valve stem spring 5 is set on the outside of the hollow T-shaped valve stem 21, and the hollow T-shaped valve The tail of the rod 21 is matched with a valve seat 17, and the rear part of the hollow T-shaped valve rod 21, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com