Quick lock splicing assembly system and method

A fast and one-piece technology, applied in the connection of rods, connecting components, mechanical equipment, etc., can solve the problems of wrong assembly direction, assembly, low efficiency, etc., and achieve the effect of high reliability and convenient implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

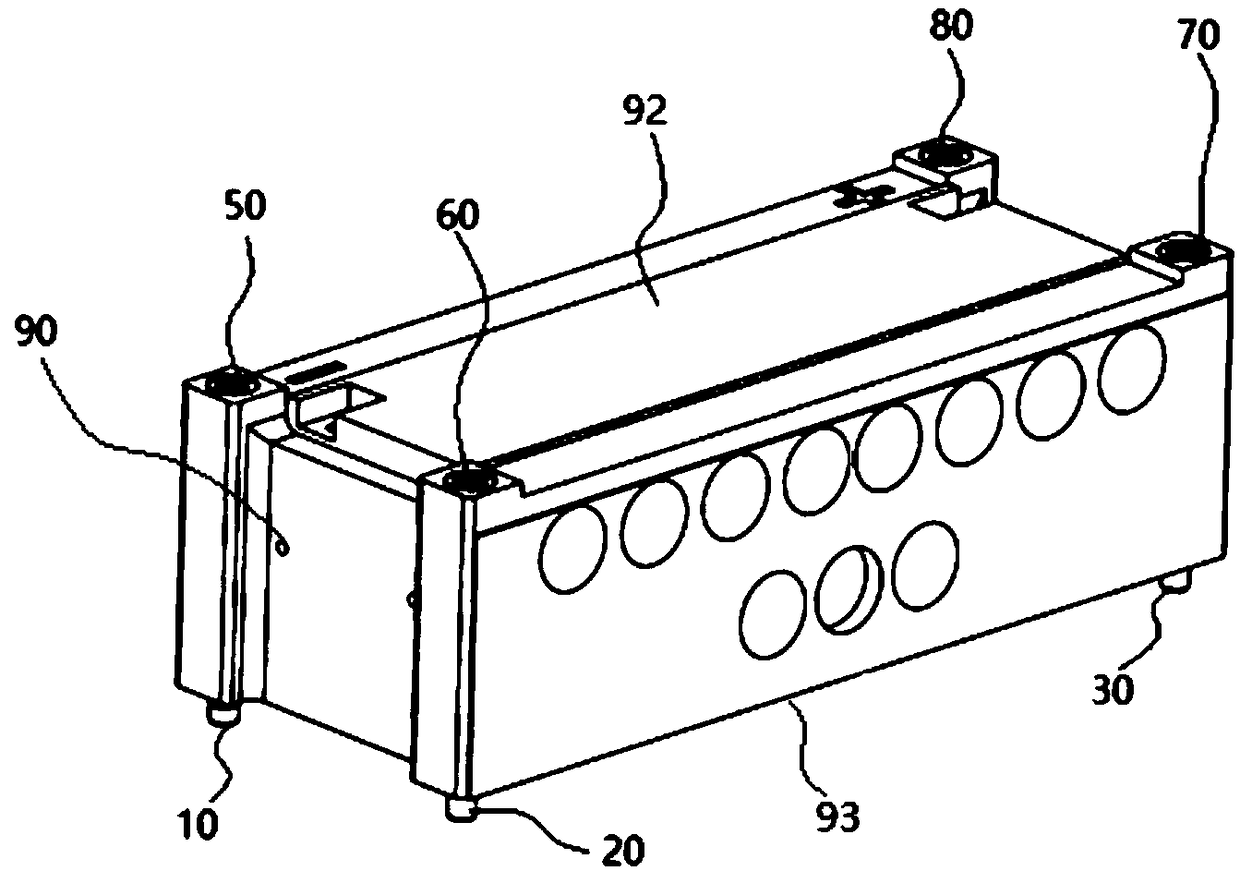

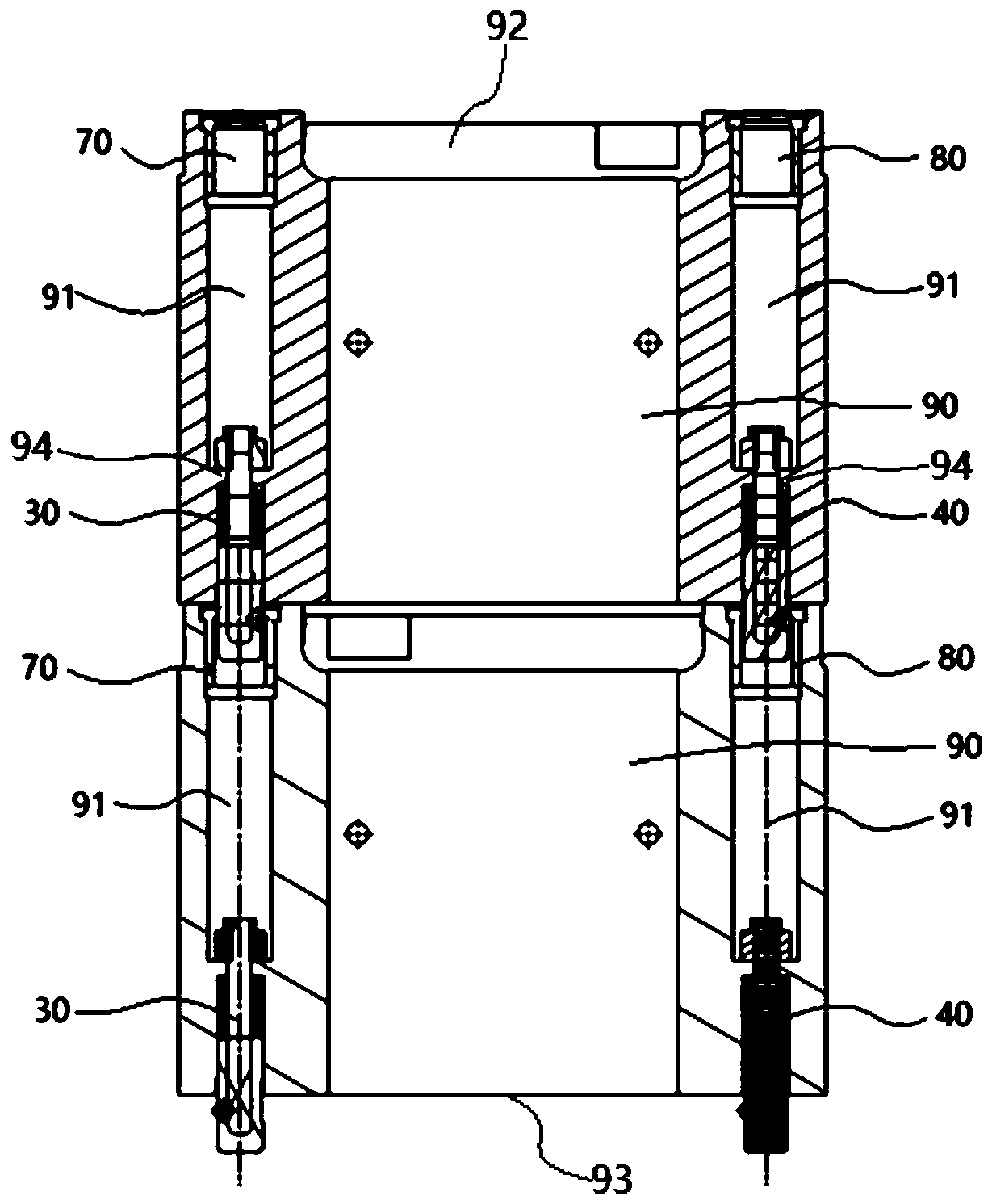

[0044] Aiming at the problem of rapid assembly between components of a modular structure, there is currently no direct and effective solution in the prior art. Therefore, this example provides a brand-new product modular assembly scheme. The product modular assembly scheme sets a group of assembly components on each module structure component, so that any module structure components can pass through the assembly The components are spliced and locked quickly to form the required modular products.

[0045] The components of the modular structure here mainly refer to components with regular overall shape (such as cuboid, cube, etc.), which can be used independently or in combination, such as boxes with various functional components inside.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com