Prefabricated building exterior wall panel drainage structure

A technology for drainage structures and exterior wall panels, applied in building components, building structures, buildings, etc., can solve problems such as the height error between the pipe string and the pipe base, the slow speed of removing moisture and moisture, and the larger gap, etc. Good air flow, avoid cracking or mildew, overcome the effect of pipe wall thickness and installation error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below by means of specific embodiments:

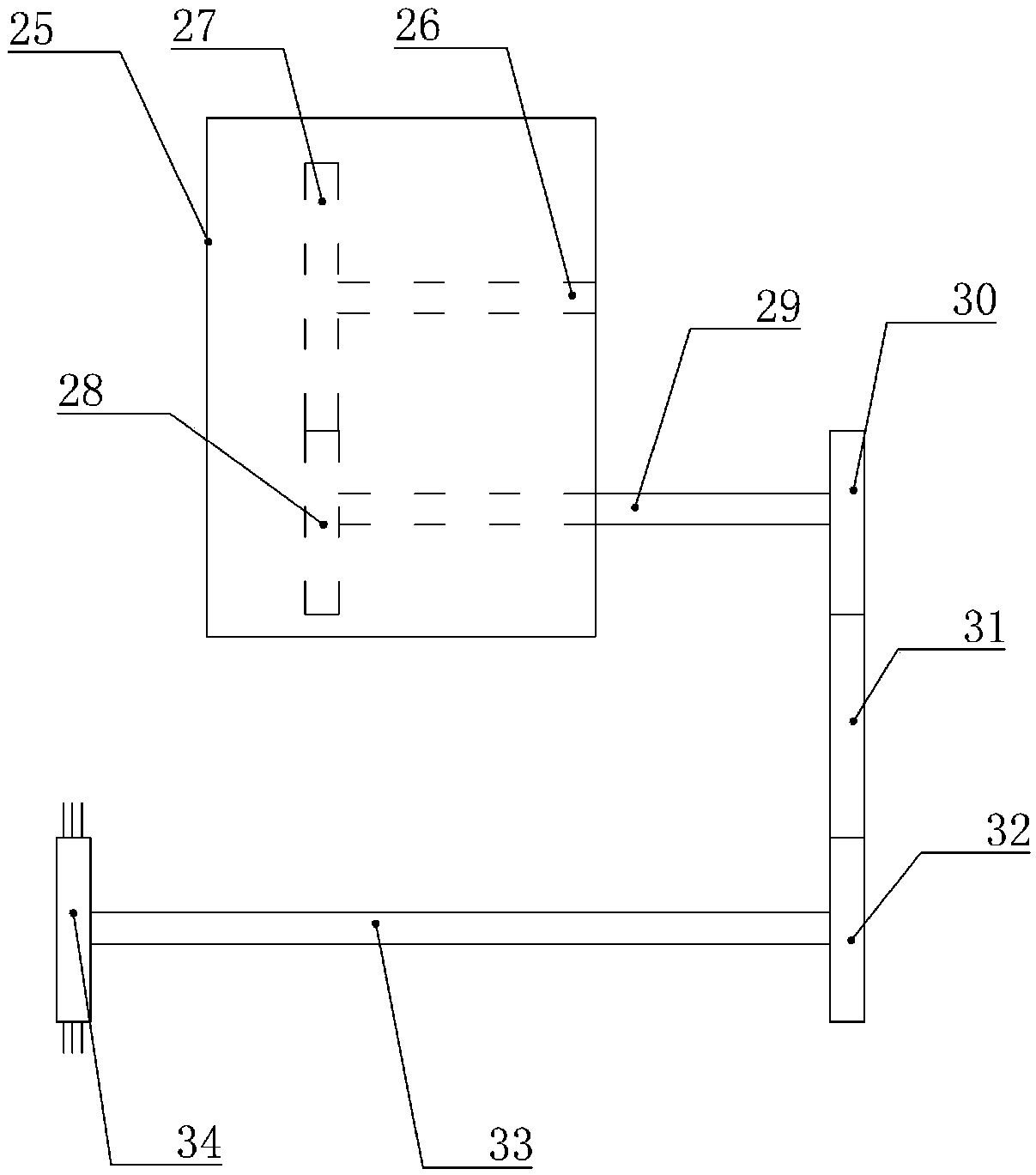

[0020]The reference signs in the drawings of the description include: exterior wall panel 1, interior wall body 2, water guide pipe 3, water guide groove 4, elbow pipe 5, soft water pipe 6, base 7, expansion air bag 8, first section 9, first section Second section 10, trigger switch 11, controller 12, water retaining plate 13, first connecting rod 14, box body 15, cylinder 16, air pump 17, first air pipe 18, piston 19, piston rod 20, spring 21, second Air pipe 22, one-way air outlet valve 23, first support rod 24, housing 25, first rotating shaft 26, first gear 27, second gear 28, second rotating shaft 29, third gear 30, conveyor belt 31, fourth gear 32, the third rotating shaft 33, the impeller 34.

[0021] Example figure 1 and figure 2 Shown: a prefabricated building exterior wall panel drainage structure, including a drainage pipe installed at the bottom of the ver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com