Composite water discharging system of waste mineral oil

A technology of drainage system and waste mineral oil, applied in waterway system, sewage removal, water supply device, etc., can solve the problems of inability to complete the replacement of the filter screen, the drainage system cannot be used immediately, and the blockage of solid materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

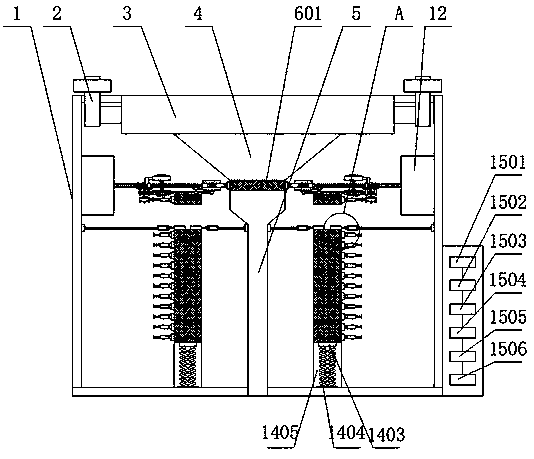

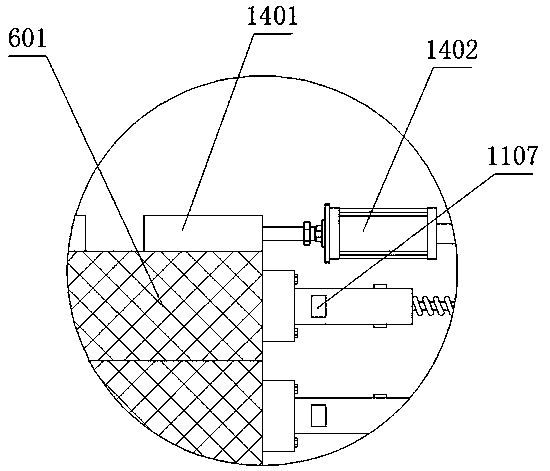

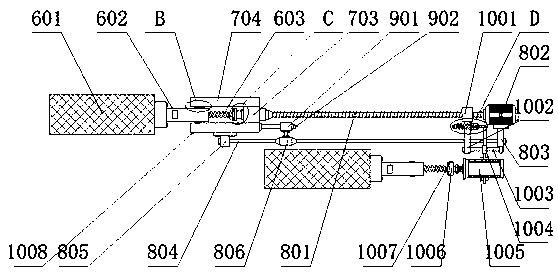

[0038] The specific implementation is as follows: in the process of use, when the waste minerals and oil stains separated from the waste mineral oil enter the sump 3 from the drain pipe 2, they are collected from the sump 3 to the sump 4, and the sump 4 The filter screen 601 on the screen will isolate the solid impurities of the waste mineral oil on its surface. For a long time, the solid impurities with a larger or equal diameter than the through holes of the filter screen 601 will be stuck in the through holes or in the filter screen 601. On the surface, at this time, it is necessary to replace the filter screen 601. When replacing it, the staff first controls the rotation of the motor A802 through the controller 1505, and the rotation of the motor shaft of the motor A802 drives the screw rod connected to it. The rotation of A801 drives the rotation of the screw slider A703 connected to it through the rotation of the screw A801, the movement of the screw slider A703 drives ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com