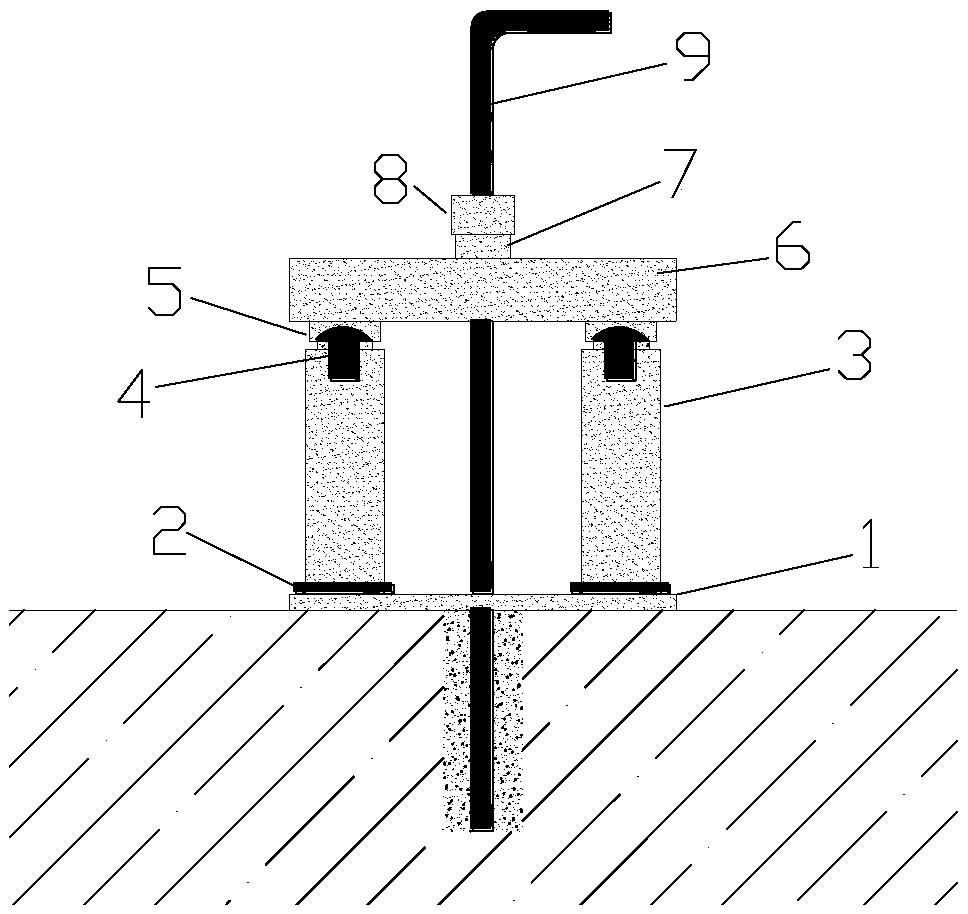

Anti-pulling test device for anchor rod

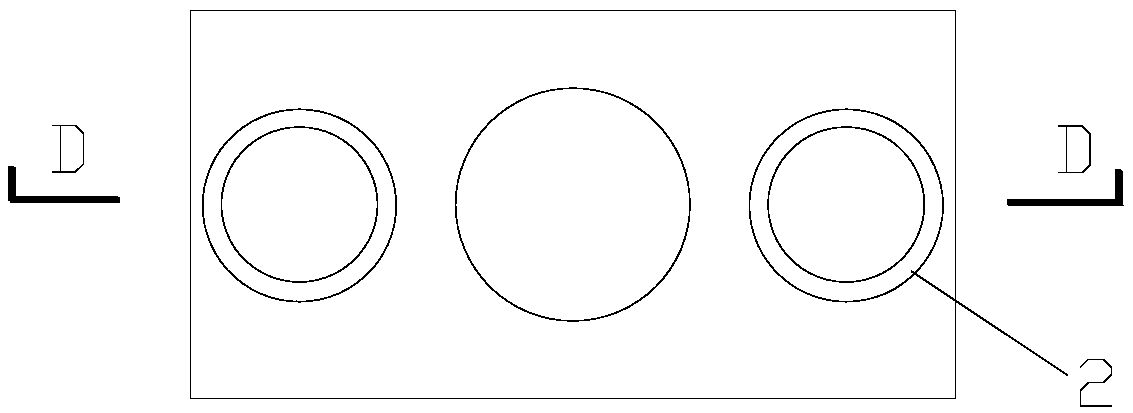

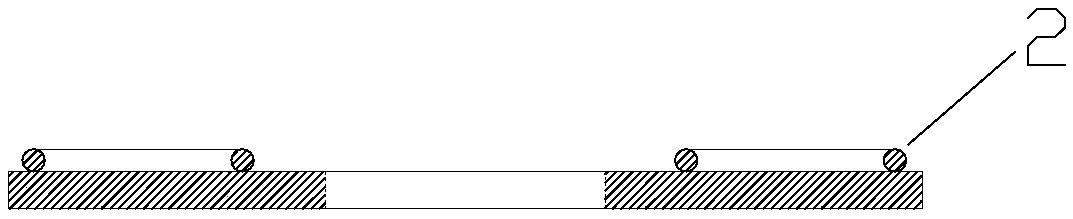

A test device and technology of bolts, which are applied in the test of basic structures, sheet pile walls, buildings, etc., can solve the problems affecting the overall bearing performance of rock bolts, damage to the basic structure of rock bolts, and lack of stable power supply. The effect of light weight, easy transportation, and avoidance of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0106] After the installation of the device is completed, when the core-piercing jack 3 gives an upward force to the pressure-bearing part 6, the pressure-bearing part 6 will have an upward displacement, and the fixed anchor 8 is anchored on the anchor rod 9 above the pressure-bearing part 6, which limits the With the displacement of the pressure piece 6, the pressure bearing piece 6 transmits the force to the anchor rod 9 through the anchorage 8, so as to achieve the effect of applying pull-out force to the anchor rod 9.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com