Stair type expansion reinforcing band system and construction method

An expansion reinforcement belt and stepped technology, applied in artificial islands, water conservancy projects, infrastructure projects, etc., can solve problems such as water seepage in construction joint areas, cracking of super-long components, etc., to speed up construction progress, save engineering costs, and avoid rework The effect of steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

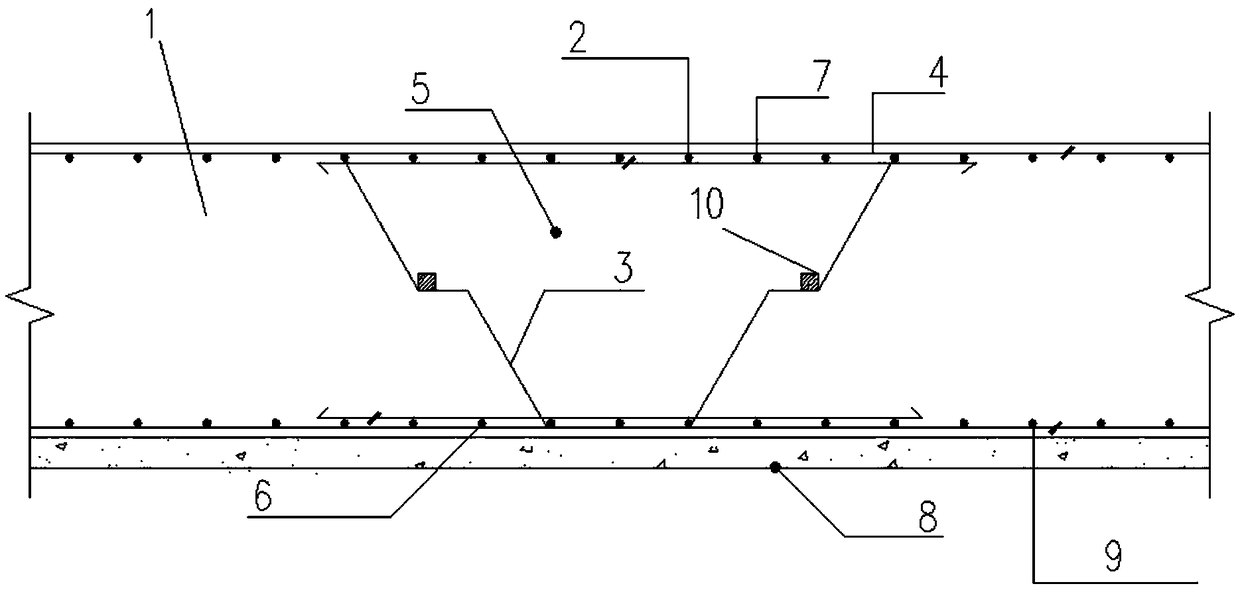

[0037] Such as figure 1 A stepped expansion reinforcing belt system shown includes a concrete bottom form, a concrete matrix is poured on the upper end of the concrete bottom form, and an upper through-going steel bar and a lower through-through steel bar are pre-embedded in the concrete base. An expansion reinforcement belt is provided, and the expansion reinforcement belt is poured with post-poured expansive concrete. The steel wire mesh on both sides is fixedly connected with a stepped vertical reinforcement bar, and the upper and lower ends of the expansion reinforcement belt are respectively provided with an upper additional reinforcement bar and a lower additional reinforcement bar.

[0038] Wherein, the inner corner of the expansion reinforcement belt is provided with an expansion waterstop, the upper additional reinforcement, the lower additional reinforcement, the stepped vertical reinforcement and the steel wire mesh are welded and bound to each other, and the step...

Embodiment 2

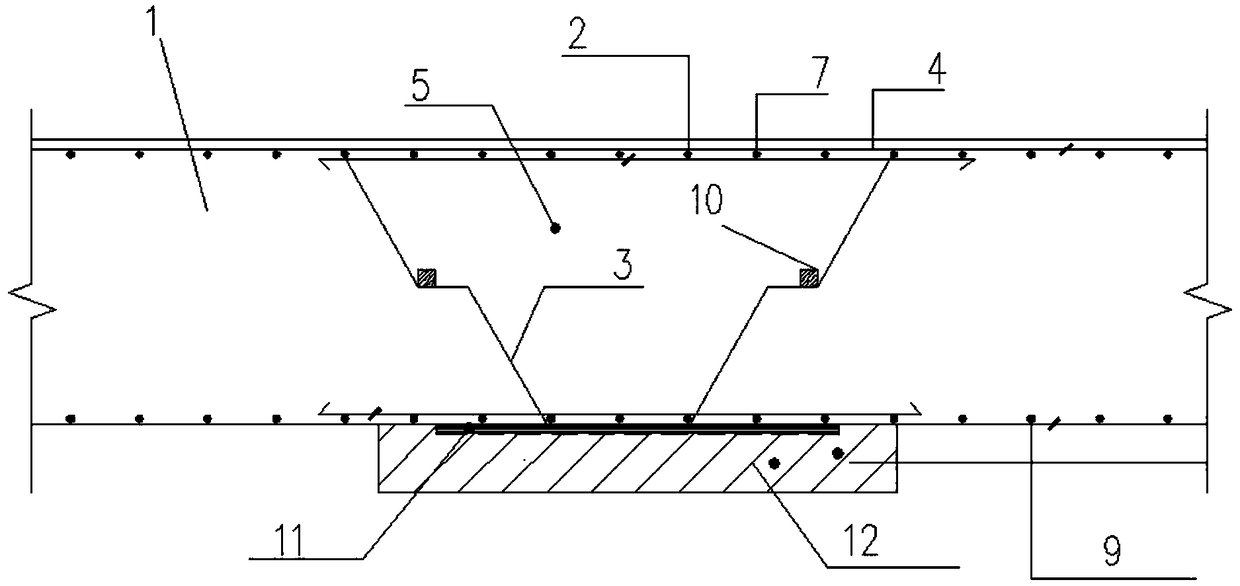

[0047] Such as figure 2 The construction method of the wall expansion reinforcing belt system includes the following steps:

[0048] Step 1, substrate cleaning;

[0049] Step 2: Install expansion reinforcement strips 2 at intervals of 35m along the vertical and horizontal sides of the structure at the parts of the concrete matrix 1 where the temperature shrinkage stress is relatively large. The cross section of the slope is a stepped structure;

[0050] Step 3: Set up a slope stepped steel wire mesh 3 on both sides of the expansion reinforcement belt 2 for isolation, and set a A16@250mm stepped steel bar at the location of the steel wire mesh 3 for reinforcement, and the expansion reinforcement belt 2 Set the upper additional steel bar 7 on the inner side, and weld the additional steel bar 7, the stepped vertical reinforcement bar, and the steel wire mesh 3 to each other, and bind them firmly to avoid being washed away by the concrete during the pouring process. hose 10;

...

Embodiment 3

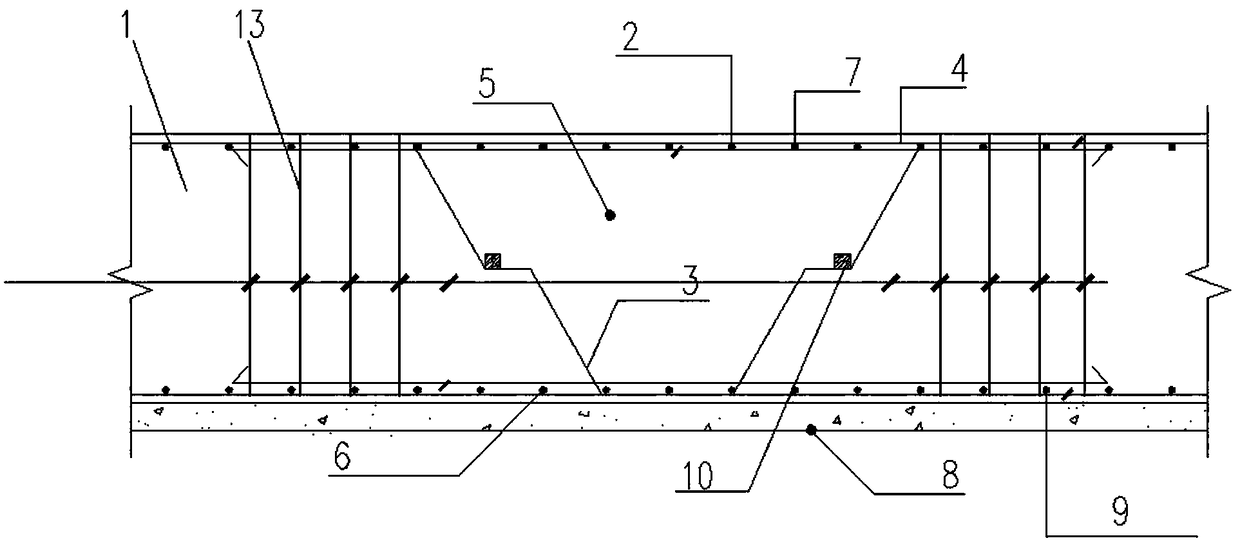

[0055] Such as image 3 The construction method of the beam expansion reinforcement belt system specifically includes the following steps:

[0056] Step 1, substrate cleaning;

[0057] Step 2: Install expansion reinforcement strips 2 at intervals of 35m along the vertical and horizontal sides of the structure at the parts of the concrete matrix 1 where the temperature shrinkage stress is relatively large. The cross section is a slope stepped structure;

[0058] Step 3: Set up a slope stepped steel wire mesh 3 on both sides of the expansion reinforcement belt 2 for isolation, and set a A16@250mm stepped steel bar at the location of the steel wire mesh 3 for reinforcement, and the expansion reinforcement belt 2 The upper additional steel bar 7 is arranged on the inner side, and the additional steel bar 7, the stepped vertical reinforcement bar, and the steel wire mesh 3 are welded to each other and bound firmly. Four stirrup bars 13 are added on both sides of the reinforcement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com