Side-by-side composite colorful short fiber and preparation method thereof

A short fiber and colorful technology, applied in the field of side-by-side composite colorful short fibers and their preparation, can solve problems such as dull color, achieve high color fastness to rubbing and soaping, reduce production costs, The effect of improving usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

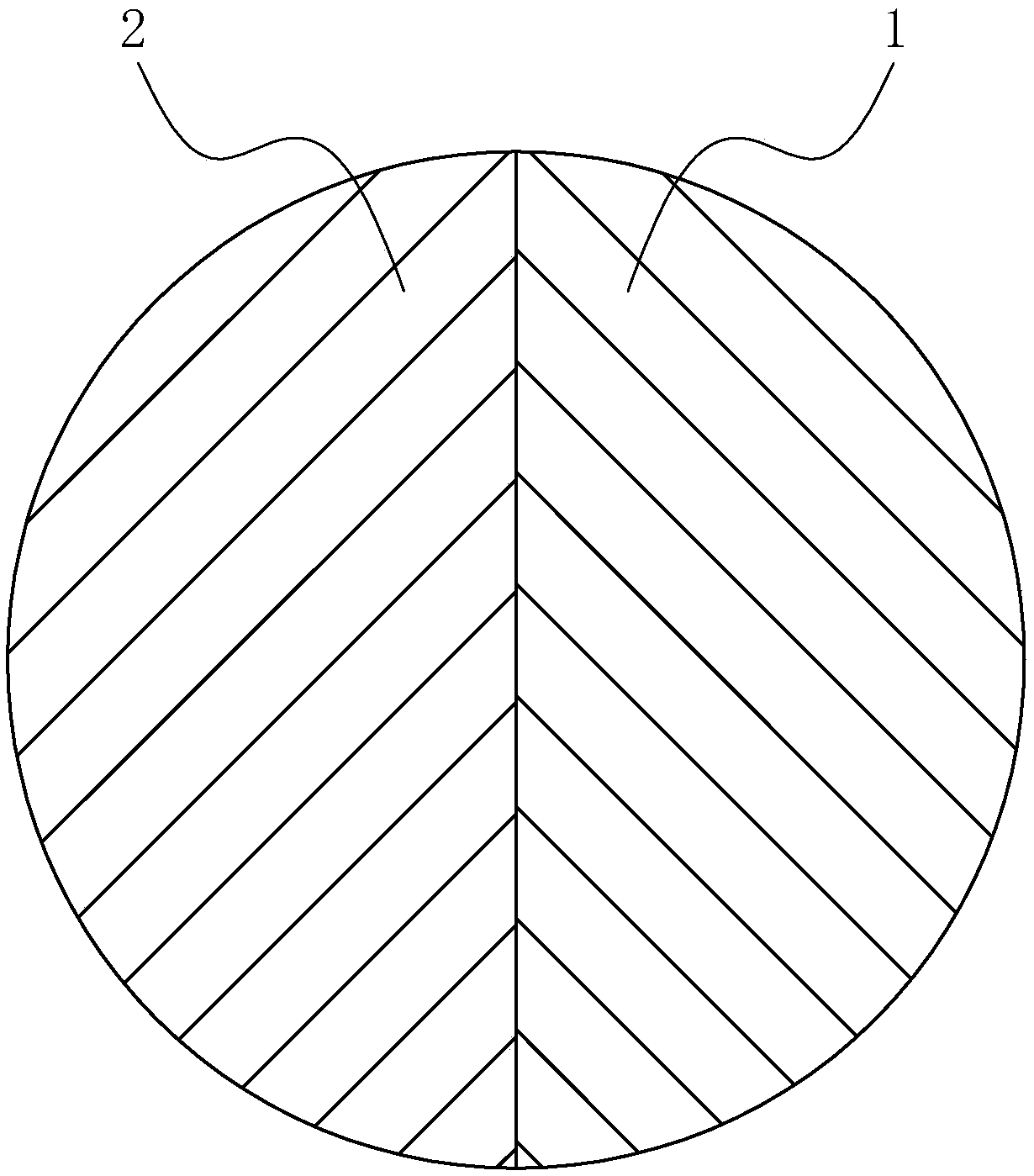

[0043] A kind of juxtaposed composite bright short fiber, such as figure 1 As shown, it includes a first color part with a semicircular cross-section and a second color part with a semicircular cross-section, the cross-sectional radius of the first color part and the cross-sectional radius of the second color part are equal and combined Form a circle. The color of the first color part is a single solid color, the color of the second color part is a single solid color, the color of the first color part is different from the color of the second color part, and the color of the first color part is smaller than the color of the second color part deep.

[0044] The above-mentioned juxtaposed colorful short fibers are prepared by the following method:

[0045] (1) Weigh dimethyl polysiloxane, sucrose benzoate, and 2-ethylhexyl phosphate in a mixer, heat up to 140°C, stir for 20 minutes, mix evenly, and cool to obtain Modifier;

[0046] (2) The polyamide fibers and the modifying ...

Embodiment 2-5

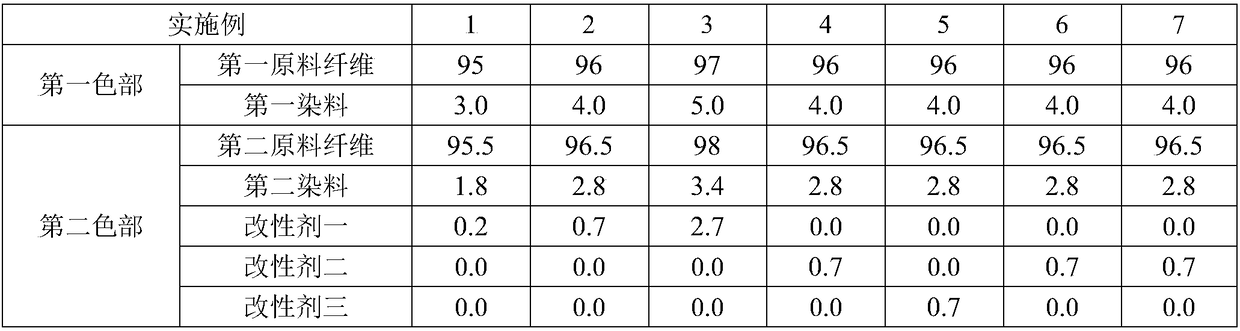

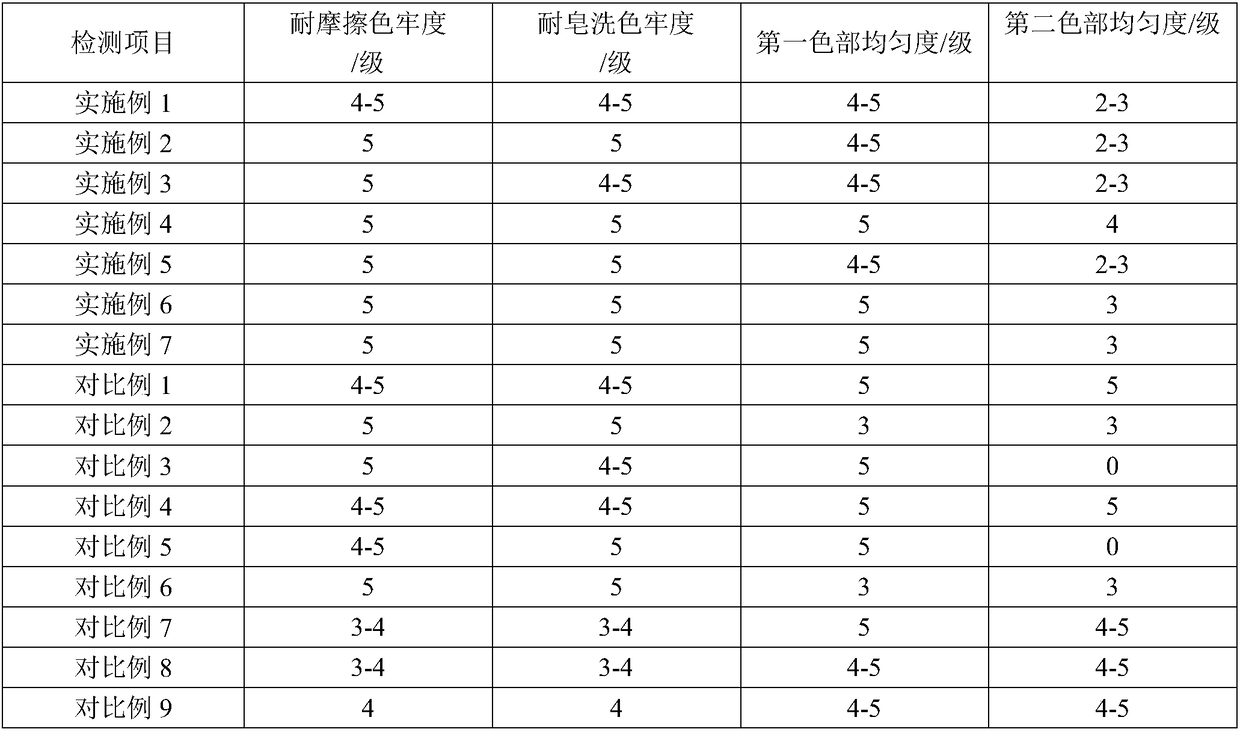

[0052] The difference between Examples 2-5 and Example 1 is that the ratio of raw materials for preparing the side-by-side composite bright short fibers is different, as shown in Table 1 and Table 2.

Embodiment 6

[0054] The difference between Example 6 and Example 4 is that the process conditions and some raw materials for preparing side-by-side composite dazzling short fibers are different; (1) weigh the dimethyl polysiloxane, sucrose benzoate, phosphoric acid- 2-Ethylhexyl ester is placed in a mixer, heated to 145°C, stirred for 20 minutes, mixed evenly, cooled to obtain a modifier;

[0055] (2) The polyurethane fiber and the modifying agent in the step (1) that take weight formula are placed in the mixer, stirred for 15 minutes, and mixed uniformly, thereby obtaining the mixture;

[0056] (3) The polyester fiber is passed through the metering pump and then enters the composite spinning box; at the same time, the mixture in the step (2) is passed through the metering pump and then enters the composite spinning box, and then passes through the parallel composite spinning assembly, at a temperature of 260 ° C. Spinning under the same conditions, and after cooling, drawing, deep drawing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com