Coke oven smoke dust fullytotally-closed scattered collection and centralized treatment method

A technology for centralized treatment and dust collection, which is applied in coking ovens, furnaces to prevent/remove fouling, and the petroleum industry, etc. It can solve problems such as the lack of good control methods for fugitive smoke and dust, and the hazards of the surrounding environment, so as to eliminate potential safety hazards, Improve the effect of dust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

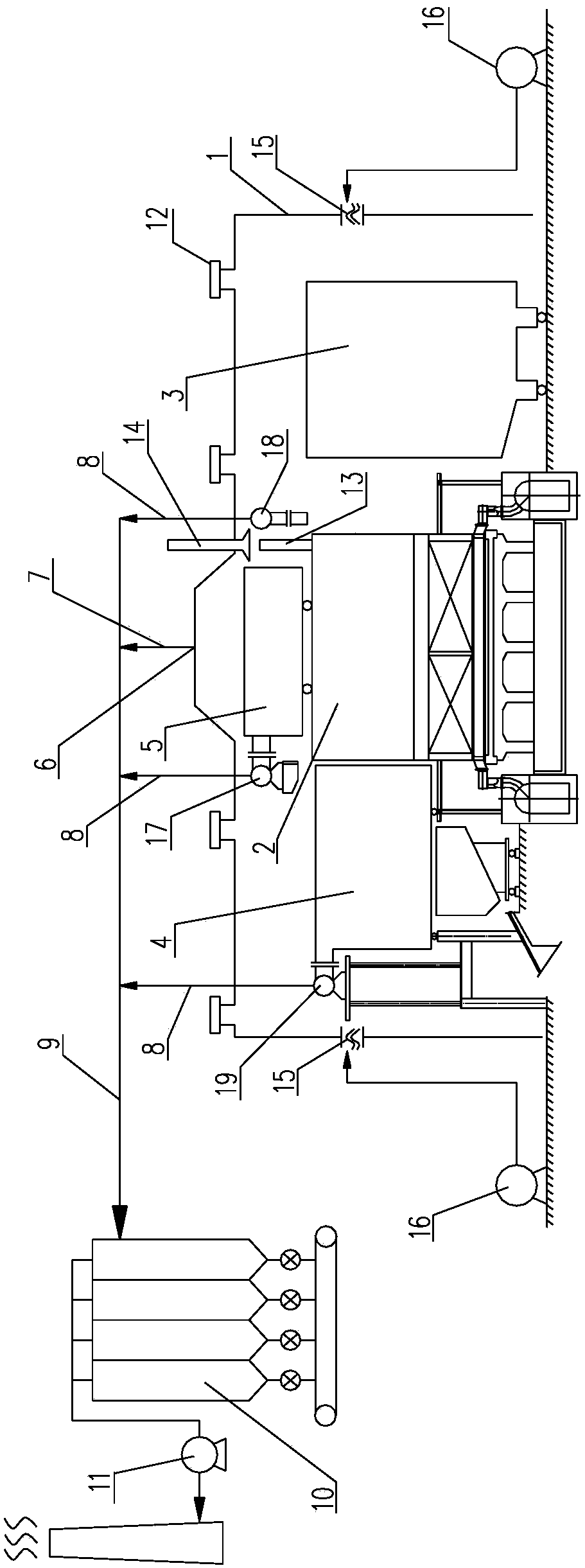

[0025] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0026] like figure 1 As shown in the present invention, a method for fully enclosed scattered collection and centralized treatment of coke oven smoke and dust in the present invention adopts a fully enclosed smoke dust collection hood 1 to completely seal the coke oven 2 and its ancillary facilities. After the fugitive dust collected from the coke oven merges with the smoke and dust in the coal charging dust collection main pipe 17, the coke pushing dust collection main pipe 18 and the coke discharge dust collection main pipe 19, it is transported to the dust removal system through the dust transportation pipeline 9 for centralized treatment .

[0027] The top of the dust collection cover 1 is provided with a plurality of fugitive dust collection ports 6 along the length of the coke oven 2 , and each fugitive dust collection port 6 is connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com