A preparation method of modified graphene oxide flame retardant film and its fire warning application

A flame retardant film, oxide stone technology, applied in fire alarms, alarms, instruments and other directions, can solve the problems of complex preparation process, long warning time, destruction of combustion conditions, etc., achieve simple and efficient preparation technology, shorten warning time, Simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

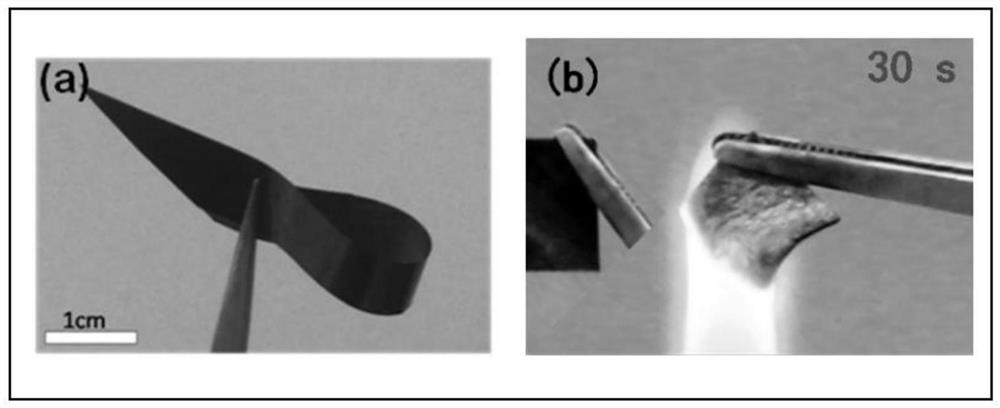

Embodiment 1

[0030] First, take 120mg of graphene oxide to prepare a 5mg / ml uniformly dispersed aqueous solution, then add 12mg of silane coupling agent KH570 (γ-methacryloxypropyltrimethoxysilane), and stir magnetically for 40min-60min to make it Fully disperse evenly, ultrasonically disperse; secondly, discharge air bubbles in a vacuum drying oven for 2-3 times, and discharge air bubbles in the solution; finally, place the treated solution in a petri dish and put it in a vacuum oven at 40°C 12-24h, drying and taking out the modified graphene oxide film. The modified graphene oxide film can be bent to maintain the original mechanical properties, and it has flame retardancy due to the addition of silane coupling agent; but the graphene oxide film only added with silane coupling agent can ℃) The reduction effect is not ideal, and the warning speed has not been improved.

Embodiment 2

[0032] First, take 120mg of graphene oxide to prepare a 5mg / ml uniformly dispersed aqueous solution, then add 12mg of silane coupling agent KH570 (γ-methacryloxypropyltrimethoxysilane) and 12mg of ascorbic acid, and stir magnetically for 40min- 60 minutes to make it fully dispersed, and ultrasonically dispersed; secondly, in the vacuum drying oven, the air bubbles were discharged 2-3 times, and the air bubbles in the solution were discharged; finally, the treated solution was placed in a petri dish and placed at 40 ° C In a vacuum oven for 12-24h, dry and take out the modified graphene oxide film. The modified graphene oxide film can be bent to maintain the original mechanical properties, and it has flame retardancy due to the addition of silane coupling agent; the addition of ascorbic acid makes the modified graphene oxide film ) can be quickly reduced, so as to complete the alarm and play an early warning effect; in the case of ignition, the ascorbic acid-modified graphene o...

Embodiment 3

[0035]First, take 120mg of graphene oxide to prepare a 5mg / ml uniformly dispersed aqueous solution, then add 12mg of silane coupling agent KH570 (γ-methacryloxypropyltrimethoxysilane) and 24mg of ascorbic acid, and stir magnetically for 40min- 60 minutes to make it fully dispersed, and ultrasonically dispersed; secondly, in the vacuum drying oven, the air bubbles were discharged 2-3 times, and the air bubbles in the solution were discharged; finally, the treated solution was placed in a petri dish and placed at 40 ° C In a vacuum oven for 12-24h, dry to obtain a modified graphene oxide film. The modified graphene oxide film can be bent to maintain the original mechanical properties, and it has flame retardancy due to the addition of silane coupling agent; the addition of ascorbic acid makes the modified graphene oxide film ) can be quickly restored, so as to complete the alarm and play an early warning effect; in the case of ignition, the graphene oxide film modified by ascorb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com