Printing ink and preparation technology thereof

A technology for printing ink and vegetable oil, applied in the field of printing, can solve the problems of difficult to control drying speed, inconvenient printing operation, too thin, etc., and achieve the effect of bright colors, moderate drying speed, and not easy to peel off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Embodiment 1: A kind of printing ink, the included components and corresponding parts by weight are shown in Table 1, and are prepared through the following steps:

[0047] Step 1, stirring the oily solvent and the colorant according to the parts by weight;

[0048] Step 2, fully mixing the phenolic resin, curing accelerator, polyethylene wax and the oily solvent obtained in Step 1 according to the parts by weight to form the first mixture;

[0049] Step 3: Add tert-butylhydroquinone to the first mixture obtained in Step 2 according to parts by weight, mix thoroughly, filter to remove impurities, and obtain printing ink.

[0050] Wherein, the vegetable oil is soybean oil; the particle size of the coloring agent is 0.01 μm;

Embodiment 2

[0051] Example 2: a printing ink, the difference from Example 1 is that the components included and their corresponding parts by weight are shown in Table 1.

Embodiment 3-5

[0052] Example 3-5: a printing ink, the difference from Example 1 is that the components included and their corresponding parts by weight are shown in Table 1. During preparation, in step 1, the nano-microcrystalline cellulose colloid, oily solvent, and coloring agent are first stirred and mixed, and then ultrasonically treated; when stirring and mixing, the rotating speed is 300rpm, and the stirring time is 30s; the frequency of ultrasonic emulsification treatment 60kHz, ultrasonic treatment time is 1min. Wherein, the nano-microcrystalline cellulose is spherical, and the nano-microcrystalline cellulose colloid contains 0.01-0.025 wt% of the nano-microcrystalline cellulose, and the rest is ethanol.

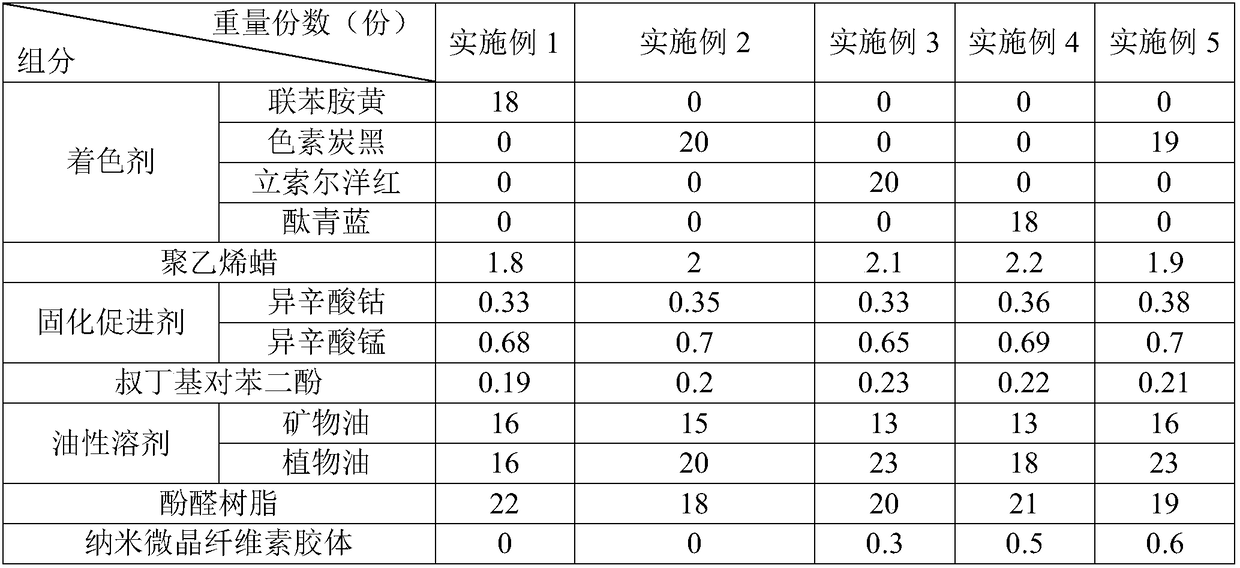

[0053] The components included in Table 1 Embodiment 1-5 and their corresponding parts by weight are shown in Table 1

[0054]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com