Automobile coating and preparation method thereof

A coating and automotive technology, applied in the coating and other directions, can solve the problems of poor stability, tensile and low temperature resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

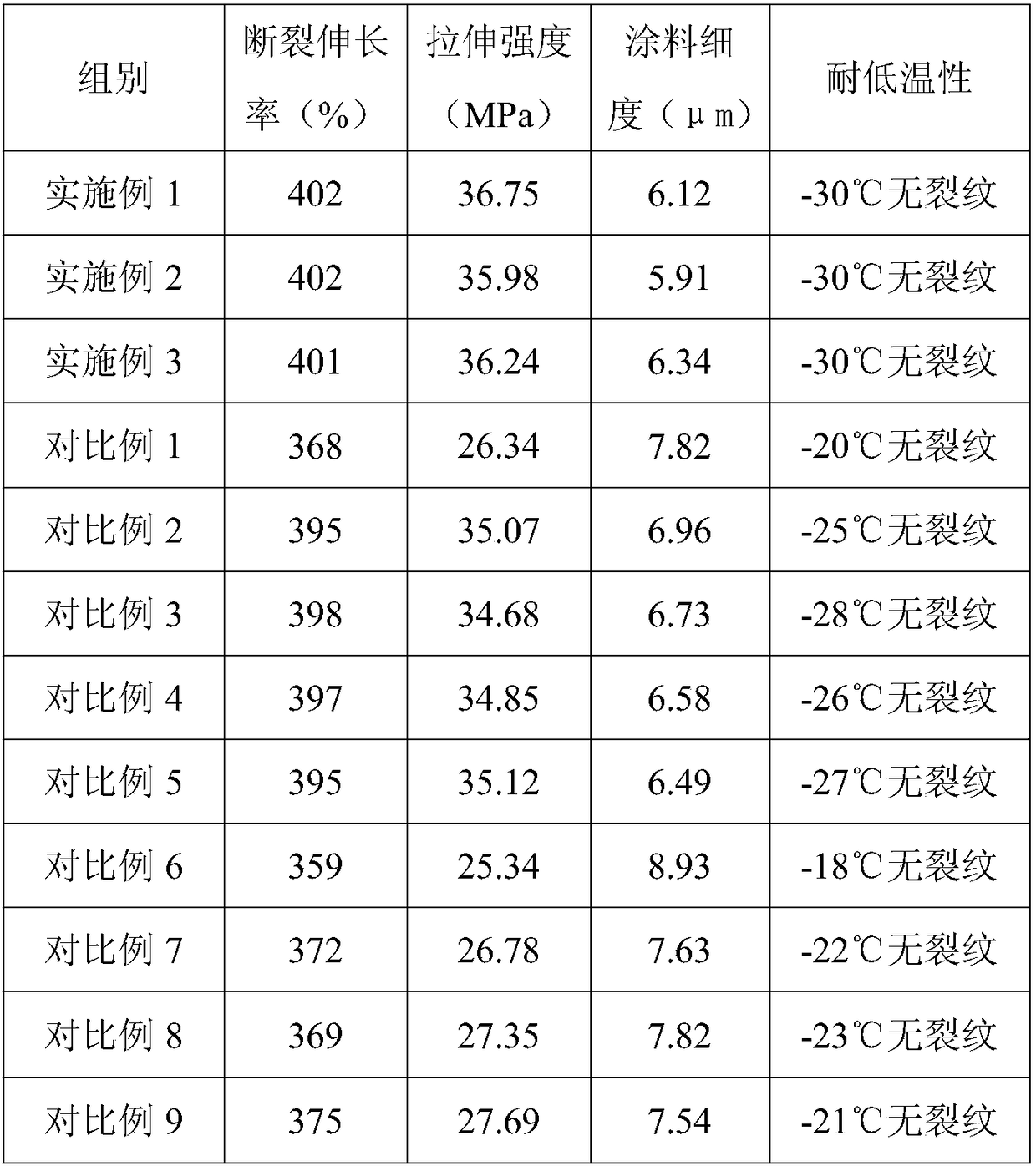

Examples

preparation example Construction

[0033] The preparation method of described automobile paint, comprises the following steps:

[0034]S1: Mix water-based polyurethane resin and methacrylic acid, heat to 75-80°C under stirring, react for 30 minutes, then add polyoxyethylene oleate, react at 75-80°C for 1.5-3 hours, cool down to 50- 55°C, then add triethylamine to react for 15-20min, at the same time cool down to 35-40°C, then add water to disperse, raise the temperature to 50-55°C and react for 30min, remove the solvent in vacuum to obtain the modified waterborne polyurethane resin;

[0035] S2: Stir the modified water-based polyurethane resin, polyaspartic resin, nano-titanium dioxide, titanium dioxide, dispersant, defoamer, and anti-sedimentation agent quickly and evenly, and then slowly add leveling agent and wetting agent under stirring at 1100-1300r / min. The wet agent and ethylene glycol butyl ether are fully stirred and adjusted evenly, and ground in a ball mill for 20-26 hours to 6-10 μm to obtain the ma...

Embodiment 1

[0038] A kind of automobile paint, is made up of main agent and curing agent, and described main agent is by weight, comprises following raw material: polyaspartic resin 30 parts, nano-titanium dioxide 2 parts, waterborne polyurethane resin 40 parts, methacrylic acid 1.4 parts , 0.8 parts of polyoxyethylene oleate, 9 parts of water, 15 parts of titanium dioxide, 0.2 parts of bentonite, 2 parts of dispersant BYK-3332 parts, 0.5 parts of leveling agent BYK-3000, 0.3 parts of defoamer BYK-0930, 0.2 parts of ethanol, 0.3 parts of triethylamine and 4 parts of ethylene glycol butyl ether; the curing agent includes the following raw materials: 14 parts of isocyanate resin and 0.1 part of dibutyltin.

[0039] The preparation method of described automobile paint, comprises the following steps:

[0040] S1: Mix water-based polyurethane resin and methacrylic acid, heat to 80°C under stirring, react for 30 minutes, then add polyoxyethylene oleate, react at 78°C for 3 hours, cool down to 5...

Embodiment 2

[0044] A kind of automobile paint, is made up of main agent and solidifying agent, and described main agent comprises following raw material in parts by weight: 40 parts of polyaspartic resin, 1 part of nano-titanium dioxide, 32 parts of waterborne polyurethane resin, 1 part of methacrylic acid , 0.6 parts of polyoxyethylene oleate, 7 parts of water, 12 parts of titanium dioxide, 0.6 parts of anti-dust wax, 1.5 parts of dispersant BYK-310, 0.3 parts of leveling agent BYK-3010, 0.2 parts of defoaming agent BYK-093, 0.1 parts of propylene glycol part, 0.8 part of triethylamine, and 8 parts of ethylene glycol butyl ether; the curing agent includes the following raw materials: 12 parts of isocyanate resin and 0.6 part of zinc sulfonate.

[0045] The preparation method of described automobile paint, comprises the following steps:

[0046] S1: Mix water-based polyurethane resin and methacrylic acid, heat to 78°C under stirring, react for 30 minutes, then add polyoxyethylene oleate, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com