Heteropolycyle compound having photo-activity and preparation method thereof

A compound and heteropolycyclic technology, applied in the field of photoactive heteropolycyclic compounds and their preparation, can solve the problems of excess low-end products, insufficient application research and development, backward technical level, etc., and achieve convenient sources, low cost, and environmental protection. Friendly and pollution-free effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

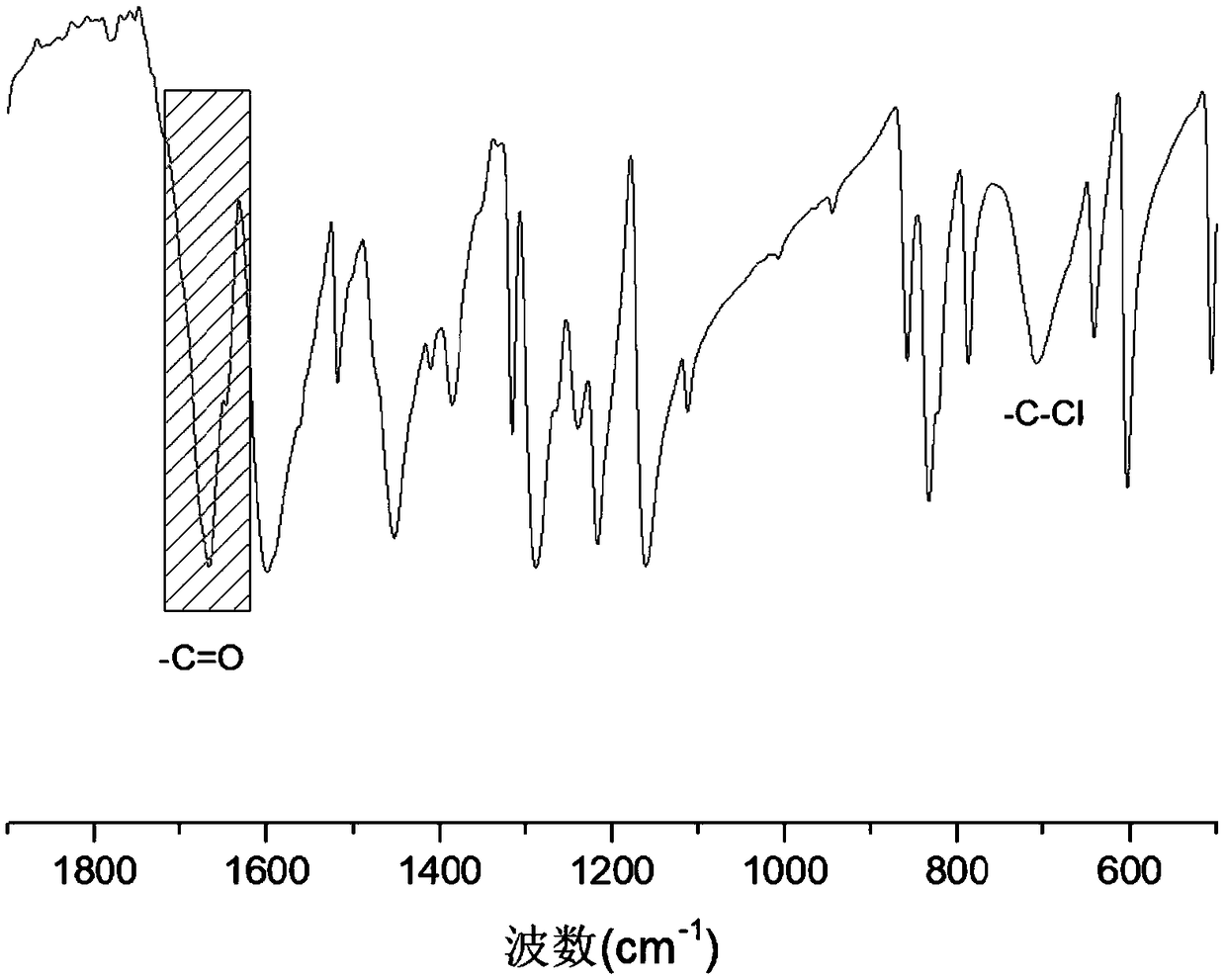

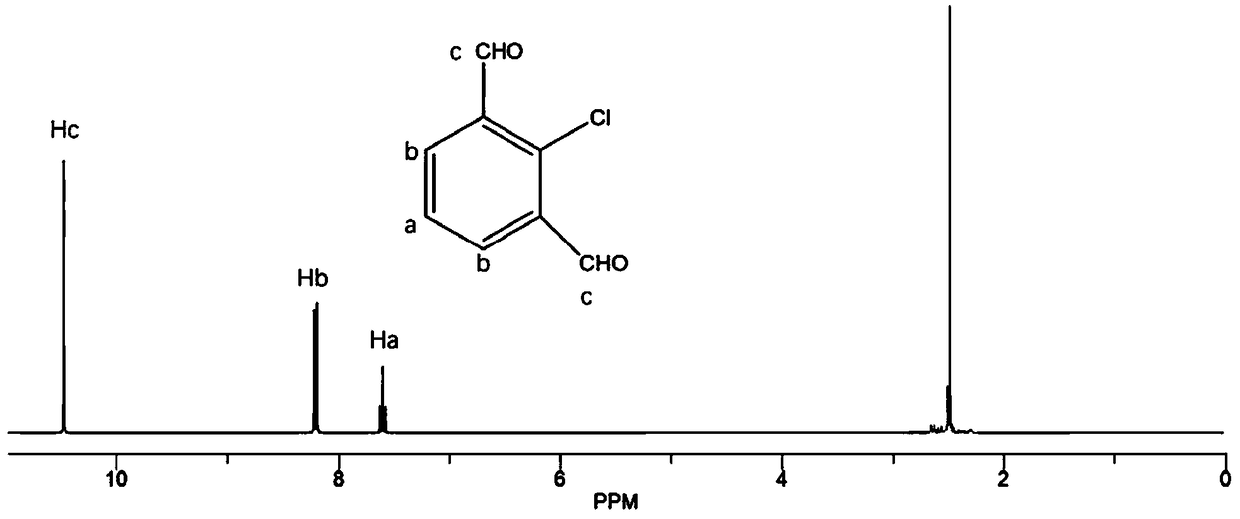

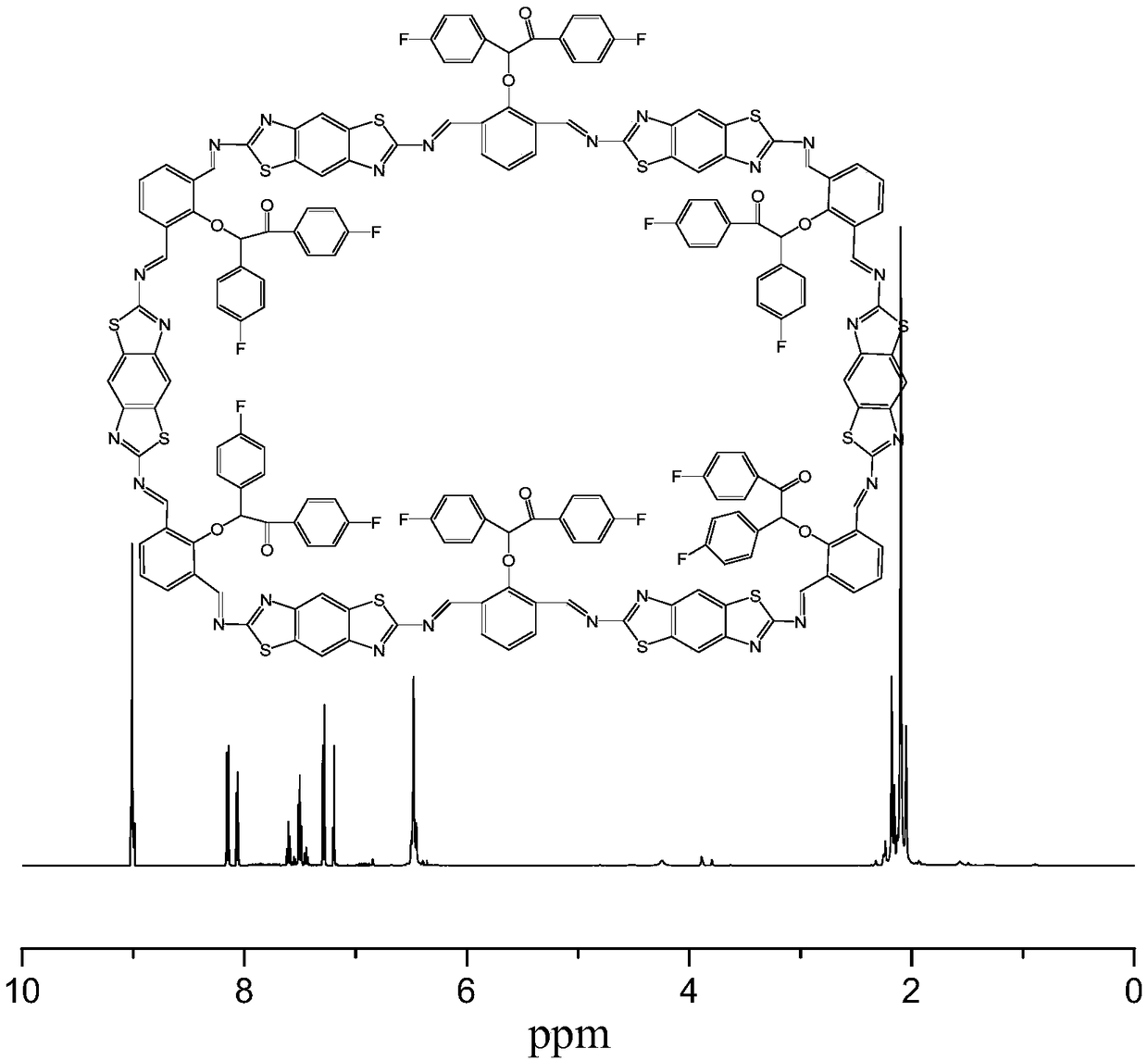

[0038] 1. Preparation of photoactive heteropolycyclic compounds

[0039] (1) 2-chloroisophthalaldehyde and 2,6-diaminobenzodithiazole with a molar ratio of 1:1.1 are added to the reaction vessel, a single solvent mesitylene is added dropwise, the volume of mesitylene and the reaction The volume-to-weight ratio of the total mass of the reactant is 10 milliliters: 1 gram, then add 0.5% acetic acid of the total mass of the reactant, and perform ultrasonic treatment to make it mix uniformly;

[0040] (2) Place the reaction vessel in liquid nitrogen to freeze, vacuumize, seal the opening of the reaction vessel, and react for 3 days at a reaction temperature of 110° C.;

[0041] (3) After the reaction, the solvent was distilled off under reduced pressure, dissolved in dichloromethane, washed 3 times with deionized water, dried overnight with anhydrous sodium sulfate, filtered, rotary evaporated to remove dichloromethane, and vacuum-dried to obtain intermediate product;

[0042] (4...

Embodiment 2

[0049] 1. Preparation of photoactive heteropolycyclic compounds

[0050] (1) 2-chloroisophthalaldehyde and 2,6-diaminobenzobithiazole are added into the reaction vessel with a molar ratio of 1:1.3, and a single solvent 1,4-dioxane is added dropwise, 1, The volume-to-weight ratio of the volume of 4-dioxane to the total mass of the reactant is 8 milliliters: 1 gram, then add hydrochloric acid with 0.8% of the total mass of the reactant, and ultrasonically treat it to make it evenly mixed;

[0051] (2) Place the reaction vessel in liquid nitrogen to freeze, vacuumize, seal the opening of the reaction vessel, and react for 4 days at a reaction temperature of 90° C.;

[0052] (3) After the reaction, the solvent was distilled off under reduced pressure, dissolved in dichloromethane, washed 3 times with deionized water, dried overnight with anhydrous sodium sulfate, filtered, rotary evaporated to remove dichloromethane, and vacuum-dried to obtain intermediate product;

[0053] (4) ...

Embodiment 3

[0060] 1. Preparation of photoactive heteropolycyclic compounds

[0061] (1) 2-chloroisophthalaldehyde and 2,6-diaminobenzodithiazole with a molar ratio of 1:1.5 are added to the reaction vessel, and the volume of mesitylene and 1,4-dioxane is added dropwise A mixed solvent with a ratio of 1:3, the volume-to-weight ratio of the volume of the mixed solvent to the total mass of the reactants is 15 milliliters: 1 gram, then add sulfuric acid with 1% of the total mass of the reactants, and perform ultrasonic treatment to make it evenly mixed;

[0062] (2) Place the reaction vessel in liquid nitrogen to freeze, vacuumize, seal the opening of the reaction vessel, and react for 2 days at a reaction temperature of 135° C.;

[0063] (3) After the reaction, the solvent was distilled off under reduced pressure, dissolved in dichloromethane, washed 3 times with deionized water, dried overnight with anhydrous sodium sulfate, filtered, rotary evaporated to remove dichloromethane, and vacuum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com