Green soil repairing method

A soil remediation, green technology, applied in the field of soil, can solve the problems of restricting sustainable development, damaged soil structure, limited application area, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

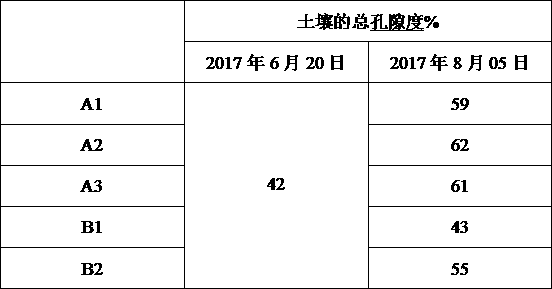

Image

Examples

Embodiment 1

[0026] 1) In the presence of protective gas, calcinate palygorskite PAL, carbon, silver oxide, zinc oxide, praseodymium oxide, cerium oxide, and dysprosium oxide in a weight ratio of 50:13:1:1.8:0.2:0.2:0.2 (The calcination temperature is 360°C, and the calcination time is 7h) to obtain modified PAL powder;

[0027] 2) Under aerobic conditions, ferment livestock and poultry manure, straw, vegetable leaves, rapeseed cake, sugarcane husk, modified PAL powder, Lactobacillus acidophilus, Streptococcus thermophilus, and lactic acid bacteria (livestock and poultry manure, straw , vegetable leaves, rapeseed cake, sugarcane husk, and modified PAL powder in a weight ratio of 50:13:23:10:4:13; in the fermentation system, the concentration of Lactobacillus acidophilus was 140cFU / mg, and the thermophilic chain The concentration of cocci is 130cFU / mg, the concentration of lactic acid bacteria is 90cFU / mg; the ambient temperature of the fermentation is 25°C, and the fermentation time is 70h...

Embodiment 2

[0029] 1) In the presence of protective gas, calcinate palygorskite PAL, carbon, silver oxide, zinc oxide, praseodymium oxide, cerium oxide, and dysprosium oxide in a weight ratio of 50:10:0.8:1.5:0.1:0.1:0.1 (The calcination temperature is 340°C, and the calcination time is 8h) to obtain modified PAL powder;

[0030] 2) Under aerobic conditions, ferment livestock and poultry manure, straw, vegetable leaves, rapeseed cake, sugarcane husk, modified PAL powder, Lactobacillus acidophilus, Streptococcus thermophilus, and lactic acid bacteria (livestock and poultry manure, straw , vegetable leaves, rapeseed cake, sugarcane husk, and modified PAL powder in a weight ratio of 50:10:20:8:2:10; in the fermentation system, the concentration of Lactobacillus acidophilus was 125cFU / mg, and the thermophilic chain The concentration of cocci is 100cFU / mg, the concentration of lactic acid bacteria is 80cFU / mg; the ambient temperature of the fermentation is 15°C, and the fermentation time is 80...

Embodiment 3

[0032] 1) In the presence of protective gas, calcinate palygorskite PAL, carbon, silver oxide, zinc oxide, praseodymium oxide, cerium oxide, and dysprosium oxide in a weight ratio of 50:15:1.2:2:0.3:0.3:0.3 (The calcination temperature is 380°C, and the calcination time is 5h) to obtain modified PAL powder;

[0033] 2) Under aerobic conditions, ferment livestock and poultry manure, straw, vegetable leaves, rapeseed cake, sugarcane husk, modified PAL powder, Lactobacillus acidophilus, Streptococcus thermophilus, and lactic acid bacteria (livestock and poultry manure, straw , vegetable leaves, rapeseed cake, sugarcane husk, and modified PAL powder in a weight ratio of 50:16:25:12:6:16; in the fermentation system, the concentration of Lactobacillus acidophilus was 160cFU / mg, and the thermophilic chain The concentration of cocci is 150cFU / mg, the concentration of lactic acid bacteria is 100cFU / mg; the ambient temperature of the fermentation is 35°C, and the fermentation time is 60...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com