Novel magnesium-based cementing material and magnesium-based cementing material floor preparation method

A magnesia cementitious material and a new type of technology, applied in buildings, building structures, floors, etc., can solve the problems of complex installation and maintenance, high price, easy to mildew and service life, and achieve simple installation and maintenance and improve utilization rate. , the effect of improving physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

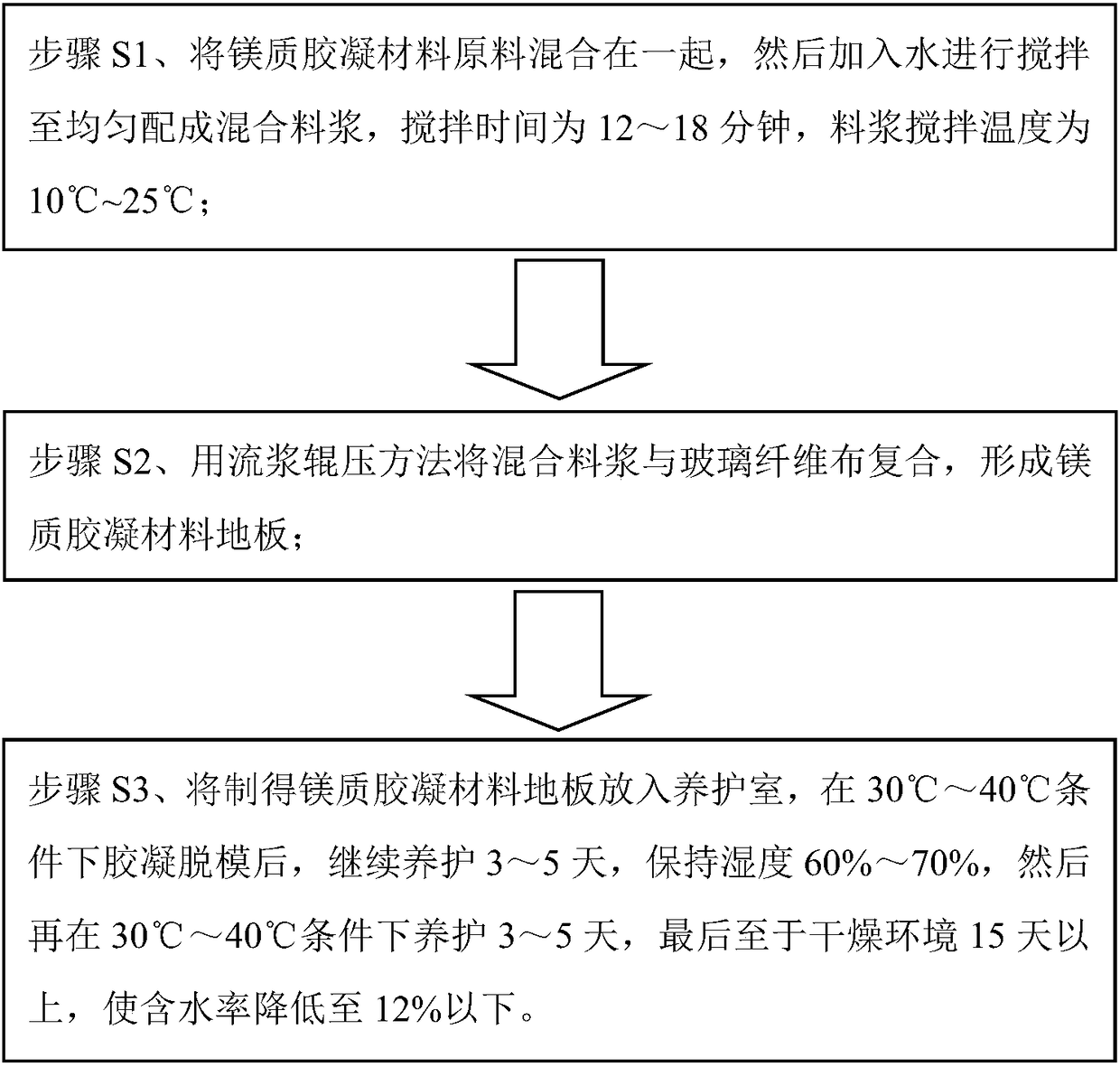

Method used

Image

Examples

Embodiment 1

[0046] Prepare magnesia cemented boards with a thickness of 8mm, use commercially available environmentally friendly adhesives to compound solid wood veneers with a thickness of 2mm, cut and shape according to sales requirements, and make tenons and grooves in double-end milling equipment, and the style is flat buckles.

[0047]According to embodiment 1, the thick 10mm of the magnesia gel floor made, density is 1.2g / cm 3 , dry flexural strength (tested according to 7019-1997 "Fiber Cement Products Test Method", refer to the standard GB25970-2010 "non-combustible inorganic composite board") 22.8mPa, wet flexural strength 21.2mPa, flexural strength softening coefficient is 0.93 (21.2 / 22.8), 24h water absorption thickness expansion rate of 0.2%, formaldehyde emission of 0.1mg / L, surface resistance to cold and heat cycles without cracks and bubbles, non-flammability level is A.

[0048] The magnesia cementitious floor prepared according to Example 1 has the appearance and texture ...

Embodiment 2

[0050] Prepare a 10mm thick magnesia cementitious plate, surface UV printing treatment, cut and shape according to sales requirements, and make tenons and grooves in double-end milling equipment, and the style is a lock.

[0051] The magnesia cementitious floor that makes according to embodiment 2 is thick 10mm, and dry state flexural strength (by 7019-1997 " fiber cement product test method " detects, with reference to standard GB25970-2010 " noncombustible inorganic composite board ") 33.5mPa, wet The flexural strength in the state is 29.5mPa, the softening coefficient is 0.88 (ie 29.5 / 33.5), the 24h water absorption thickness expansion rate is 0.2%, the formaldehyde emission is 0.1mg / L, the surface is resistant to cold and heat cycles without cracks and bubbles, and the non-flammability level is Grade A.

[0052] The magnesia cementitious floor prepared according to Example 2 is printed and decorated, and its appearance and texture can imitate many common decorative materia...

Embodiment 3

[0054] Prepare a magnesia cementitious board with a thickness of 12mm, use commercially available environmentally friendly adhesives to compound PVC materials with a thickness of 2mm, cut and shape according to sales requirements, and make tenons and grooves in double-end milling equipment, and the style is a lock.

[0055] The magnesia cementitious floor that makes according to embodiment 3 is thick 14mm, and density is 1.2g / cm Board") 31.3mPa, wet bending strength 29.5mPa, softening coefficient 0.94 (ie 29.5 / 31.3), 24h water absorption thickness expansion rate 0.2%, formaldehyde emission 0.1mg / L, surface resistance to cold and heat cycles without cracks Bubbling, non-combustibility level is A level. It has the appearance and texture of solid wood flooring, comfortable feet, simple installation and maintenance, greatly improved fire and water resistance, and significantly improved the utilization of wood resources and saved costs.

[0056] The magnesia gelled PVC floor prepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com