Target material packaging method and packaging tool

A packaging method and target technology, which are applied in the directions of transportation and packaging, packaging, special packaging objects, etc., to achieve the effect of reducing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The existing target packaging method is likely to cause the problem of target deformation.

[0032] The reason for the deformation of the target during the vacuum packaging process is analyzed in combination with the structure of a target:

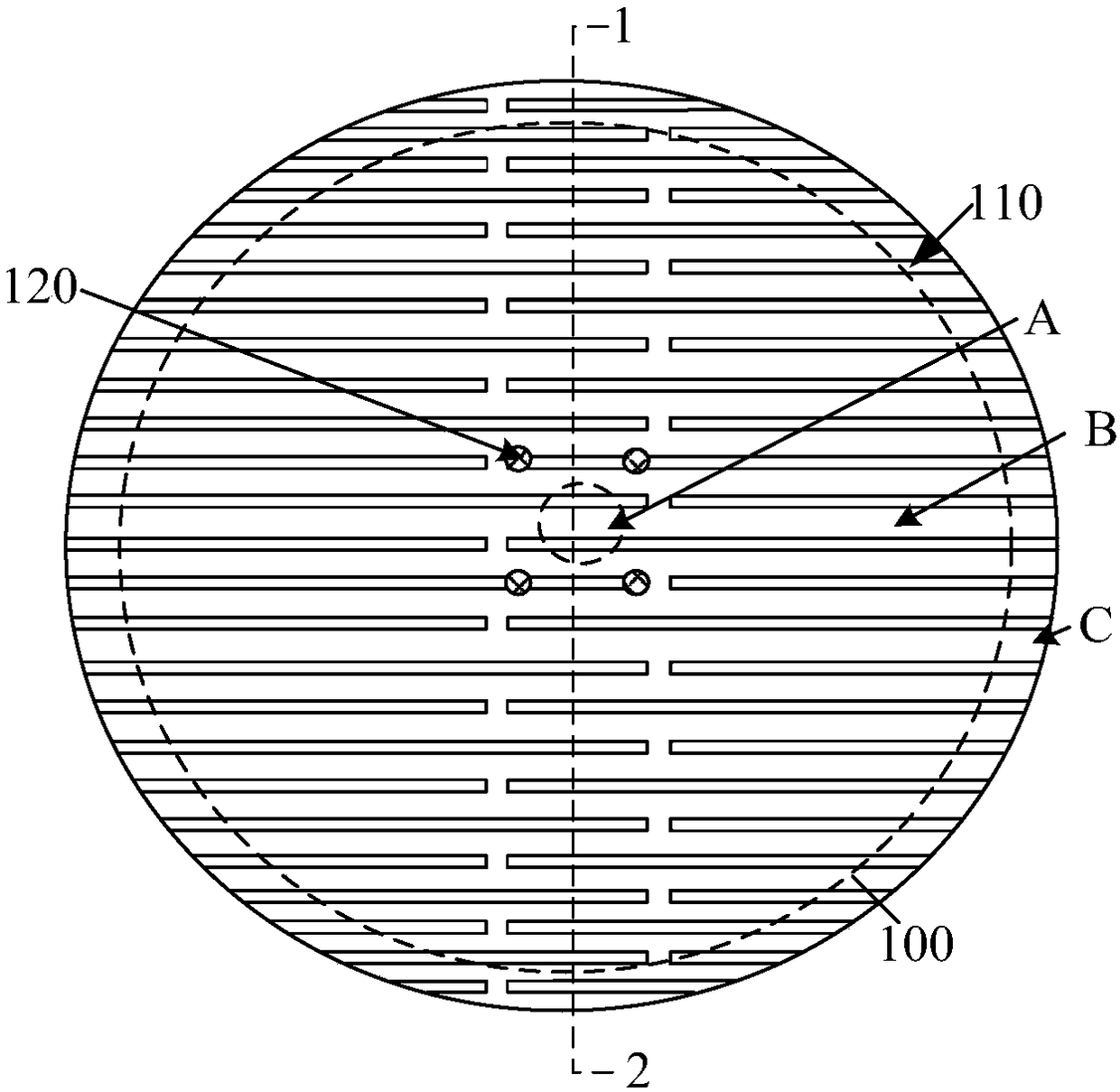

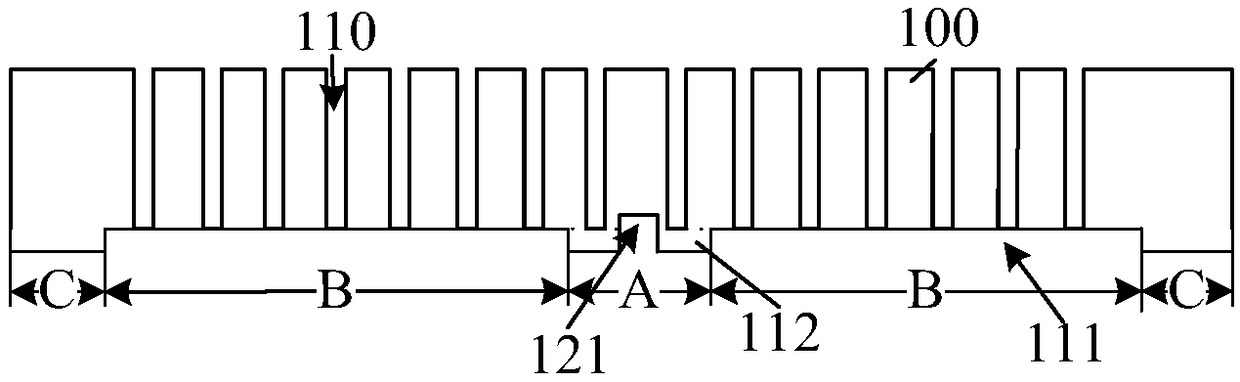

[0033] figure 1 and figure 2 is a schematic diagram of the structure of a target.

[0034] Please refer to figure 1 and figure 2 , figure 2 yes figure 1 Sectional view along cutting line 1-2. The target 100 includes a sputtering surface and a back surface. The target 100 includes a threaded hole area A, a perforated area B surrounding the threaded hole area A, and a support area C surrounding the perforated area B and the threaded hole area A. ; the groove 110 in the target 100 located in the threaded hole area A and the perforated area B; the first protrusion 111 located on the back of the target 100 in the support area C; part 112, and the second convex part has a threaded hole 121 therein.

[0035] Wherein, the groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com