A foam-corrugated composite lattice metal sandwich cone shell and its preparation method

A composite lattice and metal clip technology, applied in the direction of metal layered products, chemical instruments and methods, and other household appliances, to achieve the effects of convenient mass production, high energy absorption efficiency, and broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

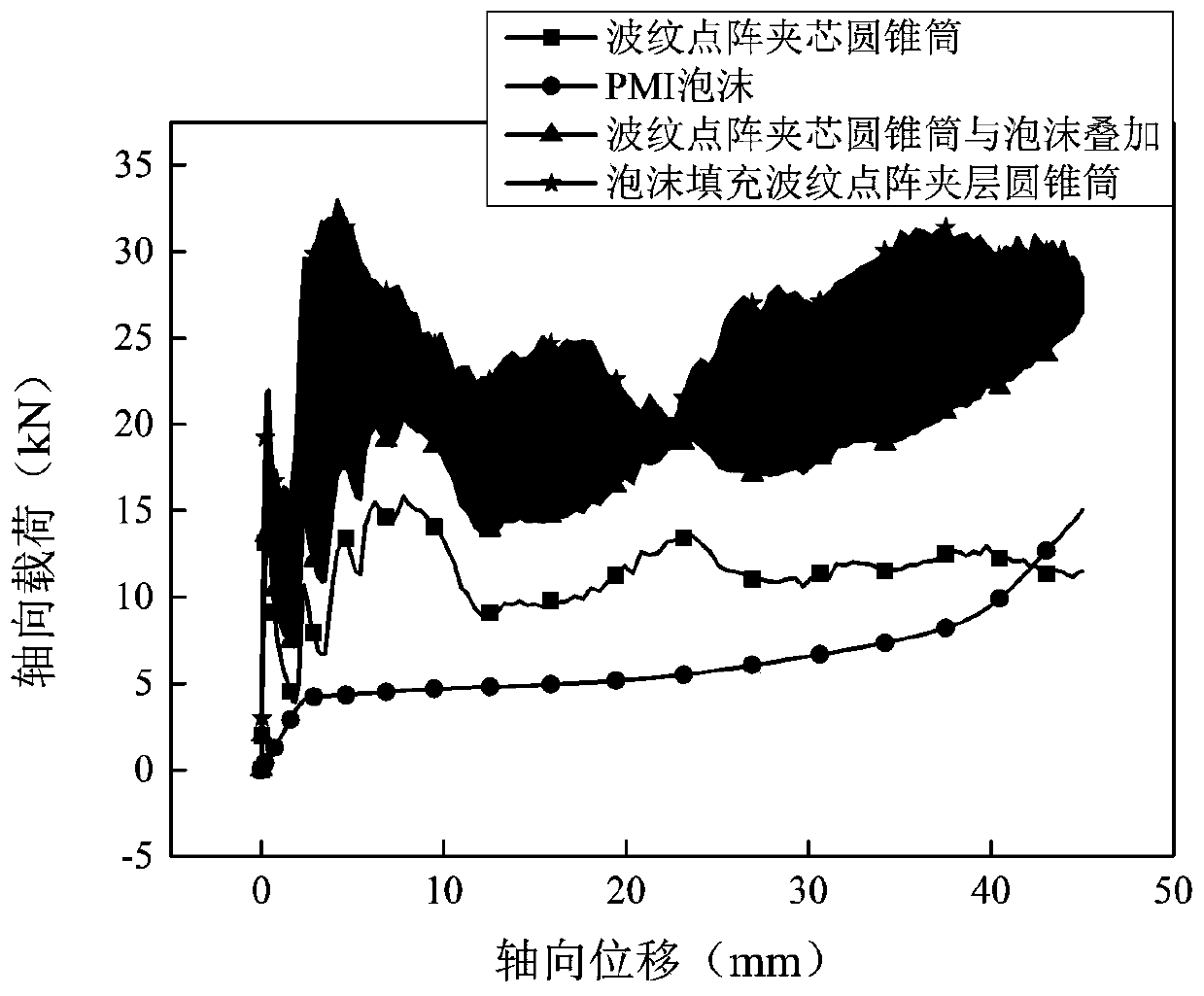

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

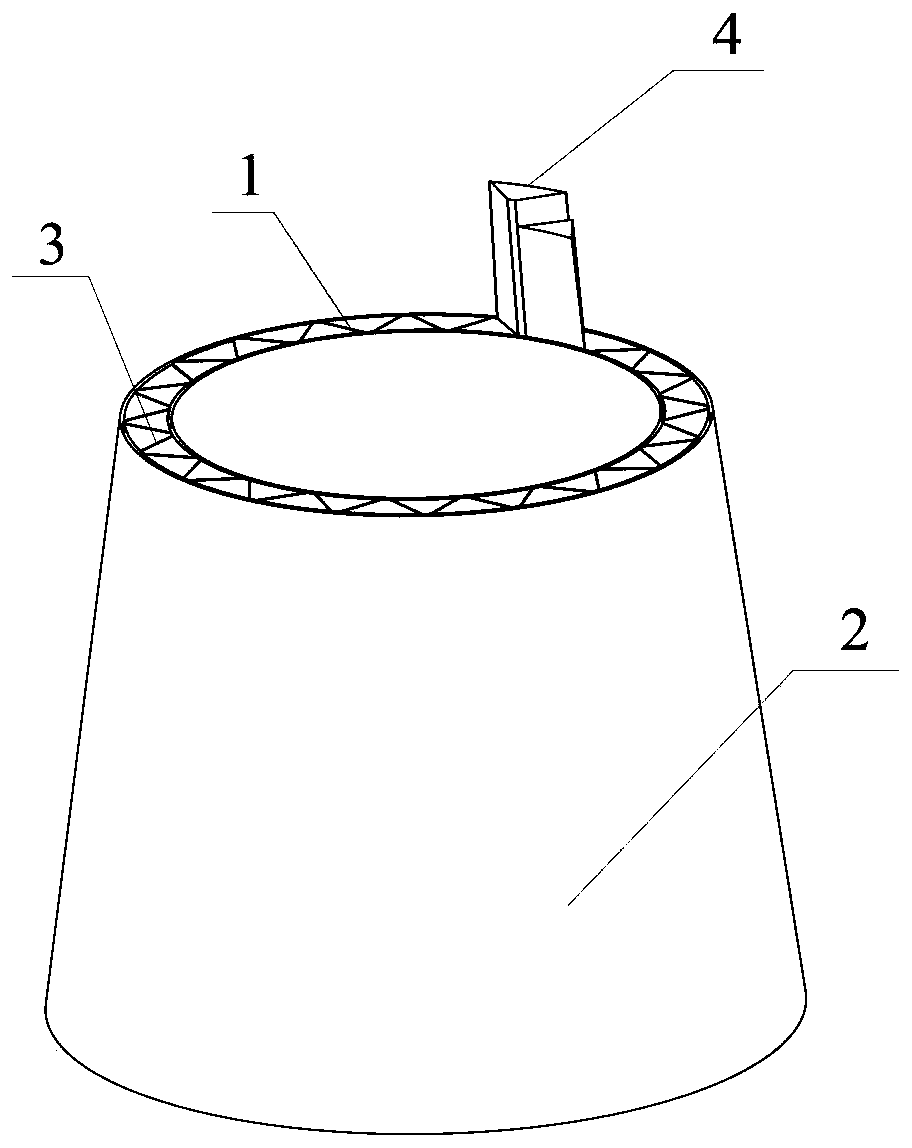

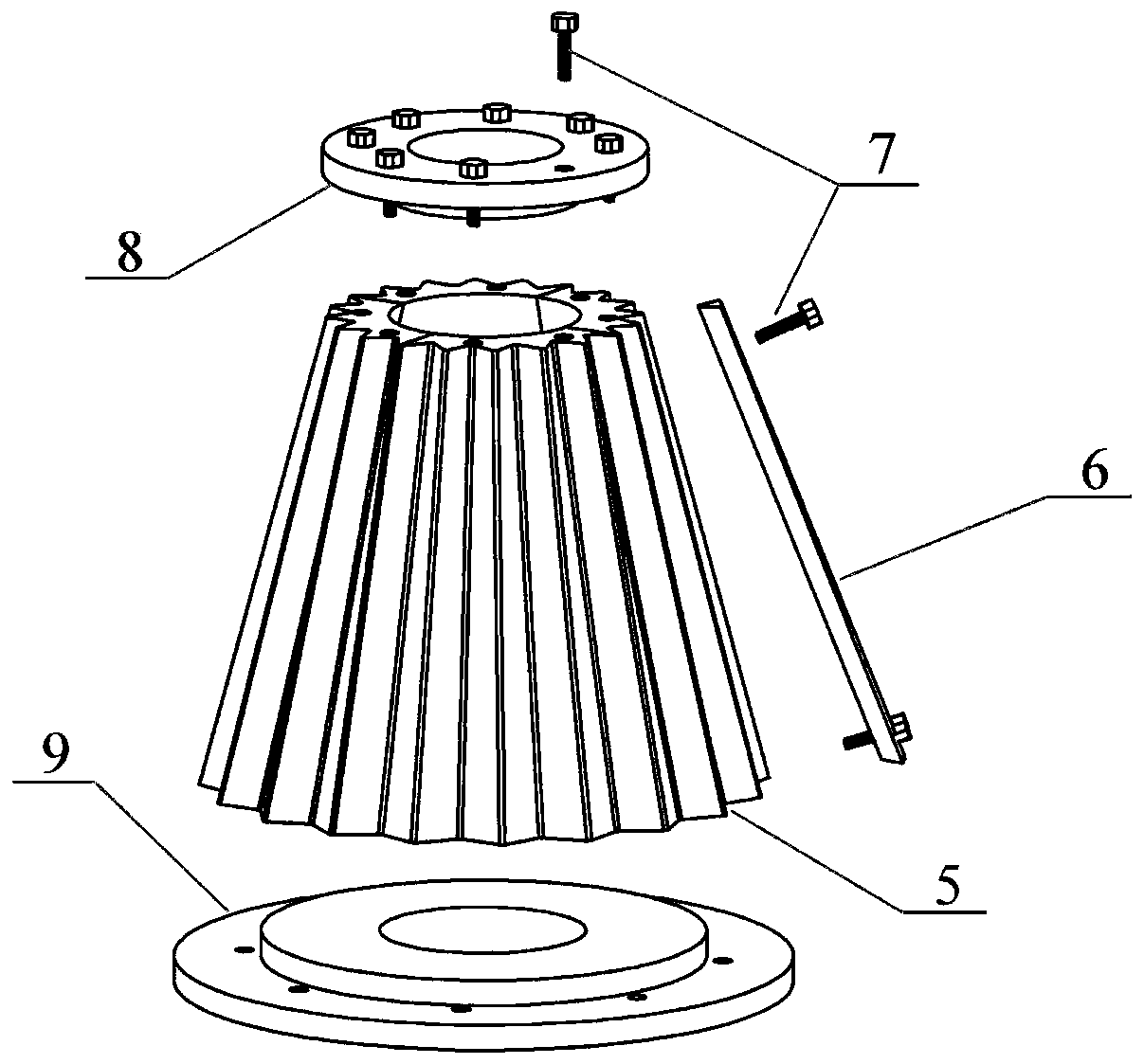

[0028] refer to figure 1 , a foam-corrugated composite lattice metal sandwich conical shell, comprising an inner conical shell 1, an outer conical shell 2, a corrugated core 3 and a foam filling material 4, the corrugated core 3 is a conical metal corrugated structure, which is set inside Between the conical shell 1 and the outer conical shell 2, a foam filling material 4 is arranged in the gap between the corrugated core 3, the inner conical shell 1 and the outer conical shell 2, the inner conical shell 1, the outer conical shell 2, and the corrugated core 3 is connected with the foam filling material 4 to form a foam-corrugated composite lattice metal sandwich cone shell.

[0029] The corrugated unit cells in the corrugated core 3 have the same geometric shape along the circumferential direction and are uniformly distributed, and have taper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com