Surface double-layer polishing equipment for building wood processing

A wood, double-layer technology, applied in the field of wood, can solve the problems of low processing speed, rough surface of the board, increase the workload of workers, etc., and achieve the effect of not easy to shake and easy to pick and place.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

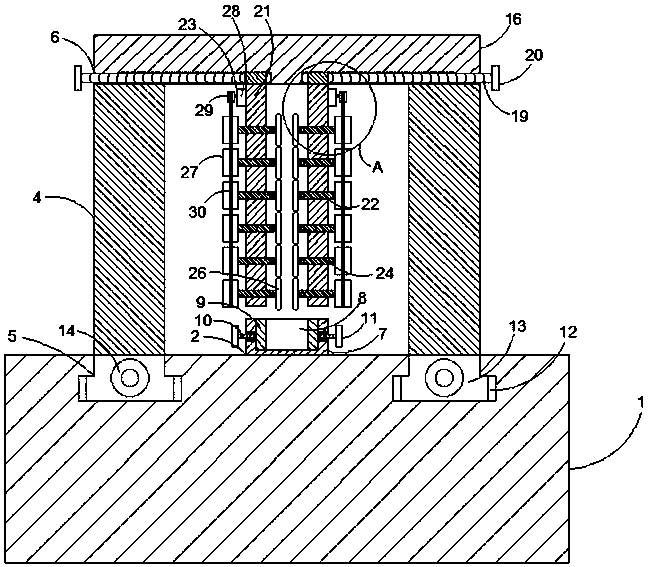

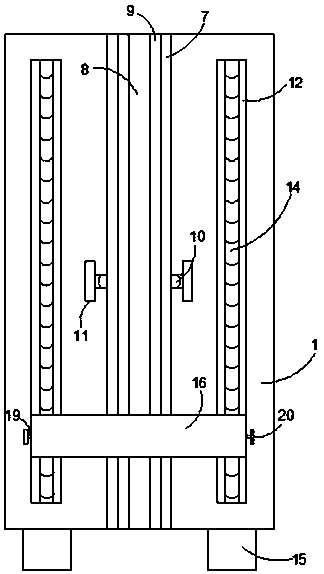

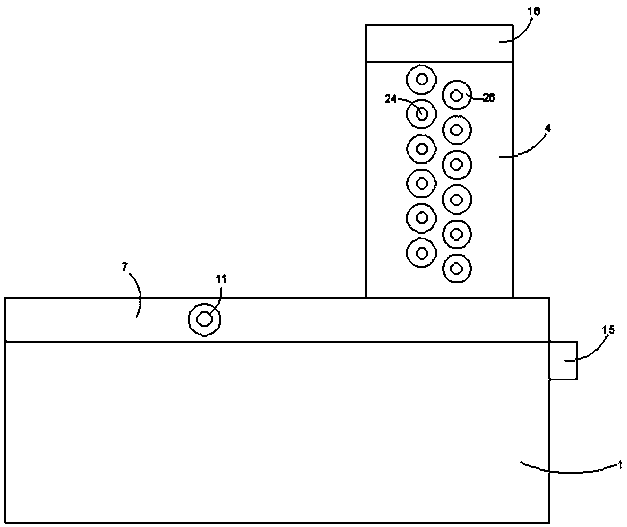

[0026] like Figure 1-4 As shown, a surface double-layer polishing device for building wood processing includes a body 1, the upper end of the body 1 is fixedly connected with a feeding mechanism 2, and the feeding mechanism 2 includes a fixed block 7 fixedly connected to the upper end of the body 1, and the fixed block 7 The length matches the body 1, the fixed block 7 is set close to the center of the body 1, the upper end of the fixed block 7 is provided with a feeding trough 8 that runs through front and back, and the inner walls of the left and right ends of the feeding chute 8 are provided with matching The opposite side walls of the two splints 9 are fixedly connected with a wave-shaped rubber layer, and the opposite side walls of the two splints 9 are connected with a first threaded rod 10 in rotation, and the first threaded rod 10 is far away from the splint 9 One end of the thread runs through the inner wall of the feeding trough 8 and extends to the outside, and one...

Embodiment 2

[0033] refer to Figure 5-6 The difference between this embodiment and Embodiment 1 is that two air pumps 31 are fixedly connected to the fixed plate 21, and the two air pumps 31 are respectively located on the front and rear sides of the polishing wheel 26, and the air outlet end of the air pump 31 is fixedly connected with an air pump 31. The nozzle 32 and the gas nozzle 32 are elongated, and the moving direction of the gas nozzle 32 and the fixed plate 21 is always at an angle of 90 degrees.

[0034] Compared with Embodiment 1, the advantage of this embodiment is that when a plurality of polishing wheels 26 are polishing the surface of the wooden board to be processed, if the surface of the wooden board to be processed is not clean, it is easy to cause damage to the polishing wheel 26 during the polishing process. , reduce its service life, and there is too much dust on its surface to also affect the quality of its polishing. The air pump 31 blows the wind on the surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com