A preparation method of HK30 material based on MIM molding and HK30 blade

A hk30-ti, feeding technology, applied in the field of powder metallurgy, can solve the problems of over-burning and under-burning, and achieve the effect of increasing the sintering temperature, widening the sintering window, and improving the yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

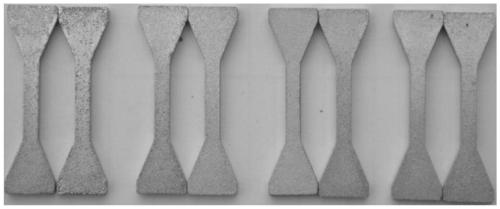

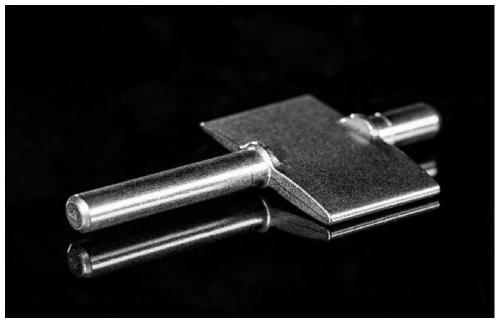

[0030] A method for preparing HK30 material based on MIM molding, comprising the following steps:

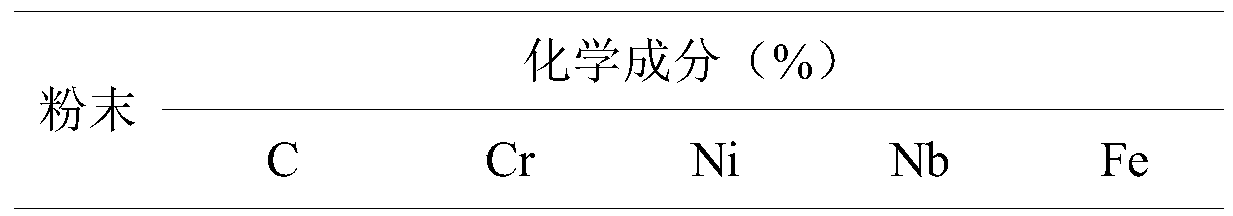

[0031] (1) Mix HK30 stainless steel powder and hydrogenated dehydrogenation titanium powder with a four-pot mixer for 5 hours to obtain HK30-Ti composite powder; wherein, the median particle size of HK30 stainless steel powder is 20 μm, and the median particle size of hydrogenated dehydrogenation titanium powder is The particle size is 17 μm; the amount of hydrogenated dehydrogenation titanium powder accounts for 1.2% of the total amount of HK30-Ti composite powder; the composition of HK30 stainless steel powder and titanium powder is shown in Table 1 and Table 2 below;

[0032] (2) After mixing the HK30-Ti composite powder obtained in step (1) with the binder, knead, and then granulate to obtain granular feed; wherein, the amount of binder is controlled as the loading of the HK30-Ti composite powder 57% of the amount, the mixing temperature is 155°C, and the mixing time is 180m...

Embodiment 2

[0042] A method for preparing HK30 material based on MIM molding, comprising the following steps:

[0043] (1) Mix HK30 stainless steel powder and hydrogenated dehydrogenation titanium powder with a four-pot mixer for 5 hours to obtain HK30-Ti composite powder; wherein, the median particle size of HK30 stainless steel powder is 20 μm, and the median particle size of hydrogenated dehydrogenation titanium powder is The particle size is 17 μm; the amount of hydrogenated dehydrogenation titanium powder accounts for 0.4% of the total amount of HK30-Ti composite powder; the composition of HK30 stainless steel powder and titanium powder is the same as in Example 1;

[0044](2) After mixing the HK30-Ti composite powder obtained in step (1) with the binder, knead, and then granulate to obtain granular feed; wherein, the amount of binder is controlled as the loading of the HK30-Ti composite powder 57% of the amount, the mixing temperature is 155°C, and the mixing time is 180min;

[004...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com