An environmentally friendly processing technology to replace phosphorus saponification treatment on bearing surface

A technology of bearing surface and processing technology, which is applied in the direction of engine components, mechanical equipment, etc., can solve the problems of phosphorus saponification treatment of environmental pollution, achieve zero pollution discharge, improve adsorption capacity, and simplify the treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

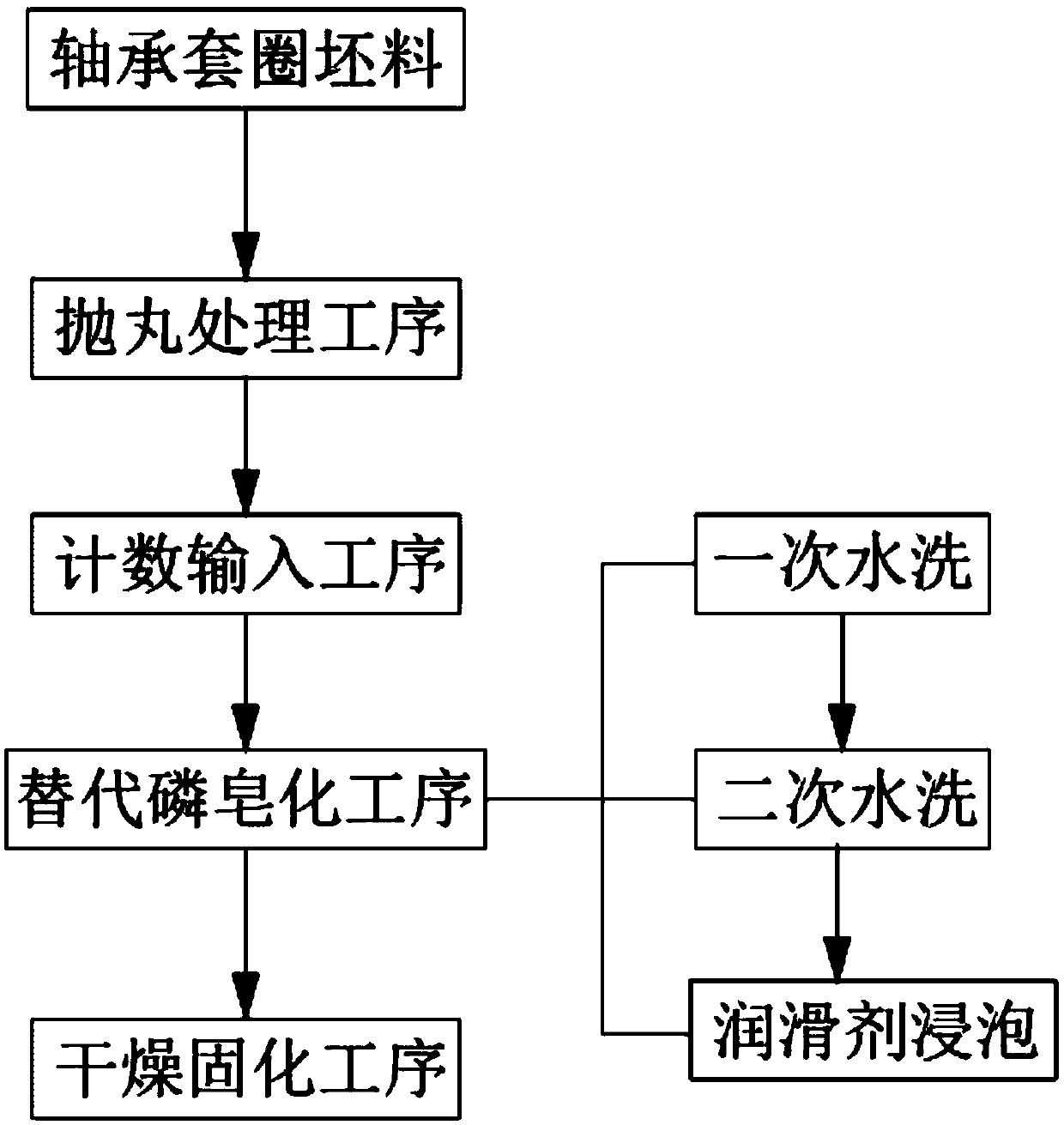

[0044] Such as figure 1 As shown, an environmentally friendly processing technology to replace the phosphorus saponification treatment on the bearing surface, including the following steps:

[0045] Step 1, the shot blasting process, the bearing ring blank is placed in the shot blasting machine for shot blasting, and the oxide layer on the surface of the bearing ring blank is removed;

[0046] Step 2, the counting input process, the bearing ring blanks after shot blasting are input into the water tank of the phosphorus saponification treatment device replacing the bearing surface one by one and in batches through the conveying track, and during the conveying process, through the counter. The input quantity of bearing ring blanks is counted;

[0047] Step 3, instead of the phosphorus saponification process, the bearing ring blank input into the water tank of the phosphorus saponification treatment device for the replacement bearing surface is washed and soaked, then flipped an...

Embodiment 2

[0073] Referring to the first embodiment, the second embodiment of the present invention describes an environmentally friendly processing device that replaces the phosphorus saponification treatment of the bearing surface.

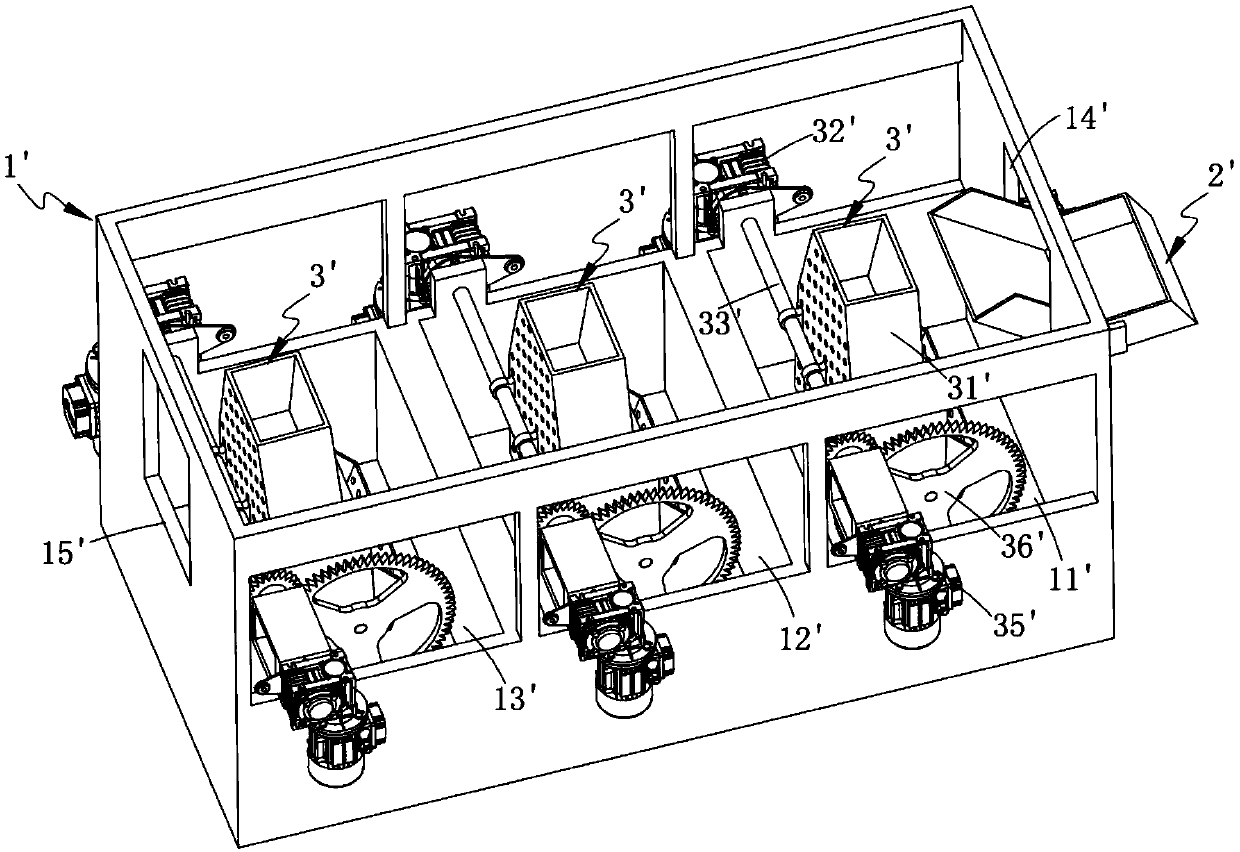

[0074] Such as Figure 2 to Figure 8 As shown, an environmentally friendly processing device that replaces the phosphorus saponification treatment on the bearing surface, including:

[0075] The box body 1', the first water washing tank 11', the second washing tank 12' and the lubrication soaking tank 13' are arranged in the box body 1', the first washing tank 11', the second washing tank 12' and the lubrication soaking tank 13' are arranged along the bearing sleeve The processing order of the ring blanks is arranged in sequence, and the two side walls of the box body 1' are respectively provided with a feed port 14' and a discharge port 15';

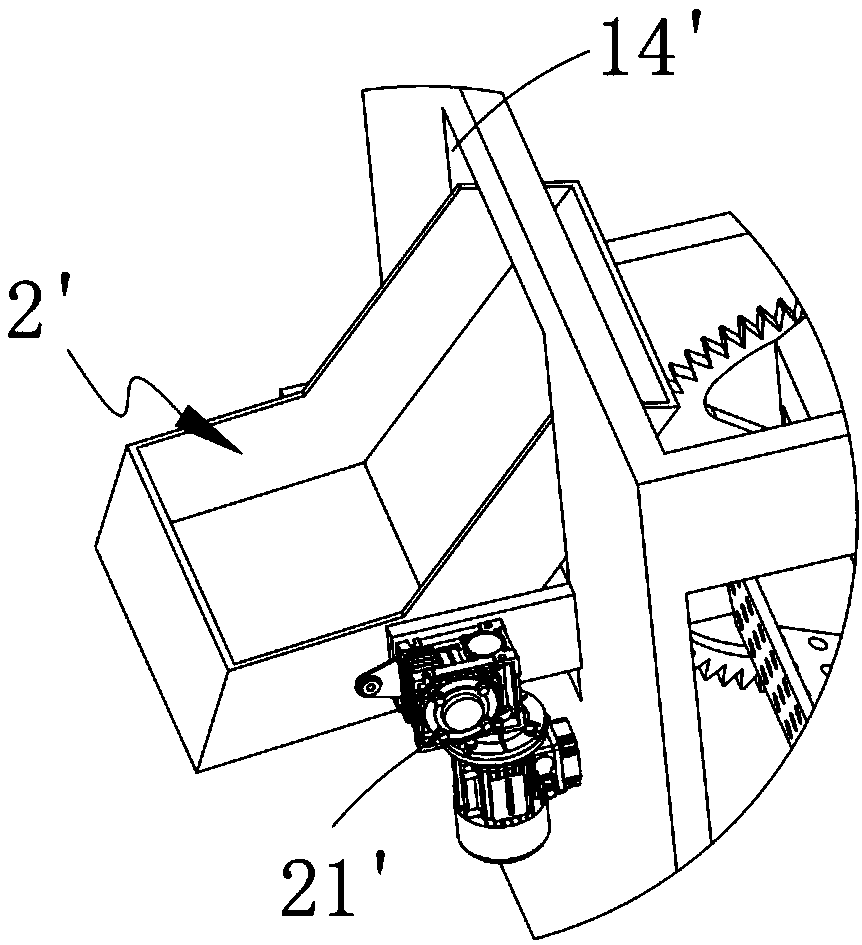

[0076] Feed hopper 2', the feed hopper 2' is set at the feed port 14', it can be rotated with the box body 1', a...

Embodiment 3

[0090] Referring to the first embodiment, the third embodiment of the present invention will describe an automatic conveying line after phosphorus saponification treatment on the bearing surface instead.

[0091] Such as Figure 9 to Figure 10 As shown, an automatic conveying line after phosphorus saponification treatment on the surface of a replacement bearing includes a replacement phosphorus saponification device 1, a connected cold forging device 2 and a bearing ring blank 10 for cold forging treatment, and also includes:

[0092] A connecting device 3, which is arranged between the outlet 11 of the alternative phosphorus saponification device 1 and the one-piece cold forging device 2, which receives the bearing ring blank output by the outlet 11 10 is transported to the one-piece cold forging device 2, and the one-piece cold forging device 2 forges and presses the bearing ring blank 10 into a one-piece blank 21 of inner and outer rings.

[0093] Such as image 3 As show...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap