Micro water jet electric control gun

A technology of jet electricity and micro-water, applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc., can solve the problems of frequent maintenance, high maintenance cost, environmental pollution, etc. The effect of eliminating the intermediate control link and the simple and reliable system operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

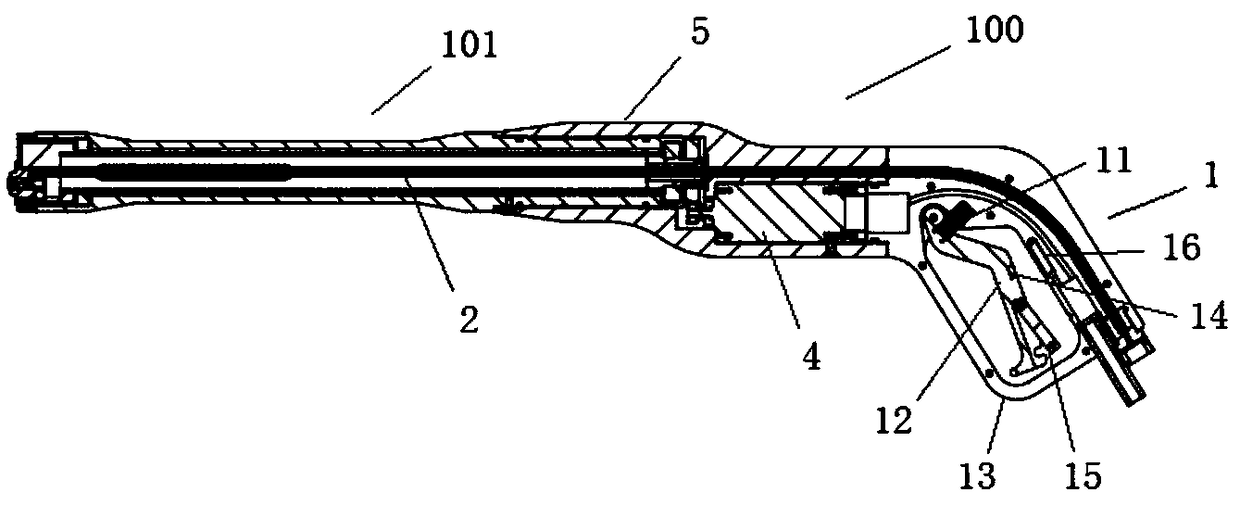

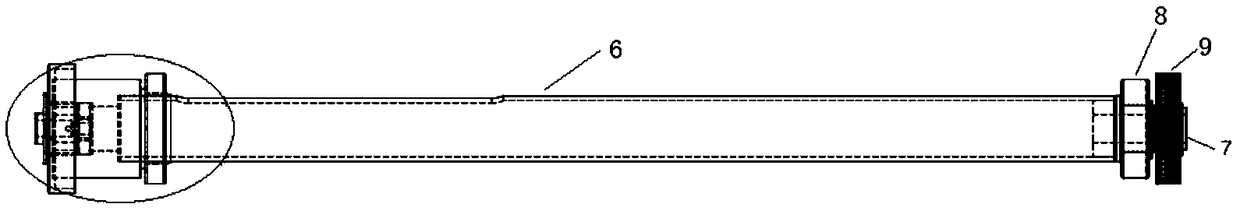

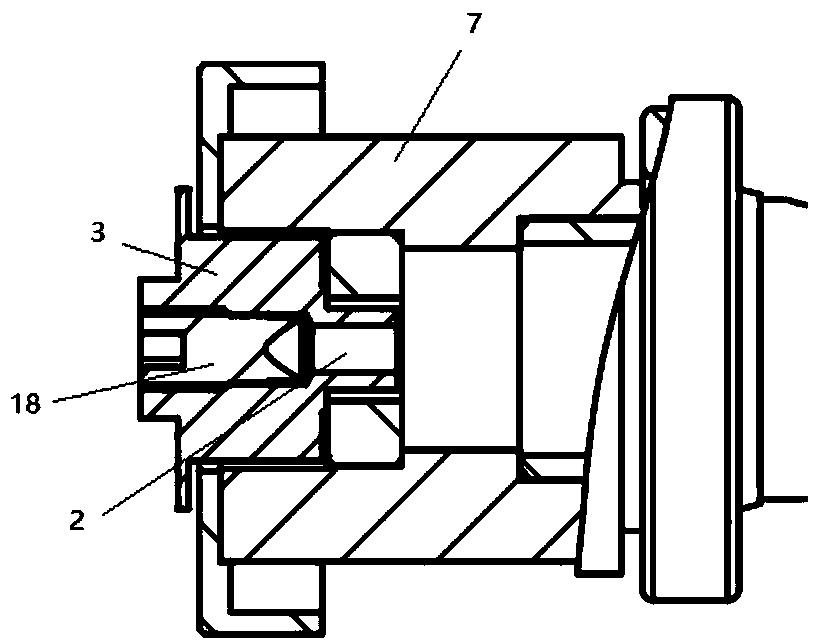

[0034] Such as Figure 1-3 As shown, the micro-water jet electric control gun 100 includes a gun handle 1 and a driving rotation mechanism 101, and the driving rotation mechanism 101 includes an assembly rotation rod 102, a high-pressure hard pipe 2, a nozzle 18, a nozzle base 3, a micro-motor 4 and a transmission Box handle 5.

[0035] Assembling the rotating rod 102 includes the rotating rod 6 and the pressure riveting joints 7 fixed at both ends of the rotating rod 6 . The high-pressure hard pipe 2 extends from the gun handle 1 to the rotating rod 6 in the micro-water jet electric control gun 100. One end of the high-pressure hard pipe 2 is connected with a high-pressure hose (not shown in the figure), and the other end is connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com