Heating device for drying painted parts

A technology for heating devices and paint spray booths, which is applied to devices for coating liquids on surfaces, pretreatment surfaces, coatings, etc., can solve problems such as hidden safety hazards, fire safety accidents, and waste gas environmental pollution, and achieves reduction of power loss, The effect of reducing power consumption and improving environmental quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

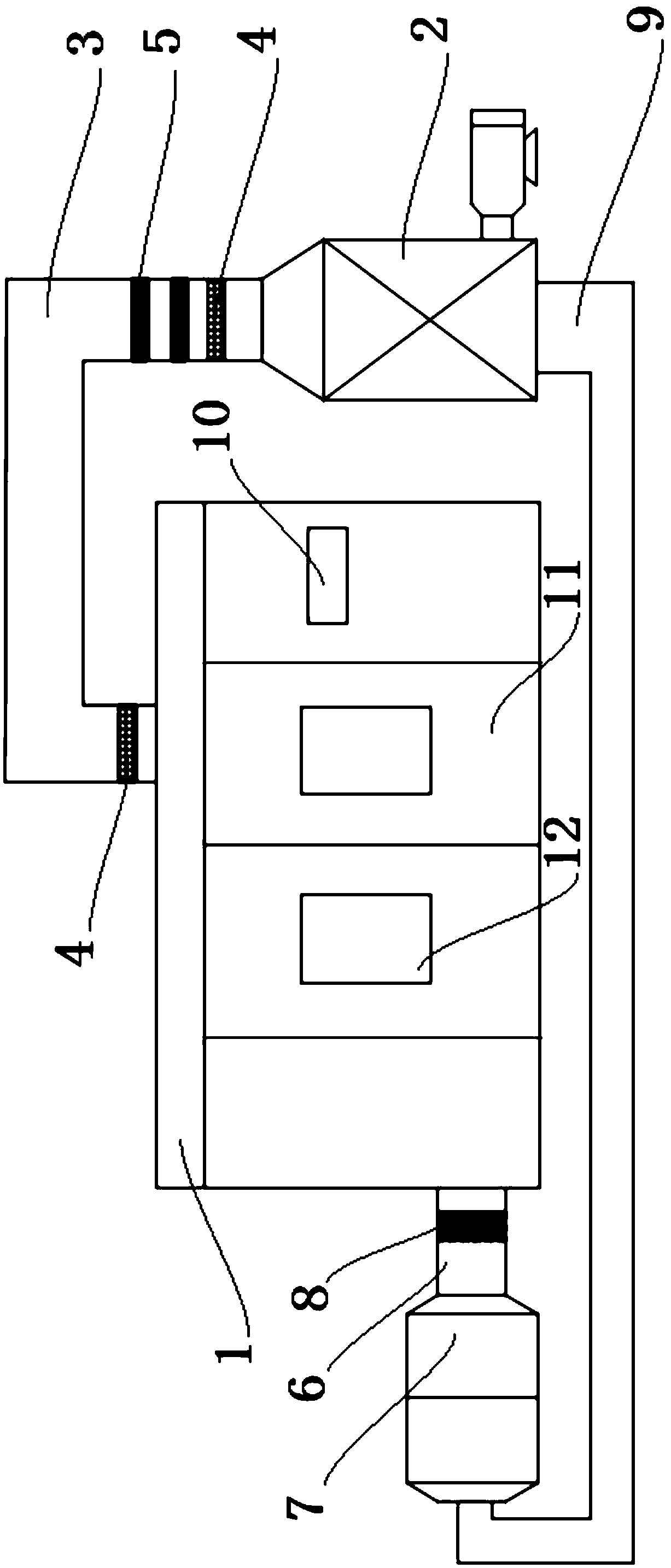

[0019] Such as figure 1 As shown, a heating device for drying painted parts of the present invention includes a paint spray booth 1, and the outside of the paint spray booth 1 is provided with a blower 2 and an electric heater that provides hot air to the paint spray booth 1, and the blower 2 and the electric heater The top of the spray booth 1 is communicated with the air inlet duct 3, and the electric heater is positioned in the air inlet duct 3. The electric heater is preferably a carbon fiber far-infrared heating tube 5, and the carbon fiber far-infrared heating tube 5 is provided with a wiring connected to the wiring port. Column, carbon fiber far-infrared heating tubes 5 are provided with multiple groups, and multiple groups of carbon fiber far-infrared heating tubes 5 are fixedly connected with the inner wall of the air inlet duct 3 at intervals. Carbon fiber far-infrared heating tube 5 is used as an electric heater. Carbon fiber is a pure black body material. The heati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com