Sectional type heating beverage bottle warmer

A segmented, beverage bottle technology, applied to heating devices, cooking utensils, household utensils, etc., can solve the problems of not allowing users to obtain hot water and discomfort for users, and achieve fast heating speed, convenient use and portability , Conducive to the effect of marketing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

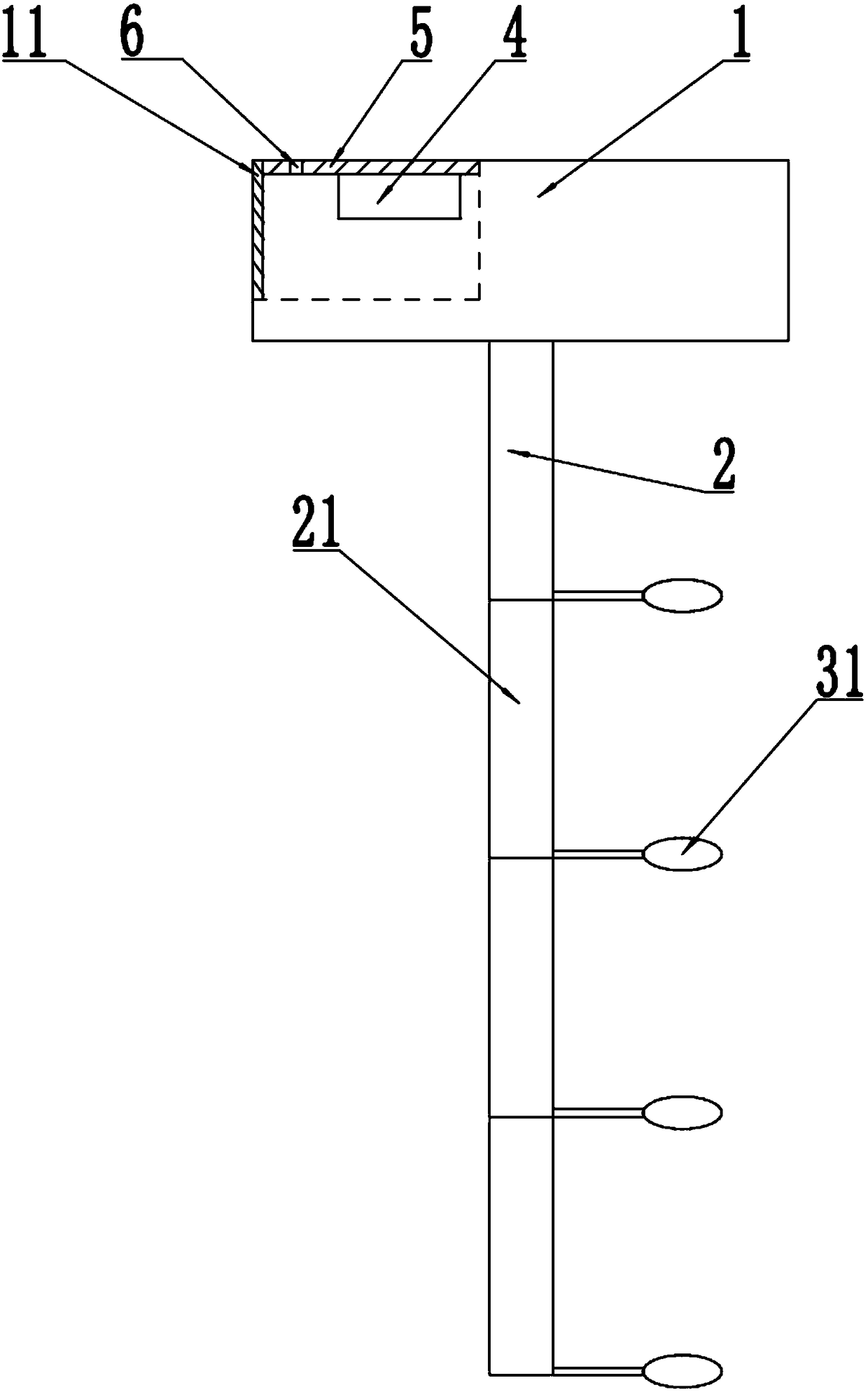

[0024] A segmented heating beverage bottle heater, comprising a cover body 1, a segmented heating module 2, a liquid level detection module 3 and a controller 4, the inner wall of the cover body 1 is provided with an internal thread matching the mouth of the beverage bottle external thread 11, the inner end of the cover 1 is connected to one end of the heating module 2, the liquid level detection module 3 is arranged outside the segmented heating module 2, the controller 4 is installed inside the cover 1, and the segmented heating module 2 and The liquid level detection modules 3 are all electrically connected to the controller 4, specifically, the controller 4 can be an stm32 single-chip microcomputer.

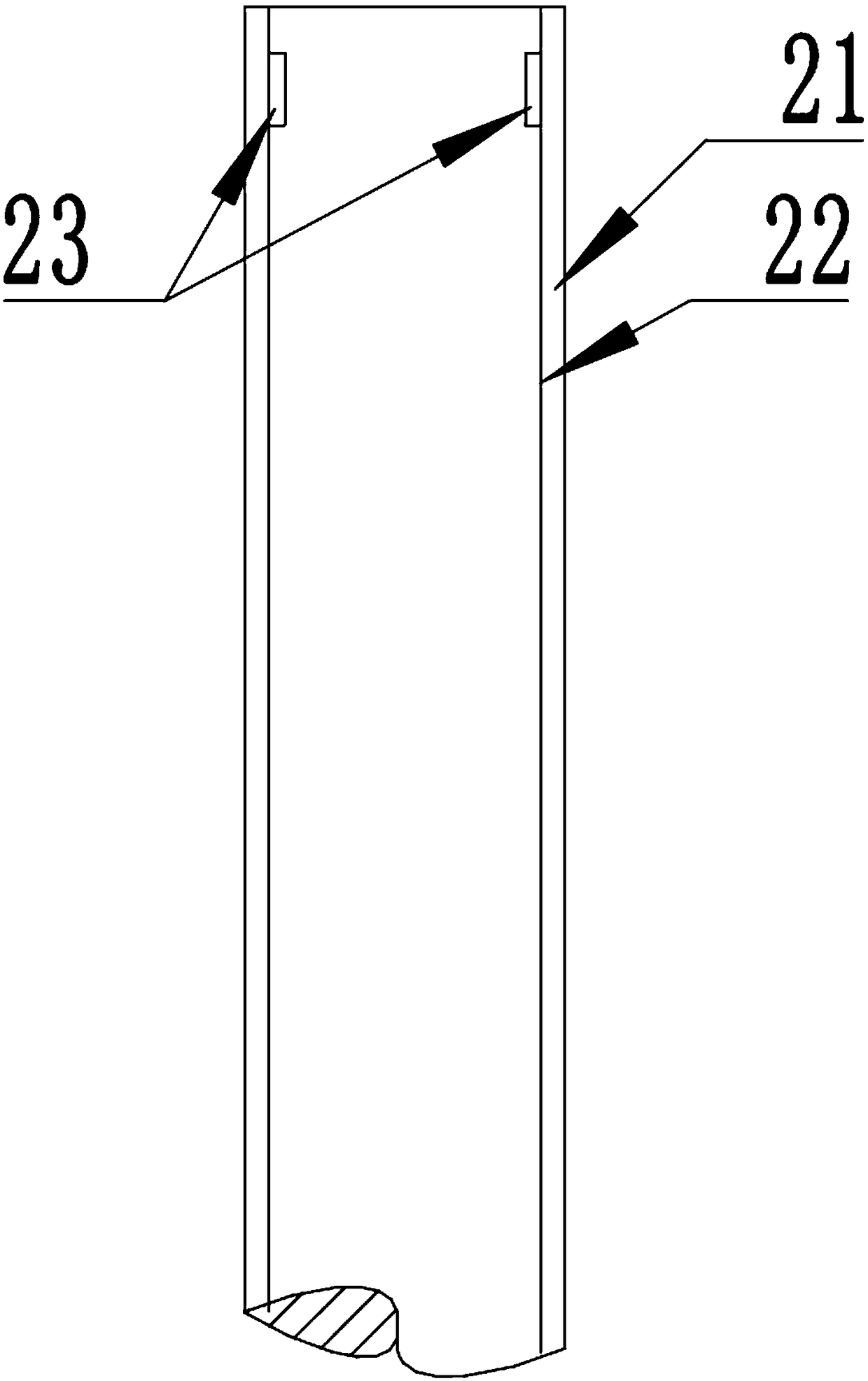

[0025] The segmented heating module 2 is composed of four heating components 21, the heating components 21 are fixedly connected head to tail in turn, the bottom of the uppermost heating component 21 is connected to the top of the second heating component 21, and the bottom of...

Embodiment 2

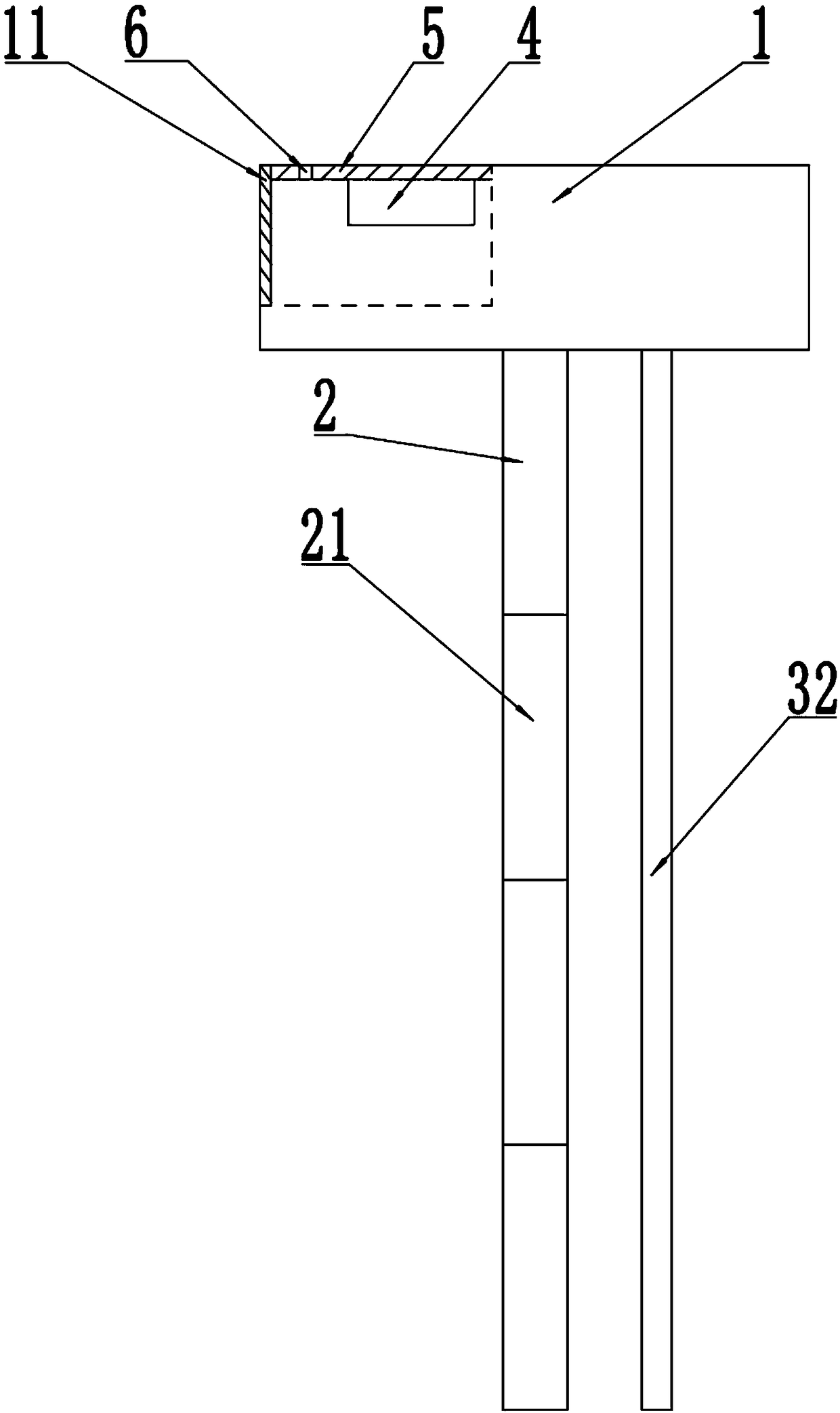

[0033] On the basis of the first embodiment above, the liquid level detection module 3 does not use four float switches 31, but uses an electrode type liquid level gauge 32, and the electrode type liquid level gauge is installed in parallel with the heating module 2, and the length is the same as that of the heating module. 2 is the same.

[0034] When the user is in use, the electrode-type liquid level gauge 32 measures the height of the liquid level and transmits it to the controller 4. The controller 4 controls the opening of the heating element 21 in contact with the liquid according to the height of the liquid level and the installation height of each heating element 21. If the electrode Type liquid level gauge 32 does not detect liquid, then controller 4 controls all heating assemblies 21 to close.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com